Adhesion agent composition used in polarizer and polarizer utilizing the adhesion agent composition

A polarizing plate and adhesive technology, used in optics, adhesives, optical components, etc., can solve problems such as cracks, and achieve the effects of suppressing cracks, excellent bonding strength, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

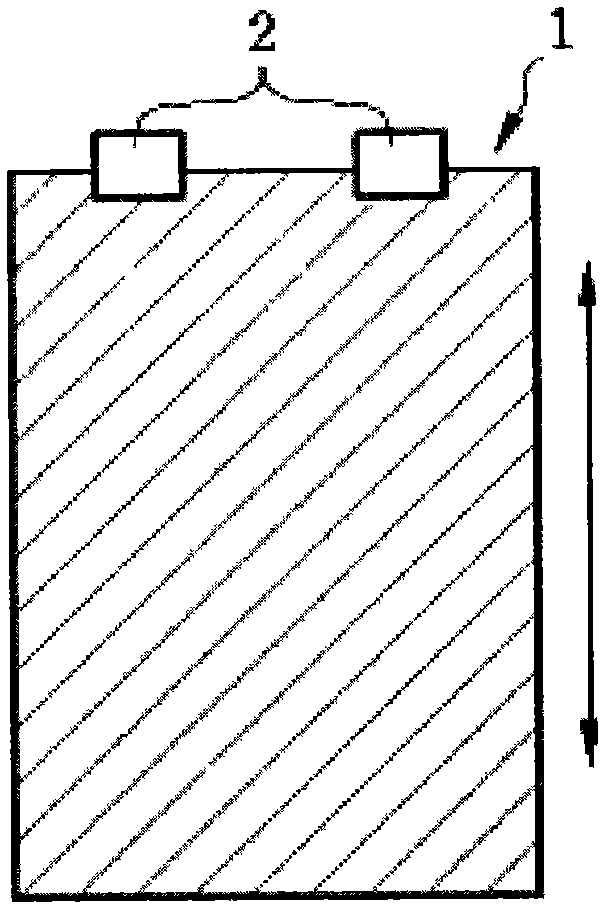

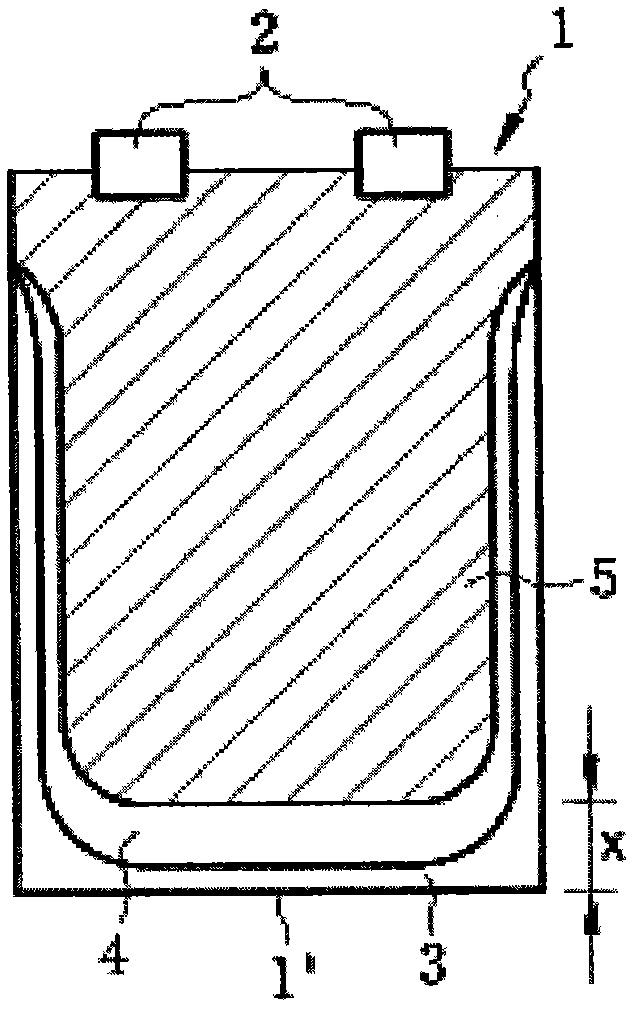

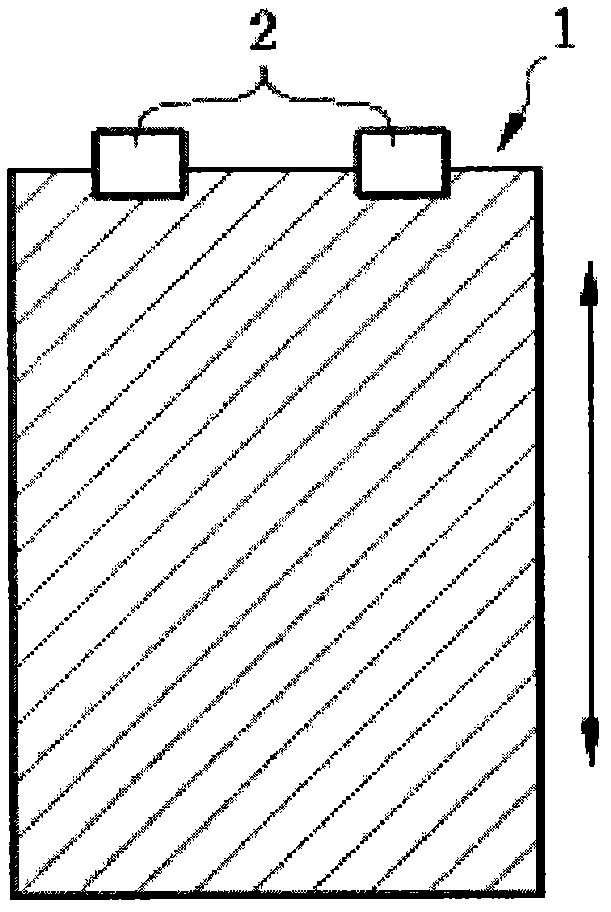

Image

Examples

Embodiment 1

[0065] (a) Production of polarizers

[0066] A polyvinyl alcohol film with an average degree of polymerization of about 2,400, a degree of saponification of 99.9 mol% or more, and a thickness of 75 μm was uniaxially stretched to about 5 times in a dry method, and the stretched state was maintained at 60° C. After being immersed in water for 1 minute, it was immersed in an aqueous solution having a weight ratio of iodine / potassium iodide / water at 28° C. of 0.05 / 5 / 100 for 60 seconds. Then, it was immersed in the aqueous solution whose weight ratio of 72 degreeC potassium iodide / boric acid / water was 8.5 / 8.5 / 100 for 300 second. Next, after washing with pure water at 26° C. for 20 seconds, it was dried at 65° C. to manufacture a polarizer in which iodine was adsorbed and aligned on a polyvinyl alcohol film.

[0067] (b) Manufacture of adhesive composition

[0068] Acetoacetyl-modified polyvinyl alcohol-based resin [trade name "Gohsenol Z200", Nippon Synthetic Chemical Industry Co...

Embodiment 2

[0072] In the step (b) of Example 1, the acetoacetyl-modified polyvinyl alcohol-based resin was diluted with a water / alcohol mixed solvent in such a manner that 3 parts were used for 100 parts of a water / alcohol mixed solvent, and An adhesive composition was produced in the same manner as in (b) of Example 1. The pH of this composition was 5.6, and the viscosity was 7.5 mPa·sec. A polarizing plate was fabricated in the same manner as in step (c) of Example 1 except for using this composition.

Embodiment 3

[0074] In the step (b) of Example 1, the acetoacetyl-modified polyvinyl alcohol-based resin was diluted with a water / alcohol mixed solvent in such a manner that 5 parts were used for 100 parts of the water / alcohol mixed solvent, and An adhesive composition was produced in the same manner as in (b) of Example 1. The composition had a pH of 5.6 and a viscosity of 17.0 mPa sec. A polarizing plate was fabricated in the same manner as in step (c) of Example 1 except for using this composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com