Special binder for waterbrone inorganic zinc-rich anti-corrosion coating

A technology of inorganic zinc-rich, anti-corrosion coatings, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve problems such as inconsistent electrical properties, gelation, demulsification or delamination, and inconvenient production of binders , to achieve the effect of broadening the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

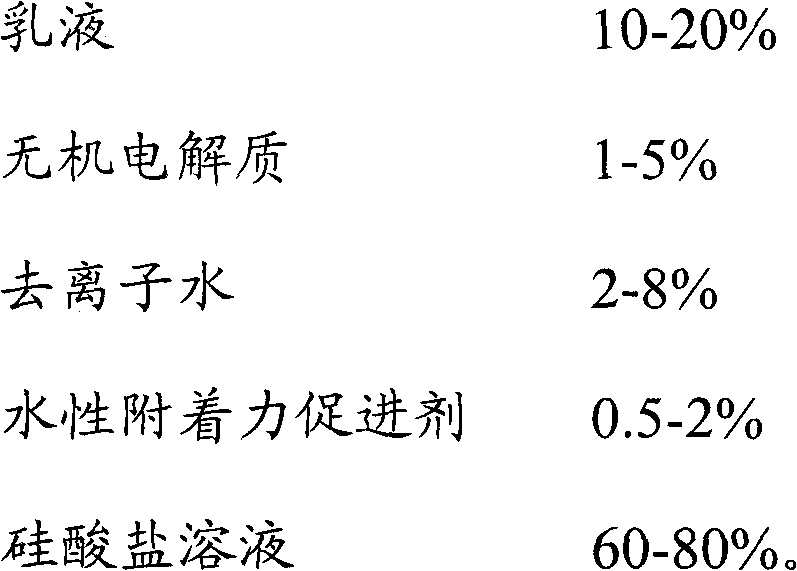

[0040] Prepare materials according to the following composition:

[0041]

[0042] Dissolve sodium hexametaphosphate in deionized water, slowly pour it into the silicon-acrylic emulsion under stirring, continue stirring for 30 minutes, add potassium silicate solution with a modulus of 6, and stir for 60 minutes to obtain the special adhesive for water-based inorganic zinc-rich anticorrosive coatings. Binder.

Embodiment 2

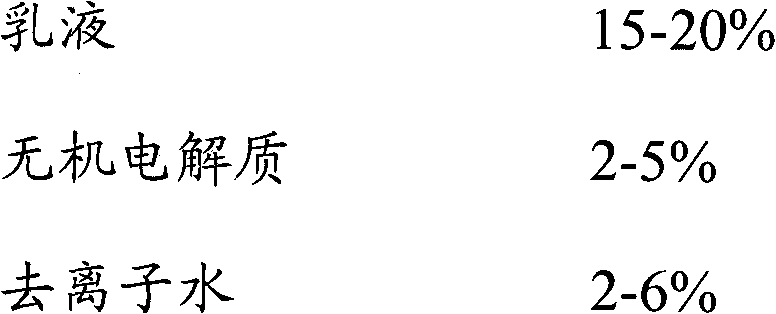

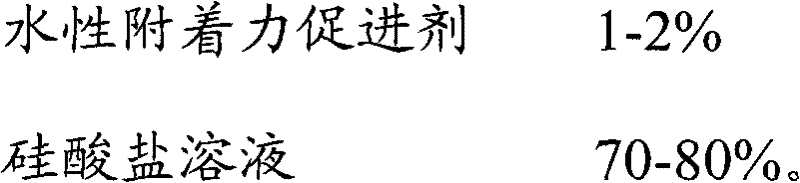

[0044] Prepare materials according to the following composition:

[0045]

[0046]Add potassium hydroxide to deionized water to dissolve, slowly pour it into pure acrylic emulsion under stirring, continue stirring for 25 minutes, add potassium silicate solution with a modulus of 5, and stir for 80 minutes to obtain water-based inorganic zinc-rich anti-corrosion coating special adhesive agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com