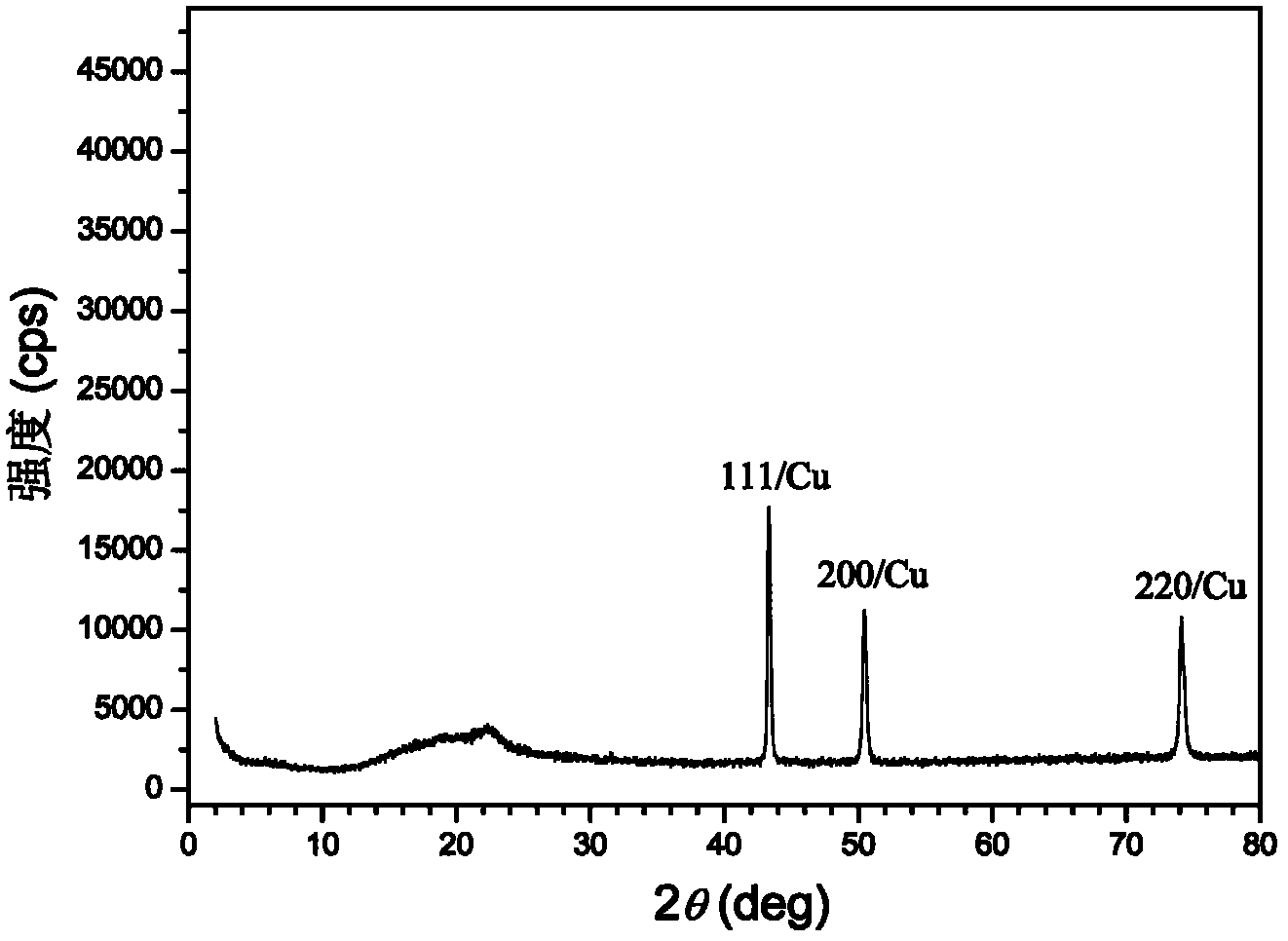

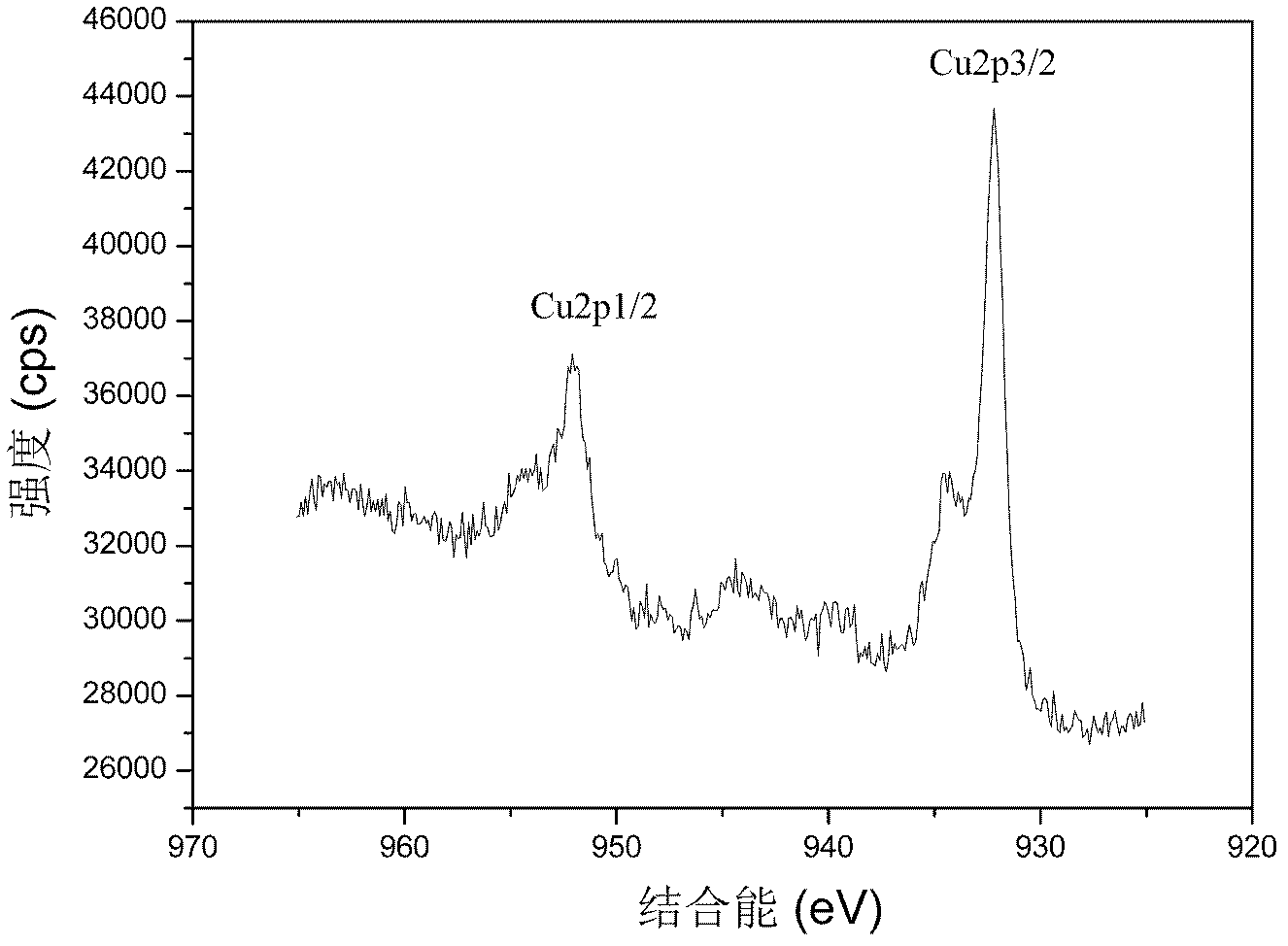

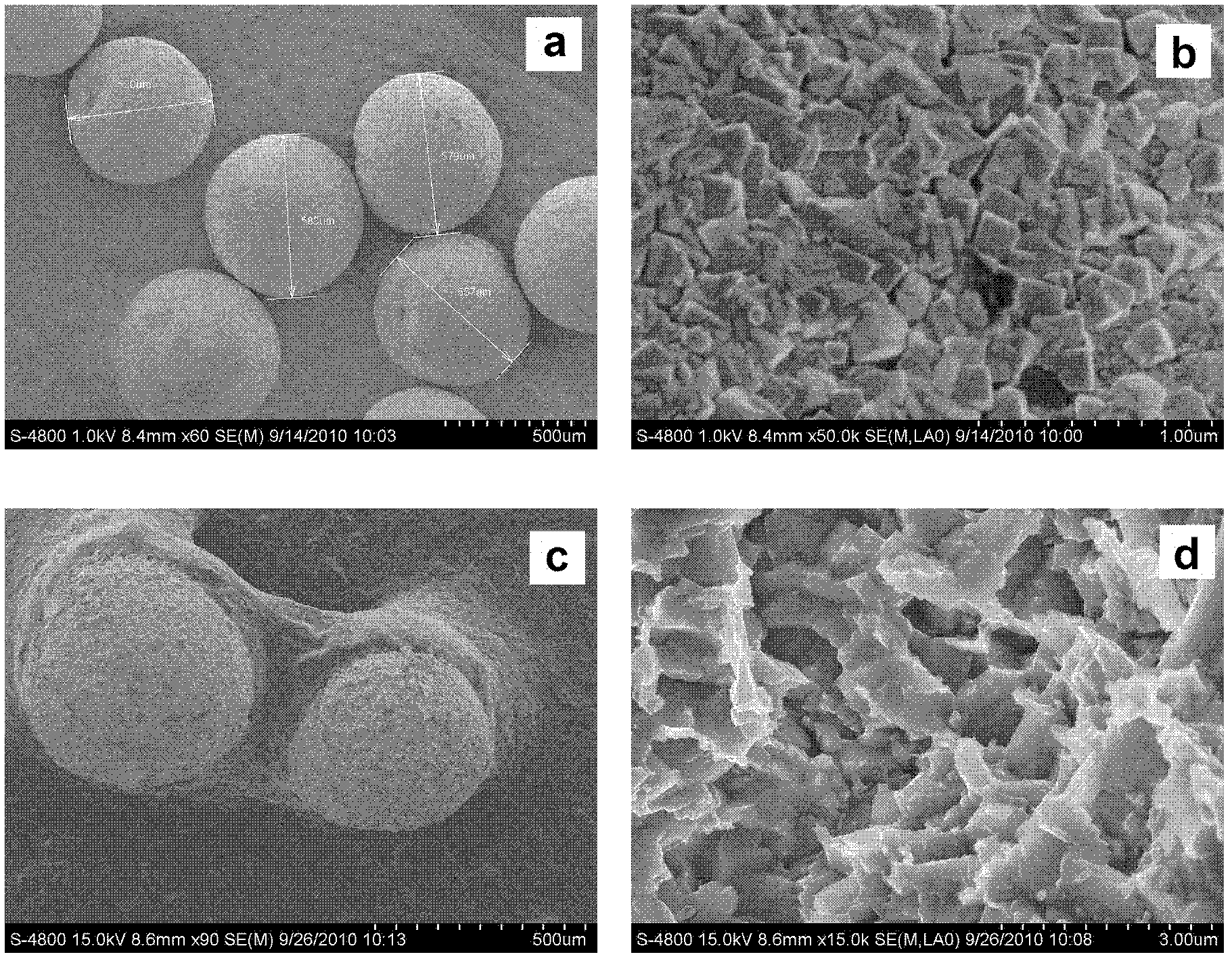

Cu/Cu2O core-shell composite microsphere and preparation method thereof

A technology of core-shell composite microspheres and composite microspheres, which is applied in the field of Cu/Cu2O core-shell composite microspheres and its preparation, can solve the problems of high toxicity of raw materials, difficulty in recycling, and environmental pollution, and is beneficial to non-toxic production and Environmental protection, solve the effect that is not easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 0.02 mol of copper chloride in 20 mL of water to prepare a copper chloride