Synthetic method for mesopore titanium-silicon molecular sieve

A technology of titanium-silicon molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of increasing the difficulty of industrial production, complex and harsh synthesis conditions, and long synthesis cycle, so as to solve the problems of energy waste and time consumption, avoid Formation of non-skeletal titanium dioxide, effect of reducing synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

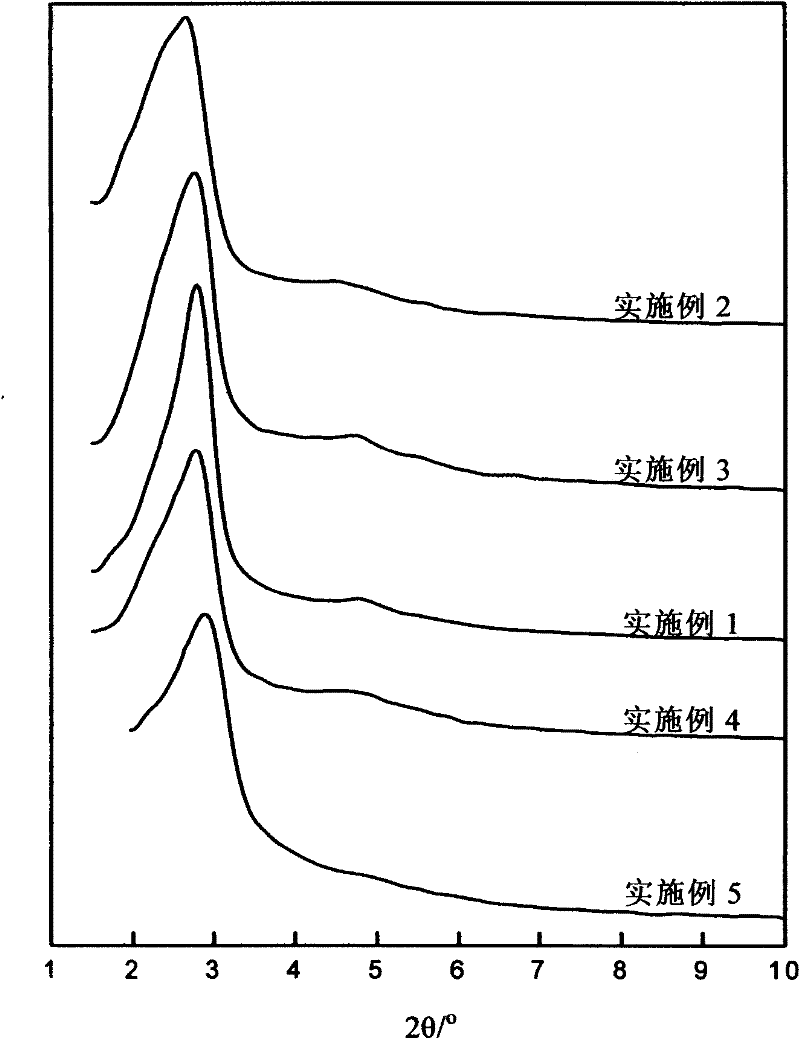

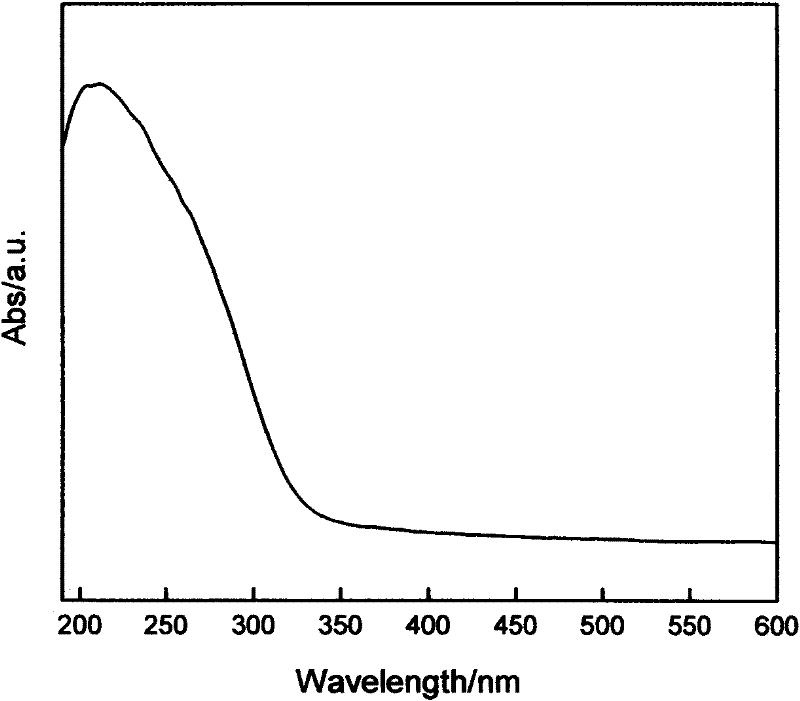

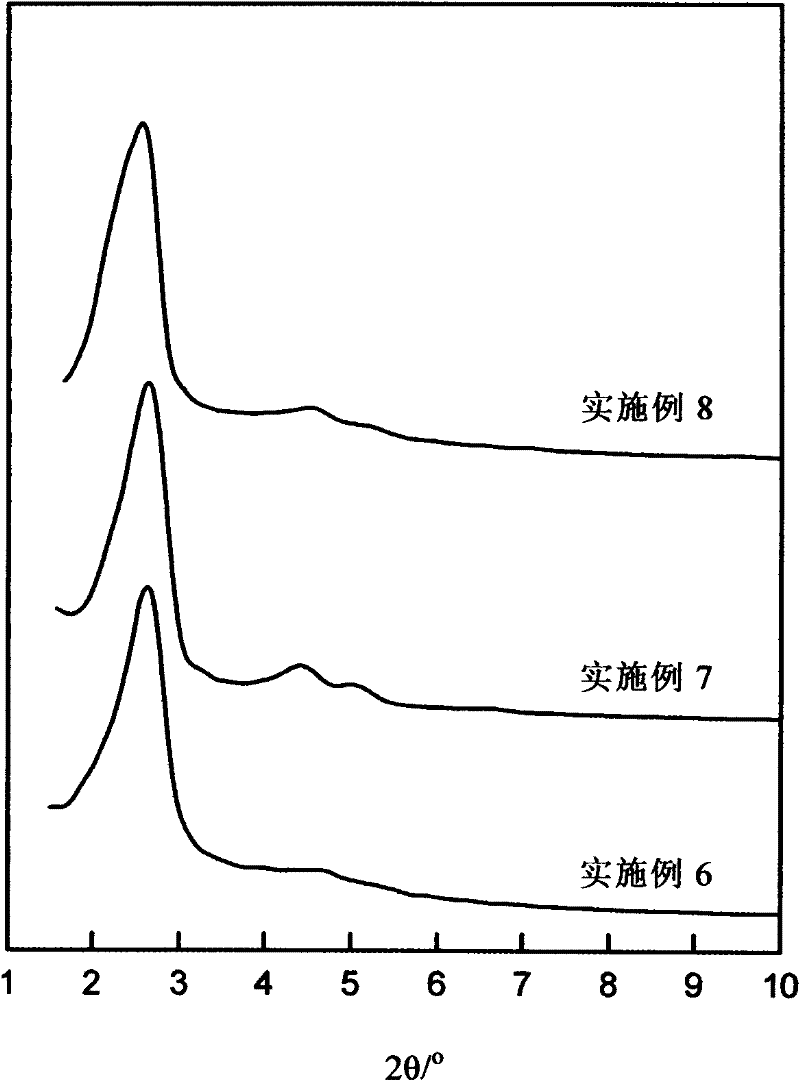

[0038] 18.3g cetyltrimethylammonium bromide was dissolved in 250ml deionized water, stirred at room temperature for 30 minutes; 42.6g water glass (SiO 2 content is 28.26wt%) mixed with 150ml deionized water, slowly added dropwise to cetyltrimethylammonium bromide aqueous solution, while vigorously stirring; 9.1g 17.0wt% TiCl 3 The aqueous solution is mixed with 100ml of deionized water, and slowly added dropwise to the above mixed solution while vigorously stirring; wherein the molar ratio of the silicon source, the titanium source, and the template agent is 1:0.05:0.25. Adjust the pH value of the system to 9.5 with dilute hydrochloric acid solution; continue to stir and crystallize at 20°C for 5 hours. The solid product was separated from the mother liquor, washed with deionized water until neutral, dried in air at 110°C for 5 hours; finally calcined at 550°C for 6 hours to obtain Ti-MCM-41 mesoporous molecular sieve. Its specific surface area is 1067m 2 / g; Its X-ray diffr...

Embodiment 2

