Catalyst For Purification Of Exhaust Gas

A technology for exhaust gas purification and catalyst, which is applied in physical/chemical process catalysts, catalyst activation/preparation, chemical elements of heterogeneous catalysts, etc. It can solve the problems of inability to obtain OSC and achieve the effect of excellent catalyst performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

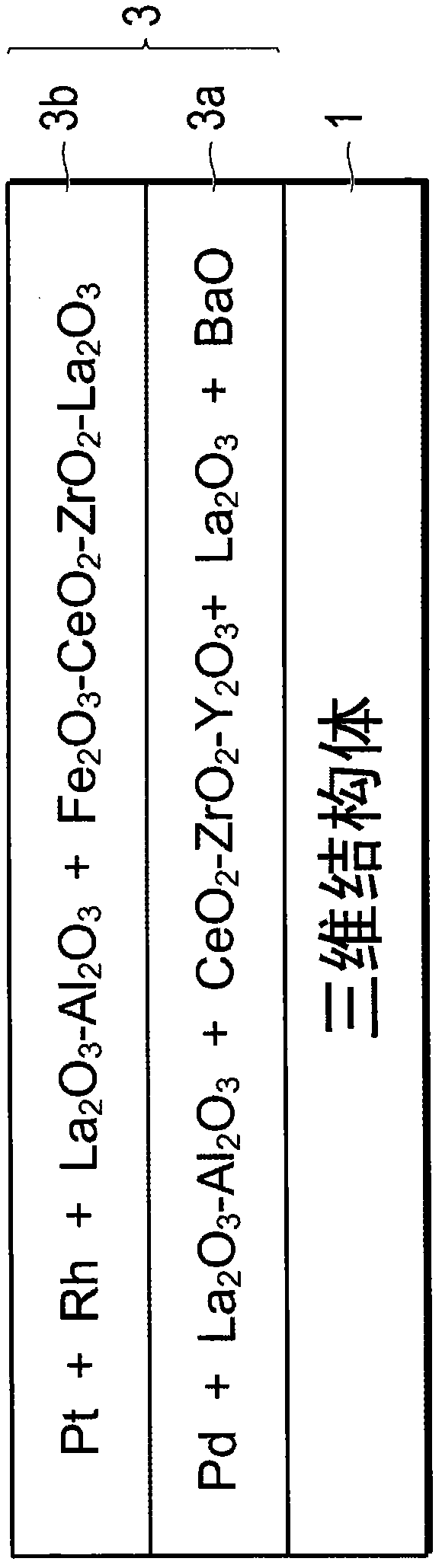

[0074]

[0075] The catalyst of this aspect can be produced, for example, as follows. That is, after contacting the slurry of any one of the catalyst active components with the three-dimensional structure support, it is dried in air at a temperature of 50 to 300°C, preferably at a temperature of 80 to 200°C. 5 minutes to 10 hours, preferably drying for 5 minutes to 8 hours. Then, it is fired at a temperature of 300 to 1200°C, preferably at a temperature of 400 to 500°C, for 30 minutes to 10 hours, preferably for 1 hour to 5 hours. Next, a finished catalyst is obtained by allowing the slurry of any other catalytically active component to be supported in the same manner, and, if necessary, similarly allowing the slurry of any other catalytically active component to be supported.

[0076]

[0077] The catalyst of this embodiment is used for purification of exhaust gas of internal combustion engines, especially gasoline engines. The space velocity (S.V.) at this time is 10,0...

Embodiment 1

[0084] In order to form the lower catalyst layer, first, palladium nitrate as a palladium raw material, alumina containing 3% by weight of lanthanum oxide, barium hydroxide as a barium oxide raw material, and CeO 2 -ZrO 2 -Y 2 o 3 Composite oxides (CeO 2 : ZrO 2 : Y 2 o 3 = 10:80:10 (mass ratio)) each raw material is weighed so that after firing it satisfies Pd:La 2 o 3 :BaO:La 2 o 3 -Al 2 o 3 : CeO 2 -ZrO 2 -Y 2 o 3 =0.4:2:2:80:50 (mass ratio). Then, the weighed raw materials were mixed and stirred for one hour, and then wet pulverized to obtain a slurry I.