solution; in addition, dissolve 1 g of sodium dodecyl sulfonate and 0.0133 mol of glucose in 30 mL of ethylene glycol to prepare dodecyl sulfonate Sodium-glucose-glycol solution; then mix the copper chloride solution with the sodium lauryl sulfonate-glucose-glycol solution, add it to a flask with a reflux device, stir evenly, and prepare copper chloride -Sodium dodecyl sulfonate-glucose-ethylene glycol-water mixture.

[0032] (2) Dissolve 0.04 moles of sodium hydroxide in 10 mL of water, and then add 30 mL of ethylene glycol to prepare a sodium hydroxide-ethylene glycol-water mixture.

[0033] (3) Under stirring, add the mixture prepared in step (2) to the flask in step (1), and under the protection of nitrogen, heat to reflux temperature, reflux for 48 hours, stop stirring and heating.

[0034] (4) Let the product obtained in the previous step stand at room temperature for 15 hours, then ...

Embodiment 2、 example 3、 example 4

[0038] The reflow time in step (3) in Example 1 was changed to 12h, 24h, 36h, and the other operations were the same as in Example 1. The resulting Cu / Cu 2 The average particle size of the O core-shell composite microspheres were 348μm, 378μm, and 400μm respectively.

Embodiment 5

[0040] Step (1) C in Example 1 6 H 12 O 6 The dosage was changed to 0.01 mole, the other steps were the same as in Example 1, and the product obtained was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com