[0040] 18.3g cetyltrimethylammonium bromide was dissolved in 250ml deionized water, stirred at room temperature for 30 minutes; 42.6g water glass (SiO 2 content is 28.26wt%) mixed with 150ml deionized water, slowly added dropwise to cetyltrimethylammonium bromide aqueous solution, while vigorously stirring; 9.1g 17.0wt% TiCl 3 The aqueous solution is mixed with 100ml of deionized water, and slowly added dropwise to the above mixed solution while vigorously stirring; wherein the molar ratio of the silicon source, the titanium source, and the template agent is 1:0.05:0.25. Adjust the pH value of the system to 8.0 with dilute hydrochloric acid solution; continue to stir and crystallize at 20°C for 5 hours. The solid product was separated from the mother liquor, washed with deionized water until neutral, dried in air at 110°C for 5 hours; finally calcined at 550°C for 6 hours to obtain Ti-MCM-41 mesoporous molecular sieve. Its specific surface area is 1062m 2 / g; Its X-ray diffr...

Embodiment 3

[0042] 18.3g cetyltrimethylammonium bromide was dissolved in 250ml deionized water, stirred at room temperature for 30 minutes; 42.6g water glass (SiO 2 content is 28.26wt%) mixed with 150ml deionized water, slowly added dropwise to cetyltrimethylammonium bromide aqueous solution, while vigorously stirring; 9.1g 17.0wt% TiCl 3 The aqueous solution is mixed with 100ml of deionized water, and slowly added dropwise to the above mixed solution while vigorously stirring; wherein the molar ratio of the silicon source, the titanium source, and the template agent is 1:0.05:0.25. Adjust the pH value of the system to 9.0 with dilute hydrochloric acid solution; continue to stir and crystallize at 20°C for 5 hours. The solid product was separated from the mother liquor, washed with deionized water until neutral, dried in air at 110°C for 5 hours; finally calcined at 550°C for 6 hours to obtain Ti-MCM-41 mesoporous molecular sieve. Its specific surface area is 1079m 2 / g; Its X-ray diffr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com