Submerged membrane filtration system and process for removing suspended solid from phosphating liquid

A submerged membrane and filtration system technology, applied in metal material coating technology, ultrafiltration, etc., can solve the problems of ash on the surface of the plated parts, unfavorable recycling of phosphating residues, etc., and achieve high automation, low operating pressure, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

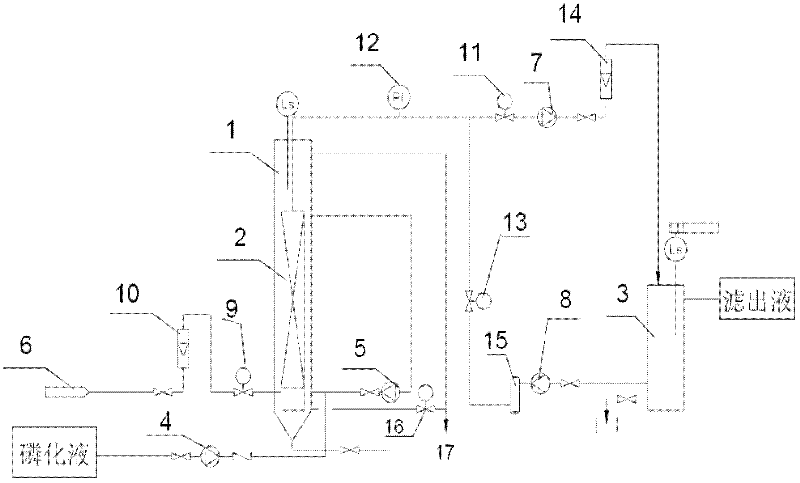

[0036] A submerged membrane filtration system for removing suspended solids in phosphating solution, such as figure 1 As shown, it includes membrane tank 1, membrane module 2, backwash tank 3, liquid inlet pump 4, circulation pump 5, blower 6, self-priming pump 7, backwash pump 8 and programmable controller. Membrane tank 1 is a sharp bottom The open container, the membrane module 2 is a submerged hollow fiber membrane module, the membrane module 2 is fixed in the membrane pool 1, the backwash tank 3 is a closed container, the liquid inlet pump 4 is connected to the lower part of the membrane pool 1 through a pipeline, and the circulation pump 5 passes through The pipes are respectively connected to the lower and upper parts of the membrane pool 1 and constitute the circulation pipeline of the membrane pool 1 itself. The electromagnetic pneumatic ball valve a 16 is installed on the circulation pipeline, and the blower 6 is connected to the bottom of the membrane pool 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com