Polyvinyl chloride brine extraction-resistant membrane for anti-osmosis salt industry

A technology of polyvinyl chloride and impermeability, which is applied in the field of polyvinyl chloride anti-brine extraction and anti-infiltration salt industry membranes, which can solve the problems of film hardening and achieve the effects of improved performance, improved brine resistance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The polyvinyl chloride anti-brine anti-permeation film for the salt industry is composed of the following components: (A) 100 parts by weight of polyvinyl chloride resin; (B) dioctyl phthalate 10PHR (according to 100 parts by weight of resin (C) epoxy soybean oil 2PHR; (D) dioctyl adipate 2PHR; (E) heat stabilizer 2PHR; (F) carbon black 1PHR; ( G) 2-hydroxy-4-n-octyloxybenzophenone 0.1PHR; (H) 4,4-isopropylidene bisphenol 0.1PHR; (I) nitrile rubber 1PHR; (J) trimellitic acid- 2 Ethyl-hexyl ester 10PHR. Wherein, wherein, heat stabilizer selects liquid stabilizer and metal soap stabilizer compound use for use, liquid stabilizer selects barium cadmium zinc compound stabilizer for use, metal soap class stabilizer selects barium stearate and zinc stearate compound use for use. The heat stabilizer ratio is: liquid barium cadmium zinc composite stabilizer 1.5PHR, barium stearate 0.3PHR and zinc stearate 0.2PHR. In this example, in the plasticizer system, part of dioctyl...

Embodiment 2

[0030] The polyvinyl chloride anti-brine anti-permeation film for the salt industry is composed of the following components: (A) 100 parts by weight of polyvinyl chloride resin; (B) dioctyl phthalate 40PHR (according to 100 parts by weight of resin (C) epoxy soybean oil 10PHR; (D) dioctyl adipate 12PHR; (E) heat stabilizer: liquid barium cadmium zinc composite stabilizer 3.5PHR , barium stearate 1PHR and zinc stearate 0.5PHR; (F) carbon black 4PHR; (G) 2-hydroxy-4-methylbenzophenone 0.6PHR; (H) 4,4-isopropylidene bis Phenol 0.8PHR; (I) nitrile rubber 10PHR; (J) trimellitic acid-2 ethyl-hexyl ester 40PHR.

Embodiment 3

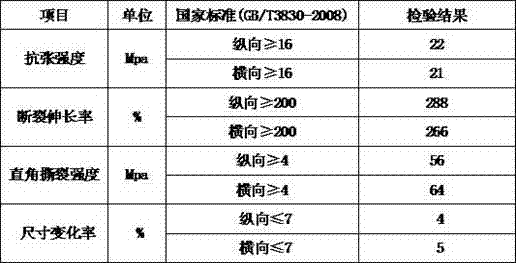

[0032] Polyvinyl chloride brine-resistant anti-permeation film for salt industry. The components are shown in Table 1. The film-making process: After weighing the components according to 1 in Table 1, stir with a high-speed mixer for 270s, and discharge at about 92°C. Then, it is internally mixed by a 10,000-horsepower machine, and then fully mixed in two open plastic mixers. After being filtered by the extruder, it is rolled into a film by a four-roller calender. The formed film is drawn, stretched and then cooled. Shaped into the desired product. The physical properties of the tested products are shown in Table 2.

[0033] After weighing each component in 2 in Table 1, produce according to the process method of the above-mentioned embodiment, the obtained polyvinyl chloride brine-resistant anti-permeation salt industry membrane solves the problem that the anti-permeation salt industry membrane product is used for a long time. Soaked in brine, the plasticizer in the film is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com