On-line surface modification method of papermaking filling material

A technology of papermaking filler and surface modification, which is applied in papermaking, textile and papermaking, pulp raw material addition process, etc., can solve the problems of difficult to achieve commercial large-scale application, complex surface modification filler process, and unstable quality. Improved mechanical and optical properties, low cost, improved and effect of internal bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

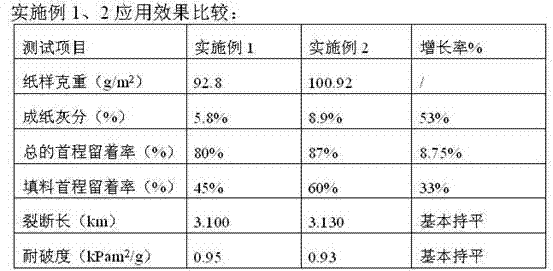

[0034] This example is a single-layer paperboard papermaking process under typical laboratory conditions.

[0035] Prepare :

[0036] The unbleached softwood pulp and the waste containerboard pulp were thawed together at a ratio of 20:80 to prepare a mixed pulp with a concentration of 1%, and the beating degree of the pulp was 50 degrees. The filler is heavy calcium carbonate (GCC), the filler mesh is 200 mesh, the degree of substitution of cationic starch is DS: 0.020, the retention aid is cationic polyacrylamide, the cationic molar ratio is 15%, and the molecular weight is 8 million.

[0037] Steps :

[0038] Turn on the agitator of the laboratory pulping tank, the stirring speed is 60 rpm, and then add 314 grams of clear water, 3.14 grams of mixed pulp, 0.03 grams of cationic starch, 0.47 grams of filler, 50 ppm cationic polyacrylamide and the like. After stirring evenly, the prepared slurry is copied and formed in a laboratory handsheet forming machine, and the relev...

Embodiment 2

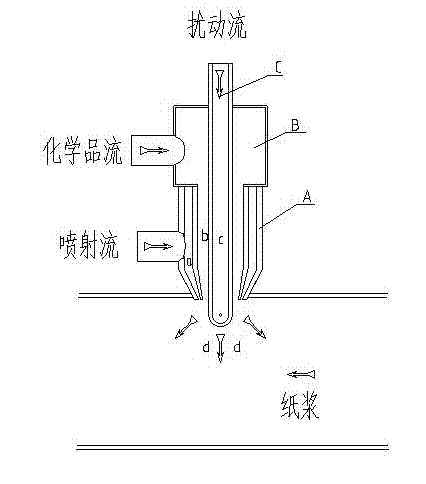

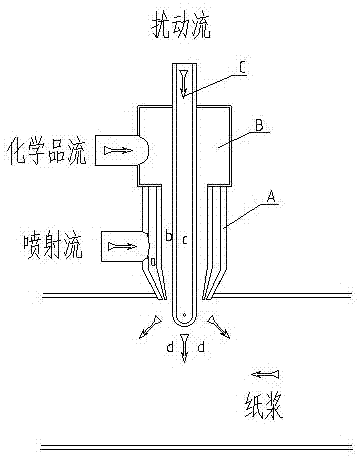

[0041] This example is a papermaking process using a jet mixing device to make pulp and make a single-ply board under laboratory conditions.

[0042] Prepare :

[0043] With embodiment 1.

[0044] Steps :

[0045] Open the laboratory jet mixing device, add 314 kg of clear water and 3.14 kg of mixed pulp, then adjust the jet flow velocity to 18 m / s, and adjust the disturbance flow velocity to 3 m / s. Then add 31.4 grams of cationic starch, 471 grams of filler, and 50 ppm cationic polyacrylamide etc. simultaneously by jet mixing device. After the jet mixing is completed, take out the wet pulp with the same absolute dry weight as in Example 1 from the prepared pulp, and copy it in a laboratory handsheet forming machine, and test the paper sample after pressing, dehydrating, drying, balancing and other steps related physical indicators.

[0046] In the laboratory dynamic water filter, the above-mentioned prepared slurry is dynamically filtered, and the total first-pass rete...

Embodiment 3

[0050] This example is the double-adhesive papermaking process under typical laboratory conditions.

[0051] Prepare :

[0052] Bleached softwood pulp, bleached hardwood pulp and bleached wheat straw pulp were jointly deflaked at a ratio of 20:30:50 to prepare mixed pulp with a concentration of 1%, and the pulp beating degree was 40 degrees. The filler is made of heavy calcium carbonate (GCC), the mesh number of the filler is 200 mesh, the cationic starch is gelatinized by the full gelatinization method, the cationic substitution degree DS: 0.030, the retention aid is made of cationic polyacrylamide, the cationic molar ratio is 15%, the molecular weight 800w.

[0053] Steps :

[0054] Turn on the agitator of the laboratory mixing tank, the stirring speed is 60 rpm, and then add 200 g of clear water, 2.20 g of mixed pulp, 0.02 g of cationic starch, 0.44 g of filler, 50 ppm of cationic polyacrylamide, etc. in sequence. After stirring evenly, the prepared slurry is copied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com