Flame-retardant degradable adhesive tape and preparation method thereof

A tape, alcoholysis technology, applied in the direction of adhesives, film/sheet adhesives, pressure-sensitive films/sheets, etc. problems, to achieve broad market application prospects, to solve the single method of recycling and reproduction, and to achieve the effect of low-carbon and green use of recycling and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

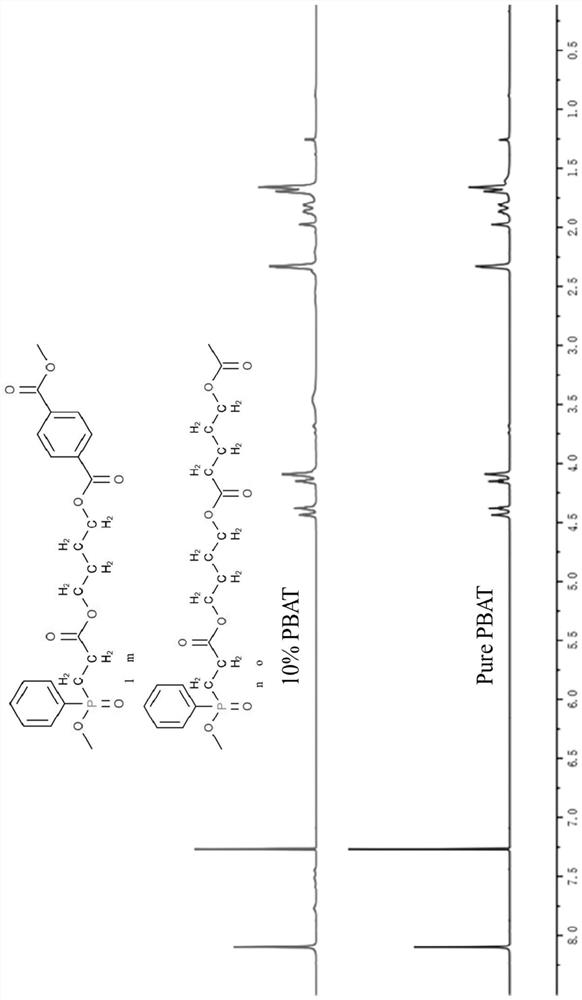

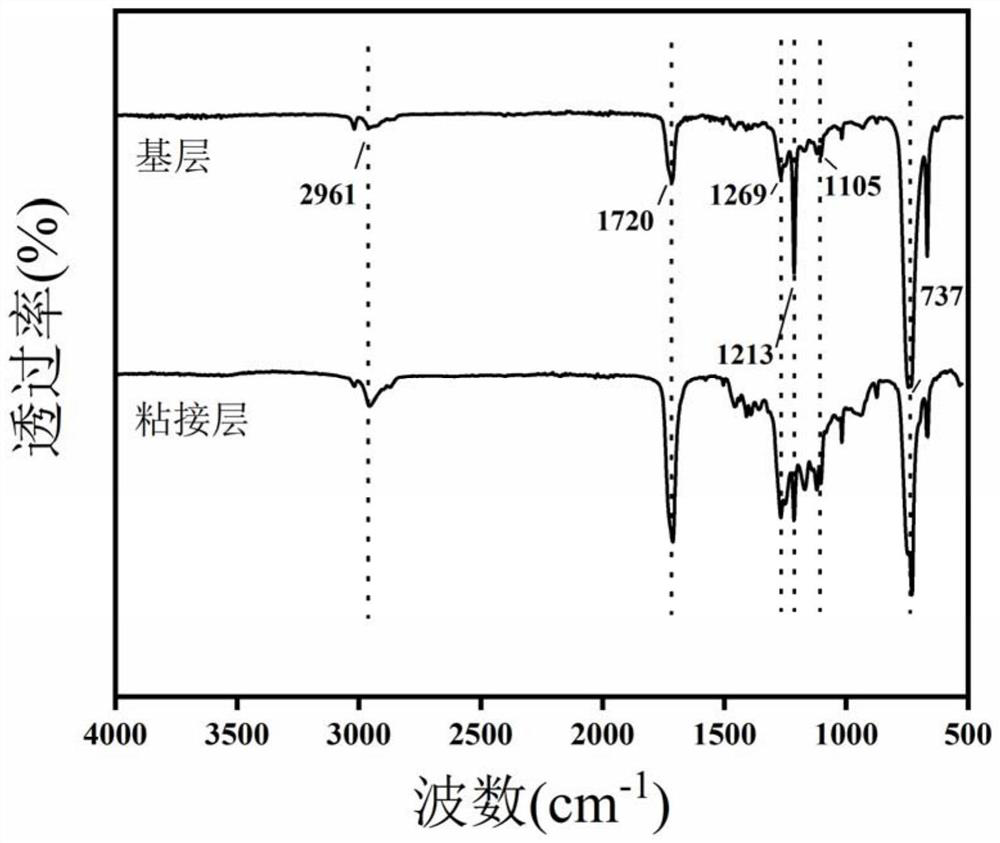

Method used

Image

Examples

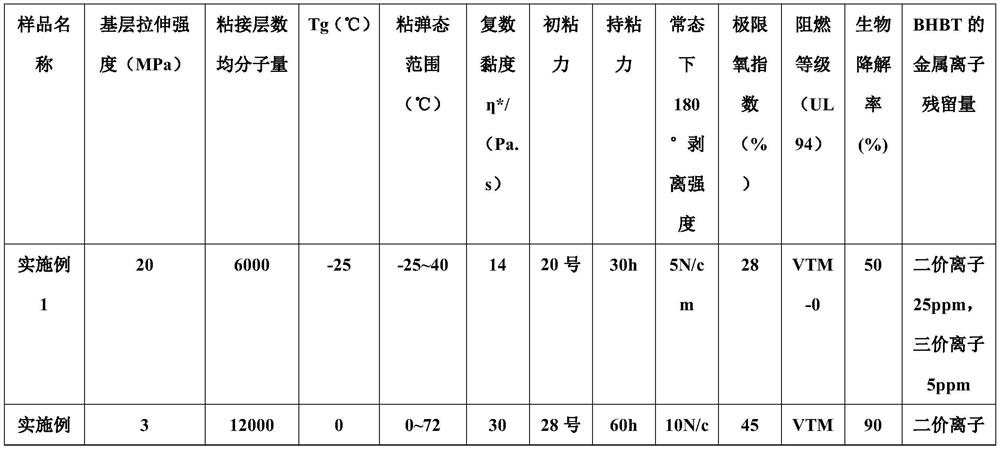

Embodiment 1

[0096] A preparation method of flame retardant degradable adhesive tape, the concrete steps are as follows:

[0097] (1) Treatment of discarded PBT

[0098] Pulverize the recycled waste PBT materials to obtain PBT powder with a particle size of less than 2 mm, which is then sieved and placed in a vacuum oven at 100 °C for drying for 12 hours;

[0099] (2) Preparation of regenerated BHBT

[0100] Take PBT powder, 1,4-butanediol, zinc acetate, triphenyl phosphate, sodium acetate and add it to the reaction kettle, pass nitrogen protection, dissolve at 180 ° C, and gradually heat up to 200 ° C after the system is clarified, keep This temperature was reacted for 1.5h; the water output was recorded, when it reached 90% of the theoretical value, vacuum was applied, the vacuum degree of the control system was 1000Pa, and the control time was 20min; then sodium phytate was added, and after the reaction for 15min, the unreacted substances were filtered while hot to obtain regeneration ...

Embodiment 2

[0115] A preparation method of flame retardant degradable adhesive tape, the concrete steps are as follows:

[0116] (1) Treatment of discarded PBT

