System for treating dye wastewater and method for treating triphenylmethane dye wastewater

A technology for triphenylmethane and dye wastewater, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high cost and large energy consumption, and achieve fast reaction speed. , Increase the reaction rate constant, and improve the effect of substandard effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

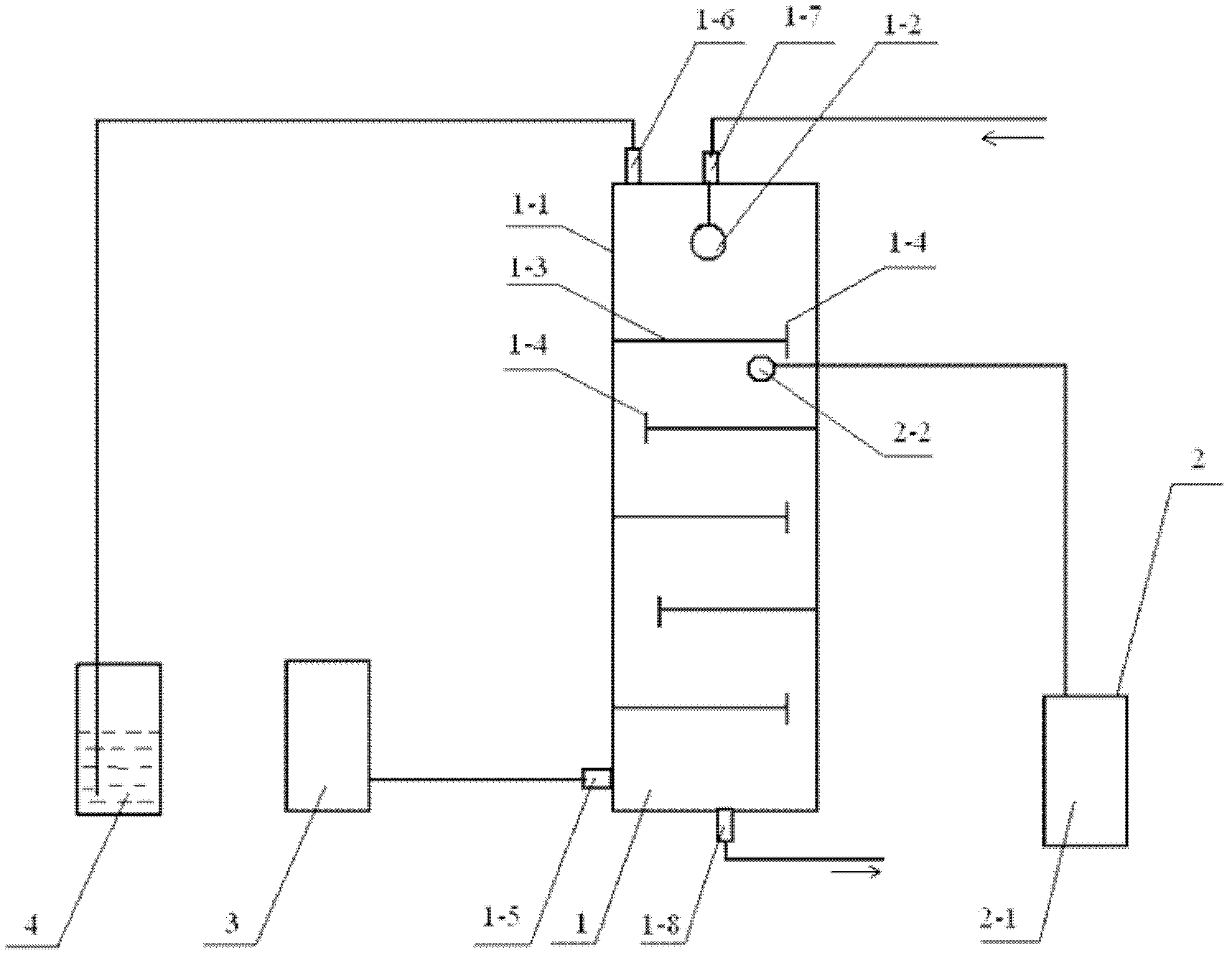

[0011] Specific implementation mode one: (please refer to the attached figure 1 ) A system for treating dye wastewater in this embodiment is composed of a sieve plate tower 1, an ultrasonic system 2, an ozone generator 3 and an ozone tail gas treatment device 4; -2, composed of sieve plate 1-3, overflow weir 1-4, air inlet 1-5, air outlet 1-6, water inlet 1-7 and water outlet 1-8, the diameter and height of sieve plate tower 1 The ratio is 1:5-10, the number of sieve plates 1-3 is 5-10, the water inlet 1-7 is connected with the water inlet distributor 1-2; the ultrasonic system 2 is composed of an ultrasonic generator 2-1 and a The ultrasonic probe 2-2 connected by the ultrasonic generating device 2-1 is composed of; The air inlets 1-5 are connected, and the gas outlets 1-6 of the sieve plate tower 1 are connected with the ozone tail gas treatment device 4 .

[0012] A system for treating dye wastewater in this embodiment utilizes a sieve tray tower combined with ultrasound ...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the ratio of the diameter to the height of the sieve tray column 1 is 1:6-8. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the number of sieve trays 1-3 of the sieve tray column 1 is 6-8. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com