Active turquoise blue dye used in digital printing, and preparation method thereof

A technology of reactive turquoise blue and dyes, applied in dyeing methods, organic dyes, applications, etc., can solve problems such as special structures, achieve low separation costs, high separation efficiency, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Low concentration separation experiment

[0039] Using reactive turquoise blue K-GL crude dye as raw material, first prepare 40g / L reactive turquoise blue K-GL dye aqueous solution, and remove particulate impurities through 0.5um ceramic microfiltration membrane. Microfiltration membrane area is 0.12m 2, , under the condition of 0.2 MPa, the average permeation flux of the microfiltration membrane is 138kg / (m 2. h). The pretreated dye was analyzed, the conductivity was 12.85ms / cm, and the chloride ion potential was 51.3mv.

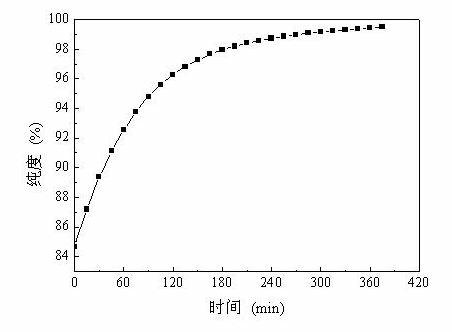

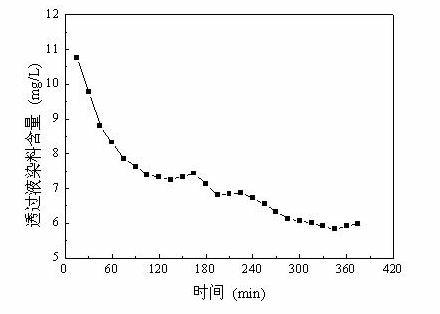

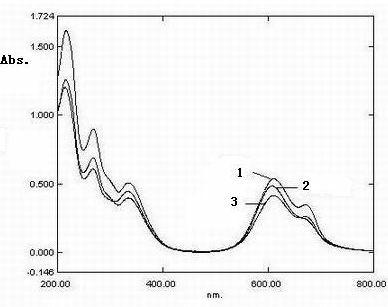

[0040] Take the pretreated reactive turquoise blue K-GL dye aqueous solution, and use a charged mosaic membrane (for the preparation of the charged mosaic membrane, refer to the report of CN2009100644084) to perform constant volume membrane filtration and desalination. The membrane area in the experiment is 8.0 m 2 , the operating condition is that the pressure range is 1.0MPa, and the operating temperature is controlled below 40...

Embodiment 2

[0045] Example 2 High-concentration separation experiment

[0046] With reactive turquoise blue K-GL crude dye as raw material, first prepare 80g / L reactive turquoise blue K-GL dye aqueous solution. The characteristic of embodiment 2 is to adopt the dyestuff of high concentration to carry out experiment, in order to judge the influence of raw material concentration. Its separation method and steps are the same as in Example 1.

[0047] Microfiltration experiment: The experimental results show that the permeation flux of the microfiltration membrane decreases at high concentrations, so the experiment adopts the method of increasing the operating pressure to maintain the permeation flux of the microfiltration. When the microfiltration operating pressure is 0.25 MPa, the average permeation flux of the microfiltration membrane is 135.6kg / (m 2. h), close to Example 1.

[0048] Constant volume purification experiment: the operating condition of the experiment is a pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com