[0117] Pulverize the recycled waste PBT materials to obtain PBT powder with a particle size of less than 2 mm, which is then sieved and placed in a vacuum oven at 130°C for drying for 8 hours;

[0118] (2) Preparation of regenerated BHBT

[0119] Take PBT powder, 1,4-butanediol, zinc acetate, triphenyl phosphate, and sodium acetate, add them to the reaction kettle, pass nitrogen protection, dissolve at 210 ° C, and gradually heat up to 240 ° C after the system is clarified, keep The temperature was reacted for 2.5h; the water output was recorded, when it reached 90% of the theoretical value, vacuum was applied, the vacuum degree of the control system was 200Pa, and the control time was 60min; then sodium phytate was added, and after the reaction for 15min, the unreacted substances were filtered while hot to obtain regeneration ...

Embodiment 3

[0132] A preparation method of flame retardant degradable adhesive tape, the concrete steps are as follows:

[0133] (1) Treatment of discarded PBT

[0134] Pulverize the recycled waste PBT materials to obtain PBT powder with a particle size of less than 2 mm, which is then sieved and placed in a vacuum oven at 100°C for drying for 8 hours;

[0135] (2) Preparation of regenerated BHBT

[0136] Take PBT powder, 1,4-butanediol, zinc acetate, triphenyl phosphate, and sodium acetate, add them to the reaction kettle, pass nitrogen protection, dissolve at 180 ° C, and gradually heat up to 240 ° C after the system is clarified, keep This temperature is reacted for 1.5h; the water output is recorded, when it reaches 90% of the theoretical value, vacuum is applied, the vacuum degree of the control system is 200Pa, and the control time is 20min; then sodium phytate is added, and after the reaction for 15min, the unreacted substances are filtered while hot to obtain regeneration BHBT; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com