Crank shaft type electromagnetic switching mechanism

A technology for electromagnetic switches and crankshafts, applied in the direction of non-polar relays, etc., can solve the problems of low maintenance power, large swinging gap of moving contacts, low noise, etc., and achieve easy guarantee of pressure and spacing, small swinging gap, and small contact wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

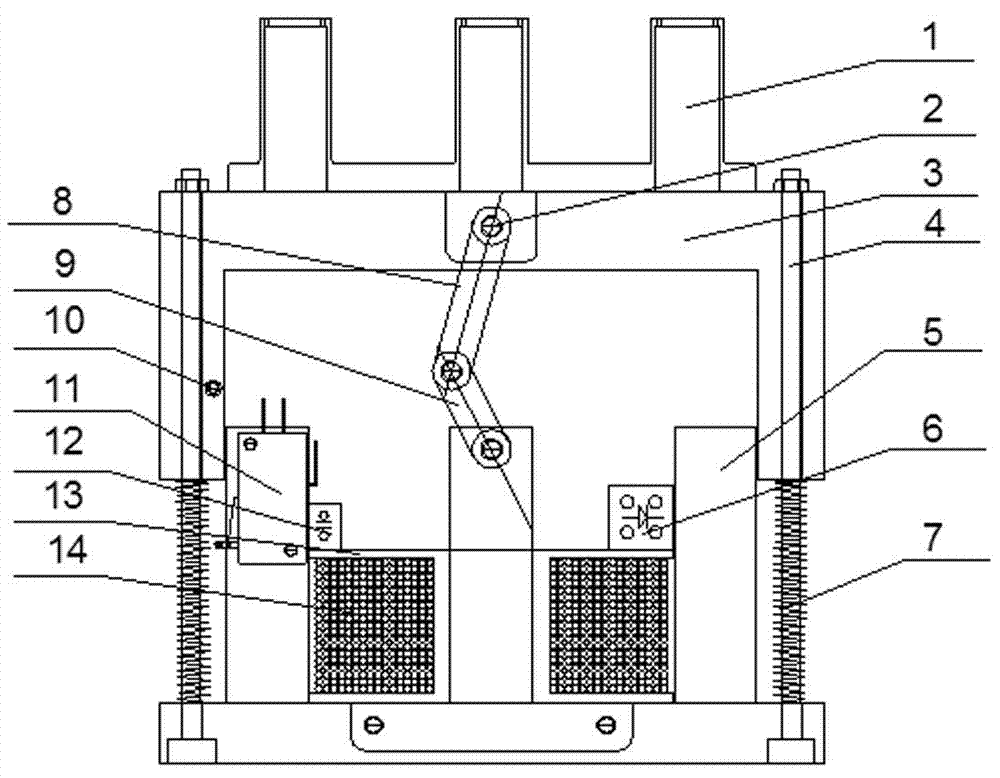

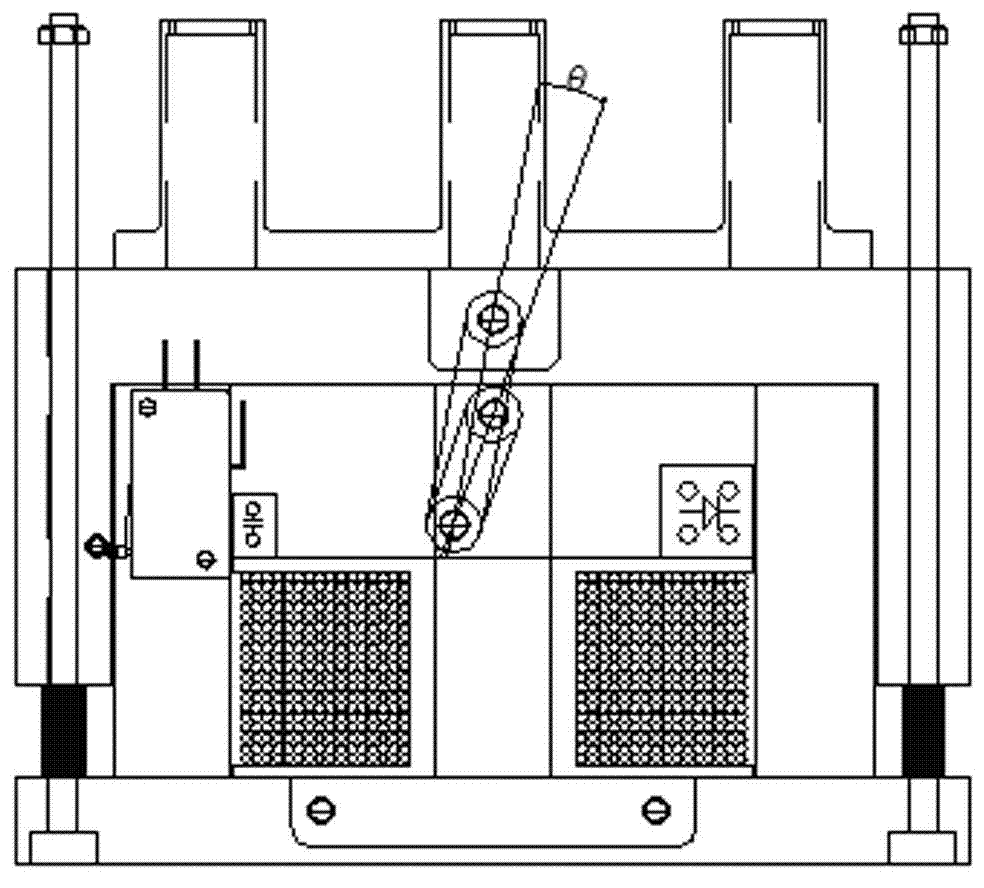

[0020] See figure 1 — Picture 10 :

[0021] The invention consists of a movable contact bracket 1, a positioning rod 2, a movable iron core 3, a guide rod 4, an iron core 5, a rectifier bridge 6, a spring 7, a connecting rod 8, a crankshaft 9, a touch rod 10, a travel switch 11, and a capacitor 12. , The skeleton 13 and the coil 14, wherein the coil 14 is wound in the skeleton 13, the rectifier bridge 6, the capacitor 12 are installed on the skeleton 13, the skeleton 13 is installed in the middle of the iron core 5, and the two lead wires of the coil 14 are connected to the rectifier bridge 6. On the DC output end, there are two guide rods 4 and two springs 7, the two guide rods 4 are respectively installed on the bases on both sides of the iron core 5, and the two springs 7 are respectively sleeved in the guide rods 4. The touch rod 10 is installed on one side of the moving iron core 3, the travel switch 11 is installed on one side of the iron core 5, the positioning rod 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com