He-Ne laser tube with flat inner cavity and manufacturing method thereof

A helium-neon laser and flat technology, which is applied in the field of gas laser tube and its preparation, can solve the problems affecting the application and promotion of high-power flat discharge tube helium-neon laser, increasing the complexity and cost of the laser structure, and affecting the laser output power. Achieve the effect of reducing the cost of the whole machine, prolonging the life, and improving the output power of the laser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

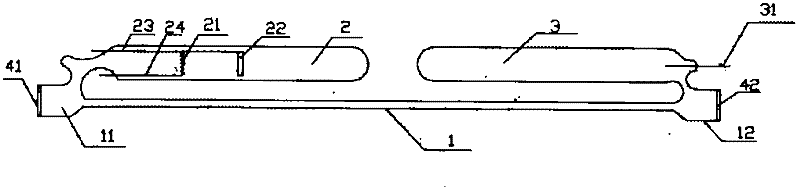

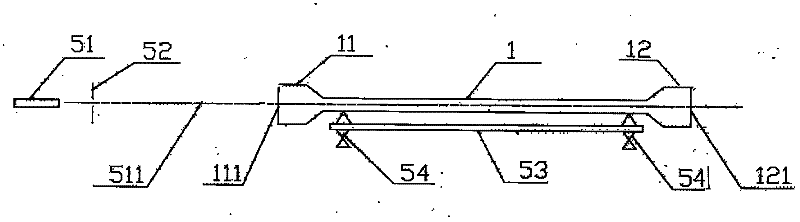

[0024] A flat helium-neon laser tube with an inner cavity of the present invention includes a flat discharge tube 1, a cathode bubble 2, and an anode bubble 3, and the cathode bubble 2 and the anode bubble 3 are respectively welded on the same side of the left and right ends of the flat discharge tube 1; The anode bubble 3 is provided with an anode 31, and the cathode bubble 2 is sealed with a long cathode side bar 23 and a short cathode side bar 24, and a connection is welded between the long cathode side bar 23 and the short cathode side bar 24. Both oxide cathode filaments 21; the two ends of the flat discharge tube 1 are respectively welded with a left mirror tube 11 and a right mirror tube 12, and on the end face of the left mirror tube 11 and the right mirror tube 12 Dielectric film reflectors are respectively arranged on the end surfaces, and the two dielectric film reflectors are respectively a planar dielectric film reflector 41 and a concave spherical dielectric film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com