Nano-silver surface modified polyurethane central venous catheter and preparation method thereof

A central venous catheter, surface modification technology, applied in the direction of catheter, liquid chemical plating, metal material coating technology, etc., can solve the problems of variation, untreatable diseases, etc., and achieve long antibacterial validity period, strong antibacterial and anti-infection performance , good anti-infection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

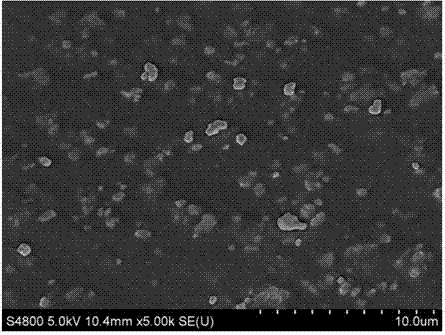

[0034] Soak a 15cm-long polyurethane central venous catheter in a mixed solvent of ethanol and deionized water with a volume ratio of 1:1 and ultrasonically clean it for 1 hour to remove the dirt on the surface of the catheter, take out the catheter, rinse it fully with deionized water, and put it in a vacuum After drying in the oven, weigh them.

[0035] Soak the dry polyurethane central venous catheter in 0.2mol / L AgNO 3 In aqueous solution (AgNO 3 directly dissolved in water), and irradiated at a distance of 10cm from the ultraviolet lamp for 20min, and finally the catheter was taken out, rinsed with a large amount of deionized water and soaked in water for 24h, during which the water was changed continuously, and vacuum-dried to constant weight.

[0036] The modified catheters with lengths of 15, 25, 35, and 45 mm were respectively taken for antibacterial ability test, and the obtained turbidities were 1.163, 0.533, 0.127, and 0.175 respectively; The turbidity of the ant...

Embodiment 2

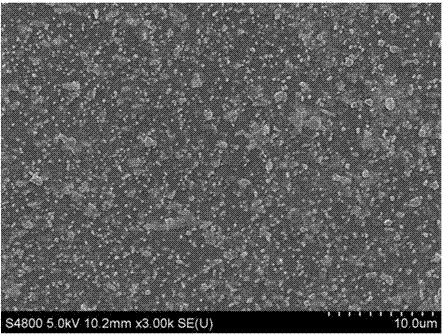

[0038] Soak a 15cm-long polyurethane central venous catheter in a mixed solvent of ethanol and deionized water with a volume ratio of 1:1 and ultrasonically clean it for 1 hour to remove the dirt on the surface of the catheter, take it out and rinse it fully with deionized water, and put it in a vacuum drying oven After drying, weigh them.

[0039] Soak the dry polyurethane central venous catheter in 0.2mol / L AgNO 3 ethanol solution (AgNO 3 Dissolve in absolute ethanol, add water less than 2% of the total volume of the solution to help dissolve the remaining insoluble part, and mix the two), and irradiate for 20 minutes at a distance of 10cm from the ultraviolet lamp, finally take out the catheter, and then use a large amount of deionized Rinse with water and soak in water for 24 hours, change the water constantly, and vacuum dry to constant weight.

[0040] The modified catheters with lengths of 15, 25, 35, and 45 mm were respectively taken for antibacterial ability test, a...

Embodiment 3

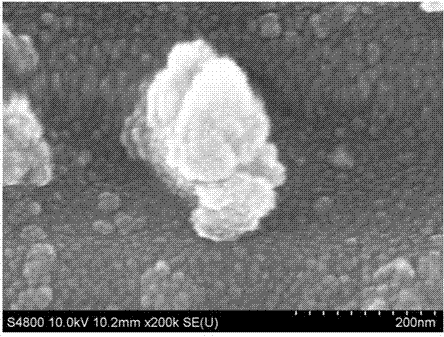

[0042] Soak a 15cm-long polyurethane central venous catheter in a mixed solvent of ethanol and deionized water with a volume ratio of 1:1 and ultrasonically clean it for 1 hour to remove the dirt on the surface of the catheter, take it out and rinse it fully with deionized water, and put it in a vacuum drying oven After drying, weigh them.

[0043] Soak the dry polyurethane central venous catheter in 0.2mol / L AgNO 3 Aqueous solution (AgNO 3 Dissolve directly in water) for 2 minutes, take it out, then irradiate it at a distance of 10cm from the ultraviolet lamp for 20 minutes, finally take out the catheter, rinse it with a large amount of deionized water and soak it in water for 24 hours, change the water continuously, and vacuum dry to constant weight.

[0044] The modified catheters with lengths of 15, 25, 35, and 45 mm were respectively taken for antibacterial ability test, and the turbidities obtained were 1.515, 0.730, 0.908, and 0.338 respectively; The same length order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com