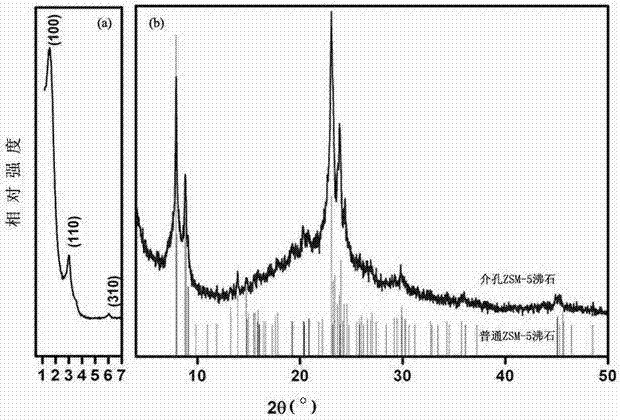

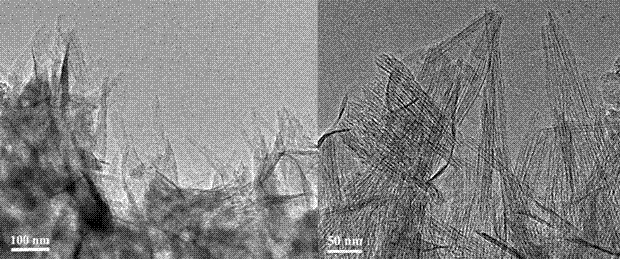

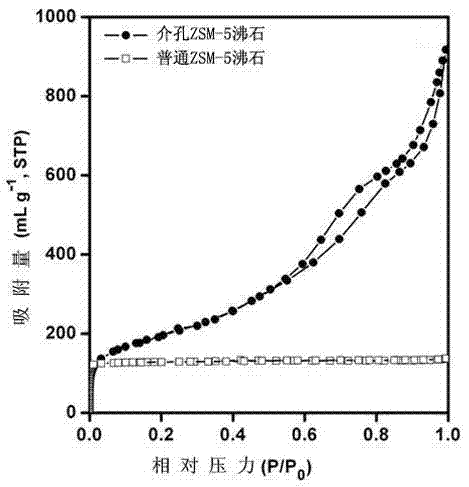

Preparation method for mesoporous ZSM-5 zeolite molecular sieve

A technology of ZSM-5 and zeolite molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of not fundamentally improving the acidity and hydrothermal stability of mesoporous materials, etc. Problems, to achieve the effect of low cost, increase crystallinity, easy to obtain and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 1.189g (0.0012mol) of triammonium-based quaternary ammonium salt surfactant and 5.6mL of ethanol in 12mL of water to form liquid A, mix 0.111g (0.0012mol) of sodium metaaluminate and 0.36g (0.009mol) Sodium hydroxide was dissolved in 19.5mL of water to obtain liquid B;

[0032] (2) Under the condition of stirring, add liquid A to liquid B to form liquid C;

[0033] (3) Under magnetic stirring at 60°C, slowly add 5.077g (0.024mol) ethyl orthosilicate dropwise into liquid C to form a gel, continue stirring for 6 hours, and age at 50°C for 12 hours;

[0034] (4) Put the product of step (3) into a sealed crystallization reaction kettle, crystallize at 150°C for 120 hours, wash, filter, and dry, and then calcinate in air at 550°C for 6 hours to remove the template agent, and obtain intermediate Pore ZSM-5 zeolite molecular sieve.

Embodiment 2

[0036] (1) Dissolve 0.797g (0.0008mol) of triammonium-based quaternary ammonium salt surfactant and 3.8mL of ethanol in 9mL of water to form liquid A, mix 0.075g (0.0008mol) of sodium metaaluminate and 0.24g (0.006mol) Sodium hydroxide was dissolved in 12mL of water to obtain liquid B;

[0037] (2) Under the condition of stirring, add liquid A to liquid B to form liquid C;

[0038] (3) Under magnetic stirring at 60°C, slowly add 3.418g (0.016mol) ethyl orthosilicate dropwise into liquid C to form a gel, continue stirring for 6 hours, and age at 60°C for 10 hours;

[0039] (4) Put the product of step (3) into a sealed crystallization reaction kettle, crystallize at 140°C for 96 hours, wash, filter, and dry, then calcinate in air at 550°C for 5 hours to remove the template agent, and obtain intermediate Pore ZSM-5 zeolite molecular sieve.

Embodiment 3

[0041] (1) Dissolve 1.487g (0.0015mol) of triammonium-based quaternary ammonium salt surfactant and 7mL of ethanol in 18mL of water to form a liquid A, mix 0.139g (0.0015mol) of sodium metaaluminate and 0.44g (0.011mol) of hydrogen Sodium oxide was dissolved in 21.4mL of water to obtain liquid B;

[0042] (2) Under the condition of stirring, add liquid A to liquid B to form liquid C;

[0043] (3) Under magnetic stirring at 60°C, slowly add 6.346g (0.03mol) ethyl orthosilicate dropwise into liquid C to form a gel, continue to stir for 6 hours, and age at 50°C for 12 hours;

[0044] (4) Put the product of step (3) into a sealed crystallization reaction kettle, crystallize at 140°C for 120 hours, wash, filter, and dry, then calcinate in air at 550°C for 6 hours to remove the template agent, and obtain intermediate Pore ZSM-5 zeolite molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com