New processing method of biodegradable stent

A processing method and biological technology, applied in the processing field of biodegradable stents, can solve problems such as no obvious improvement in expansion and fracture, large elastic retraction of stents, and inability to significantly improve radial support force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation of the blank type 2 mentioned in the above-mentioned steps 1. can be selected from any of the following methods, but is not limited to the following methods:

[0055] The biodegradable material is first processed into a tube by extrusion or injection molding, and then the tube is cut into a hollowed-out stent blank by laser2;

[0056] Prepare the biodegradable material into silk, and then weave the silk into mesh stent blank form 2;

[0057] Preparing a biodegradable material solution into a thin film by a precipitation method, then winding the film into a filament, and then weaving the filament into a stent blank 2; or

[0058] The biodegradable material is directly injected into the scaffold blank 2 in the injection mold.

[0059] The geometric dimensions of the stent blank mentioned in the above step ① need to be strictly controlled to ensure that the geometric dimensions of the final stent can meet the requirements of outer diameter and wall thickne...

example 1

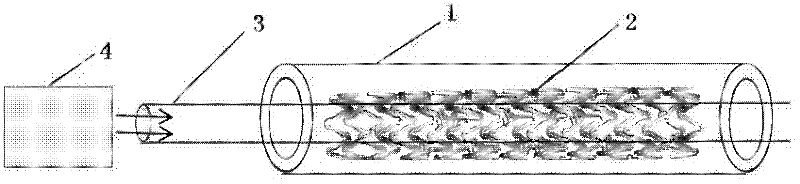

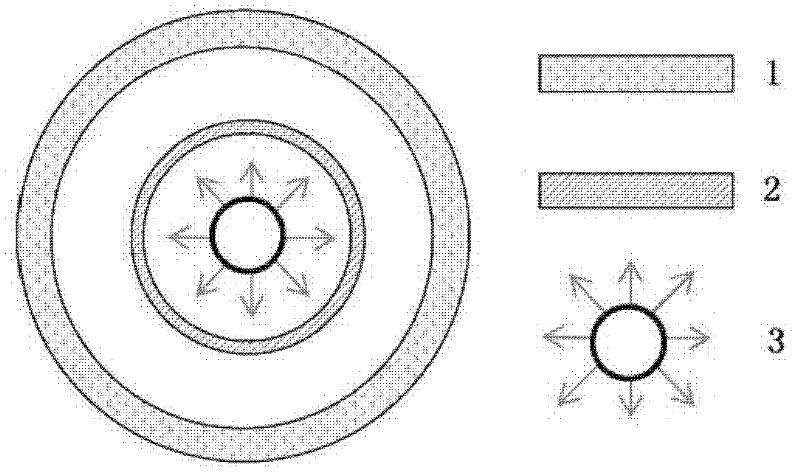

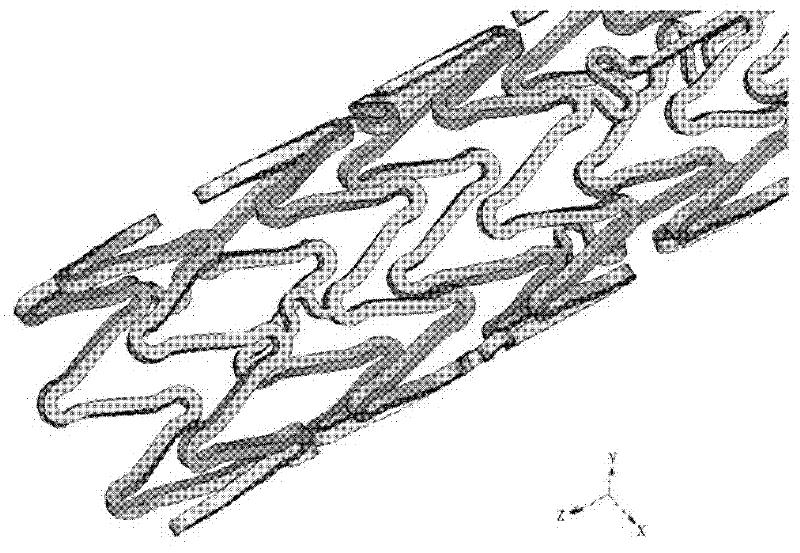

[0071] The material of the stent body selected in Example 1 is polylactic acid, a biodegradable polymer material. The polylactic acid is extruded into a pipe with an outer diameter of 2.0 mm and a wall thickness of 0.3 mm. The tube is cut into such as by laser cutting method image 3 In the stent blank 2 shown, the outer diameter of the stent blank 2 is 2.0 mm, and the wall thickness is 0.3 mm. Press and grip this stent blank 2 on an elastic tubing, such as polyamide tubing or polyether block amide tubing (the outer diameter of the elastic tubing is 1.0 mm), to form a stent blank 2 in a crimped state with an outer diameter of only 1.6 mm . Put the crimped stent blank 2 and elastic tubing into a stainless steel casing with an inner diameter of 3 mm, and the whole stent blank processing system is as follows: figure 1 shown. One end of the elastic tube is closed, and the other end of the elastic tube is connected to the filling device 4 through a high-pressure gas path, and t...

example 2

[0075] The material of the stent body selected in Example 2 is a biodegradable polymer material polylactic acid-glycolic acid copolymer. First, by injection molding, polylactic acid-glycolic acid copolymer is injection-molded into a mesh stent blank 2 with an outer diameter of 1.0 mm and a wall thickness of 0.2 mm. Put the stent blank 2 over an elastic tubing (such as latex tubing). Then, put the stent blank 2 and the latex tube into a stainless steel casing with an inner diameter of 2.5 mm, wherein one end of the latex tube is closed, and the other end of the latex tube is connected to the filling device 4 through a high-pressure air circuit. Then, the entire stent blank processing system (including the stent blank 2, the latex tube and the stainless steel casing) was heated to 40° C., and at the same time, the latex tube was filled with high-pressure air with a pressure of 400 Psi. Thus, while the latex tube is expanding, the stent blank 2 is expanded. The stent blank 2 ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com