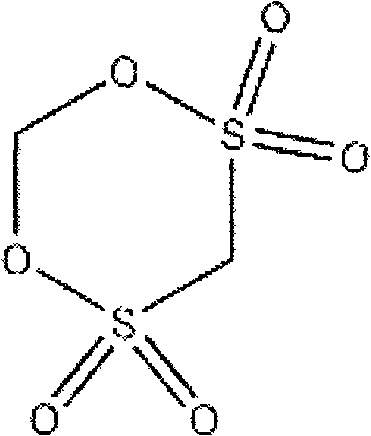

Preparation method of methylene-cyclo methane-disulfonate

A technology of methylene disulfonate and methylene disulfonic acid, which is applied in the direction of organic chemistry, can solve the problems of low yield and no industrial value, and achieve high yield, low cost and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

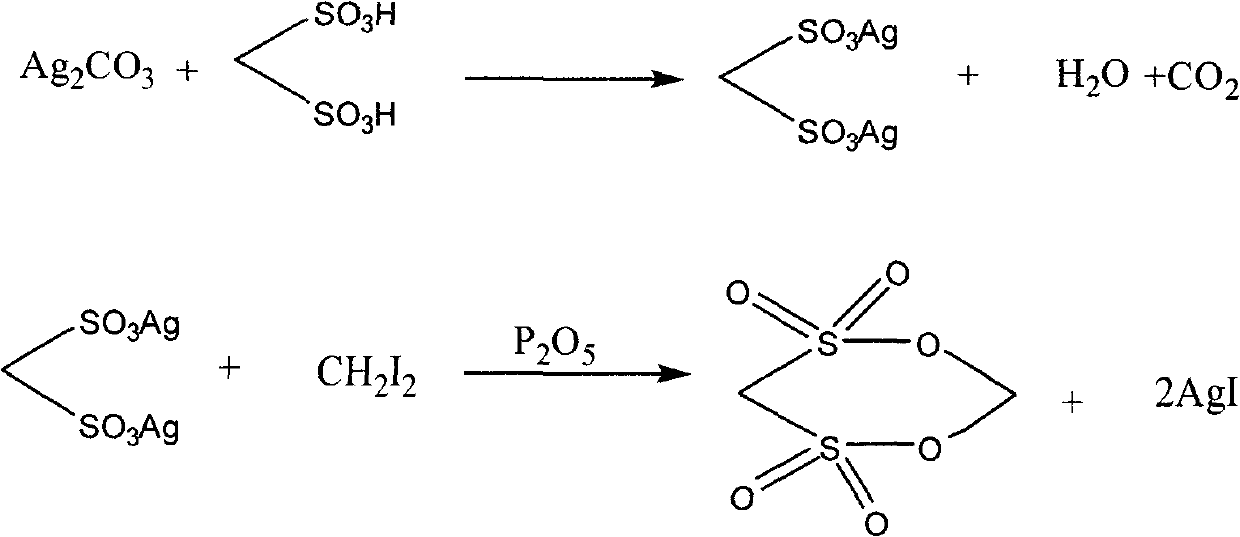

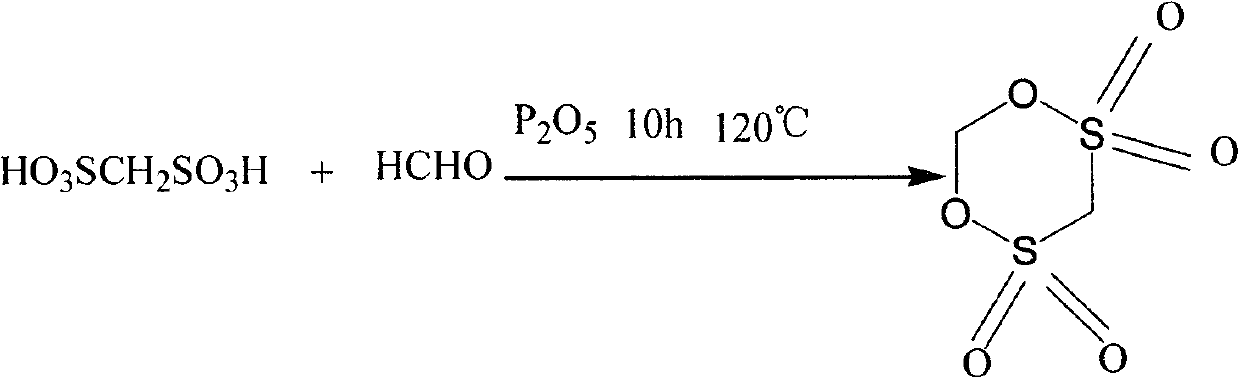

Method used

Image

Examples

Embodiment 1

[0021] The utensil used in the production of methylene disulfonate is a 500ml four-necked flask, which is equipped with a mechanical stirrer, a thermometer, and a dropping funnel. Put 18g of solid methylene disulfonic acid into a four-neck flask, heat up to 110°C, add 23.8g of acylating reagent thionyl chloride dropwise with a dropping funnel, keep the reaction for 6 hours after the dropwise addition, and then cool down to 0 ℃, reduced pressure (10mmHG) for 1 hour, and then raised the temperature to 120°C, then added 3.3 g of cyclization reagent paraformaldehyde to the four-necked flask, and reacted for 24 hours. After the reaction was completed and cooled to room temperature, the extraction solvent was added to the four-necked flask Extract three times with 200ml of chloroform, add 1g of activated carbon to the combined extract to reflux for decolorization for 1 hour, then suction filter, concentrate, and then quickly cool down to crystallize after concentration, the crystalli...

Embodiment 2

[0024] Put 18g of solid methylene disulfonic acid into a 500ml four-necked flask, heat up to 40°C, add 6.85g of acylating reagent phosphorus trichloride dropwise, keep this temperature after the dropwise addition, react for 9 hours, and then add Add 200ml of organic solvent dichloromethane into the bottle mouth, add 8g of methylal, continue to keep the temperature at 40°C for reflux reaction for 20 hours, after the reaction is completed, add 1g of activated carbon to reflux for decolorization for 1 hour, then suction filter, concentrate, and then gradient cooling crystallization after concentration , the crystallization temperature was at -10°C, the crystallization time was 6 hours, and then filtered, and after drying under reduced pressure, 14.3 g of white crystals of fine methylene disulfonate were obtained, with a yield of 76.1%. The nuclear magnetic spectrum was 1 H-NMR (400 MHz, CD3CN) δ (ppm): 5.33 (s, 2H), 6.00 (s, 2H).

[0025] In the above-mentioned reaction of the pr...

Embodiment 3

[0027] Add 300ml of chloroform into a 500ml four-necked flask, then add 18g of methylene disulfonic acid solid, raise the temperature to 62°C, add 10.4g of acylating reagent phosphorus pentachloride, and keep the reaction for 16 hours. After the reaction was completed, keep the temperature and then add 4 g of paraformaldehyde into the four-necked flask, and reflux for 10 hours. After the reaction is completed, add 1 g of activated carbon to reflux for decolorization for 1 hour, then filter with suction, concentrate, and then cool down to crystallize after concentration. The crystallization temperature is 0°C, and the crystallization time is 4 hours. 11.6g of white crystals of cyclomethylene acid, the yield is 61.7%, and the nuclear magnetic spectrum is 1 H-NMR (400 MHz, CD3CN) δ (ppm): 5.33 (s, 2H), 6.00 (s, 2H).

[0028] In the above-mentioned reaction of the present embodiment, the organic solvent can also be one or a mixture of dichloromethane, carbon tetrachloride, ethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com