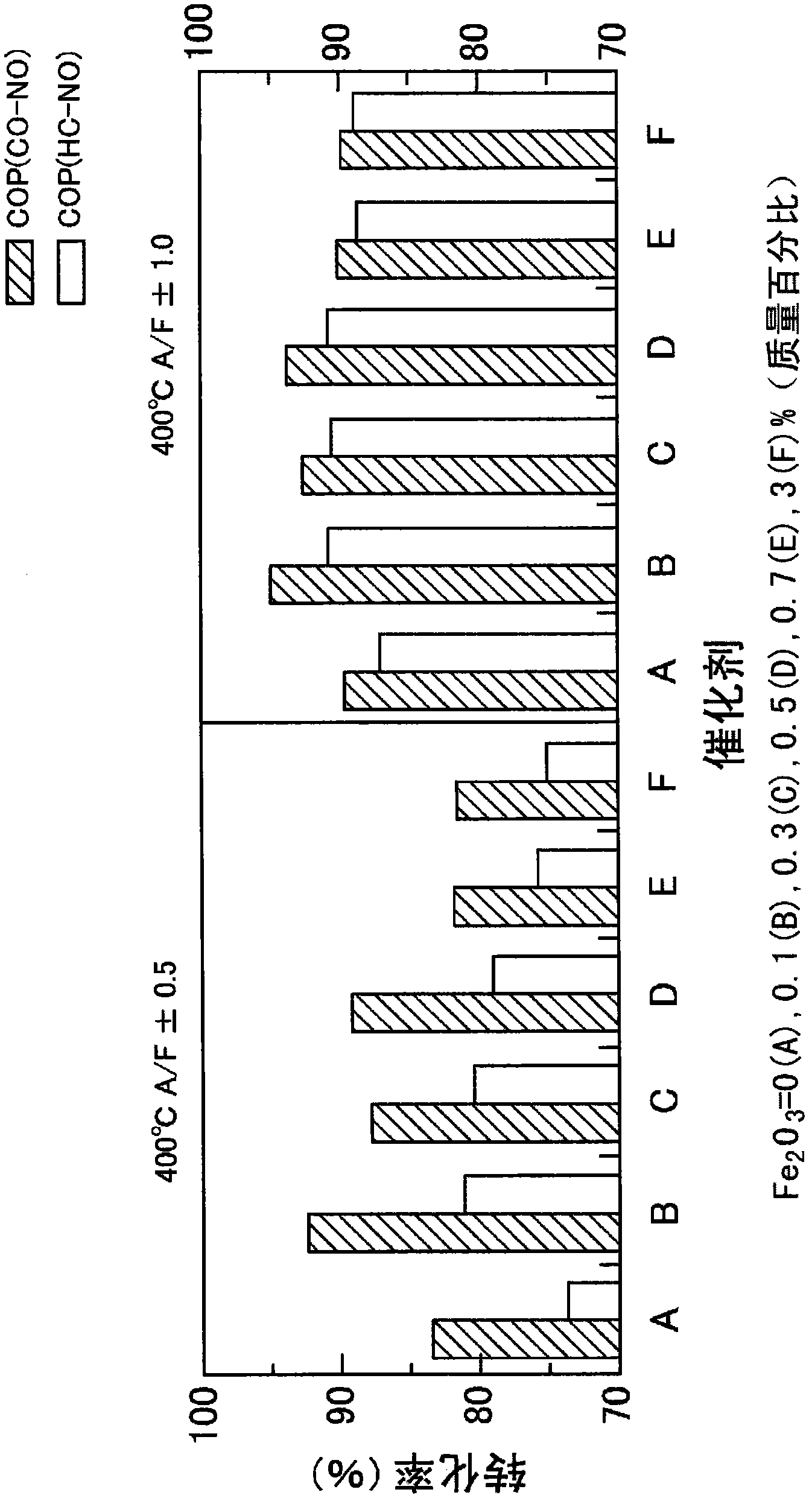

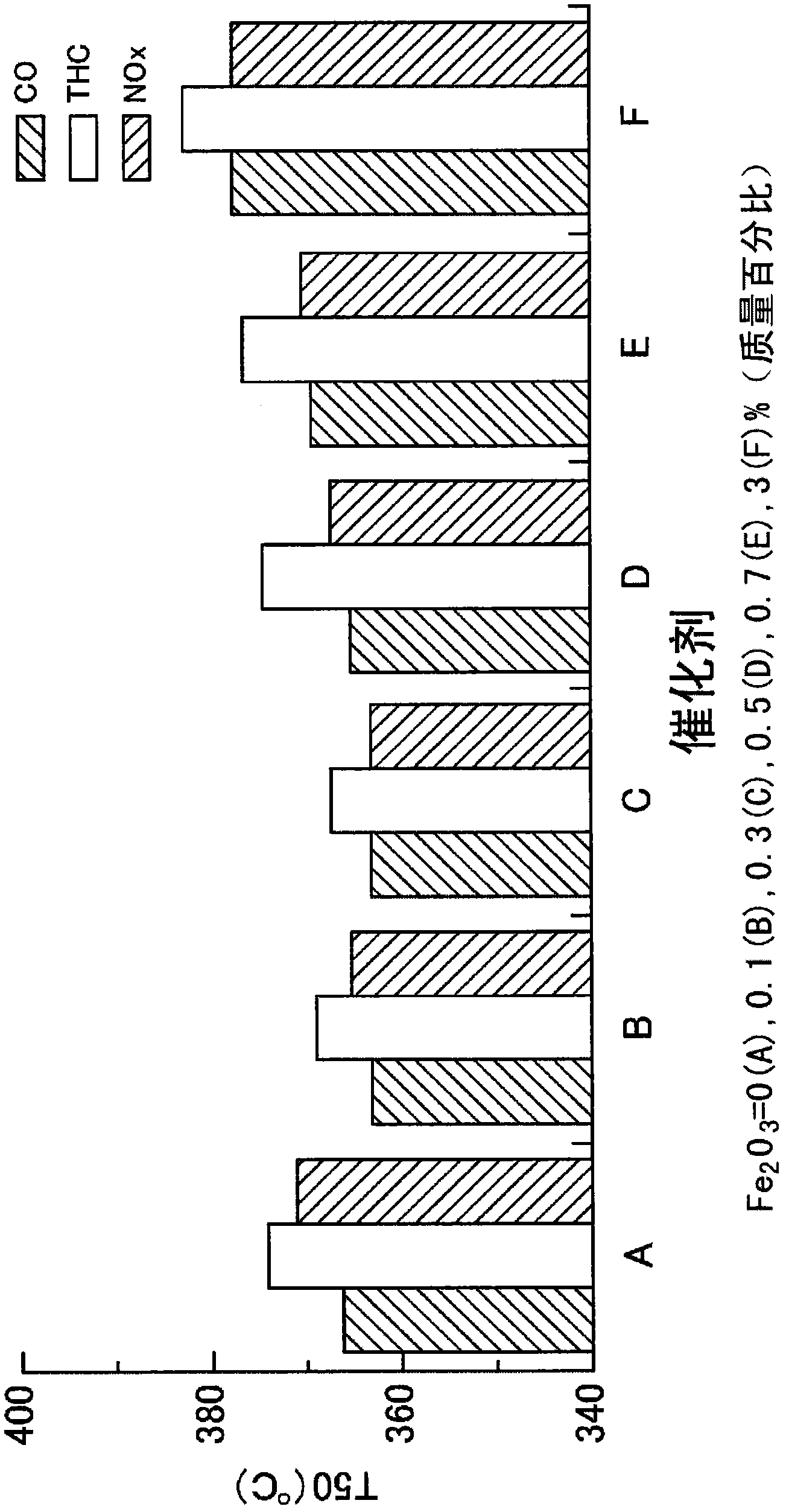

[0085] In addition, in order to form the upper catalyst layer, platinum nitrate as a platinum raw material, rhodium nitrate as a rhodium raw material, alumina containing lanthanum at 3% by weight, and Fe 2 o 3 -CeO 2 -ZrO 2 -La 2 o 3 Composite oxides (Fe 2 o 3 : CeO 2 : ZrO 2 : La 2 o 3 =0.1:30:59.9:10 (mass ratio)) Each raw material is weighed so that after firing it satisfies Pt:Rh:La 2 o ...

Embodiment 2

[0088] Fe to be used in slurry II 2 o 3 -CeO 2 -ZrO 2 -La 2 o 3 The ratio of each component of the composite oxide is Fe 2 o 3 : CeO 2 : ZrO 2 : La 2 o 3 = 0.3:30:59.7:10 (mass ratio), and the same method as in Example 1 was used to prepare catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com