Mining photoelectric composite cable

A technology for optoelectronic composite cables and mines, which is applied in the field of cables to achieve the effects of saving pipeline space, convenient construction and excellent fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

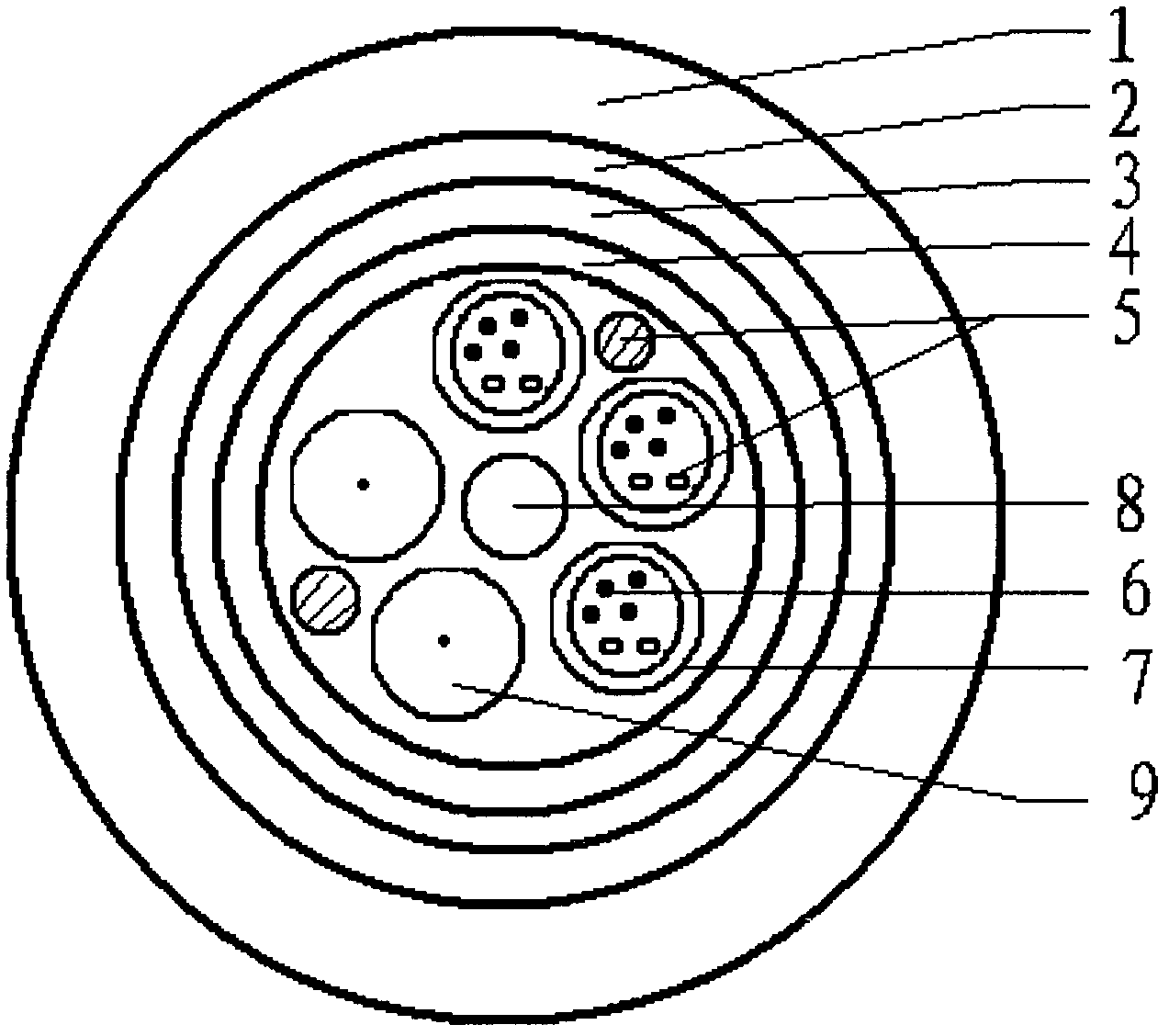

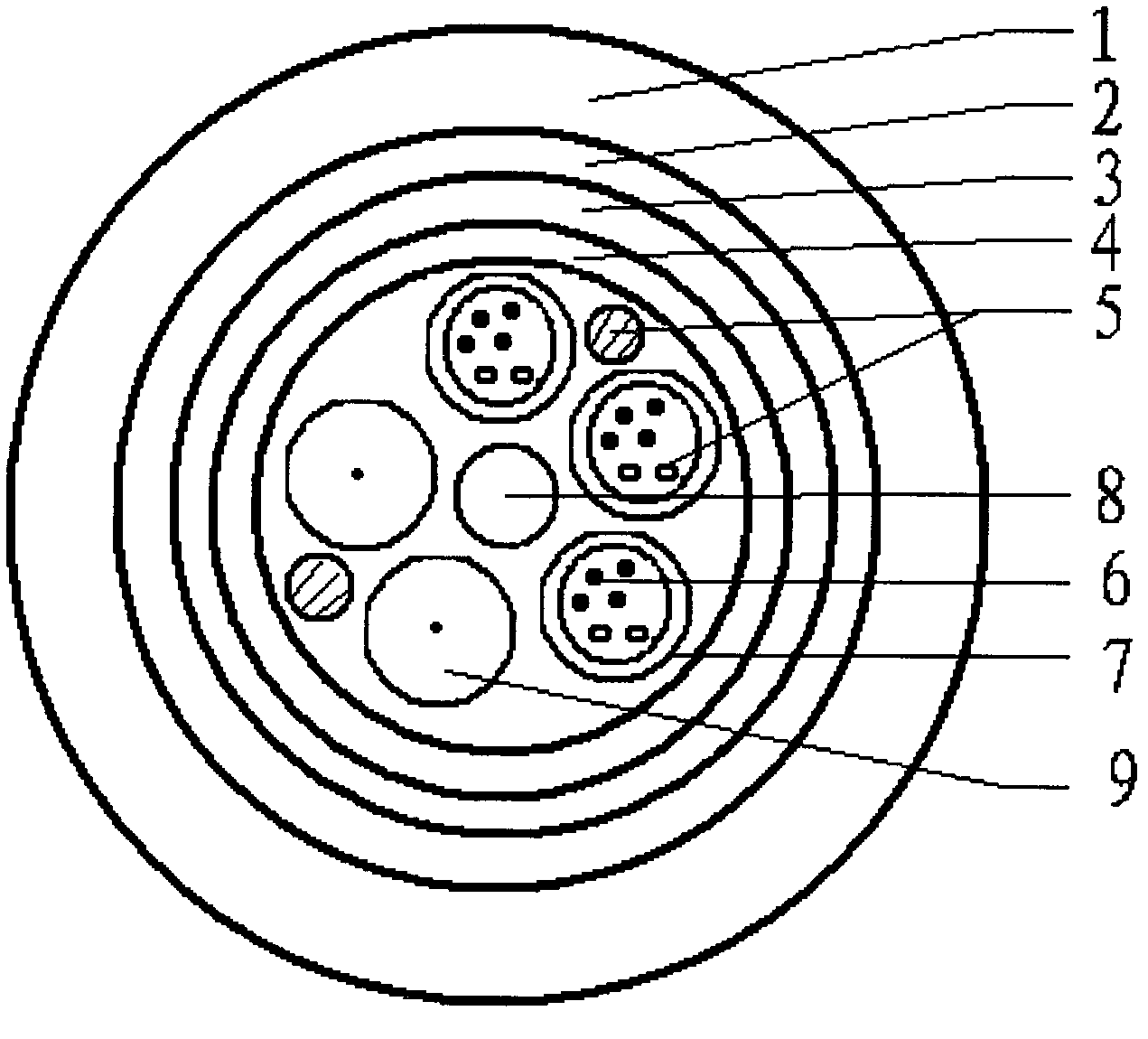

[0012] Such as figure 1 As shown, the photoelectric composite cable for mining mainly includes optical cable, low-voltage cable, central strength member 8, water-blocking yarn 5, water-blocking tape 4, mica tape 3, sheath 2 and sheath 1; Water blocking tape 4, mica tape 3, sheath 2 and sheath 1 are covered.

[0013] The optical cable adopts a fully dry structure, including optical fiber 6, water-blocking yarn 5, and loose tube 7, wherein the water-blocking yarn 5 is directly wrapped around the bundle of optical fibers 6 and wrapped in the loose tube 7.

[0014] The material of the sheath 2 is glass fiber reinforced plastic.

[0015] The material of the sheath 1 is low-smoke halogen-free polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com