Nano silver/cube silver chloride photo-catalytic material and preparation method

A catalytic material and cube technology, applied in the field of photocatalysis, can solve the problems of long preparation period, complex process, high temperature required for the reaction process, etc., and achieve the effects of short preparation period, low reaction temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

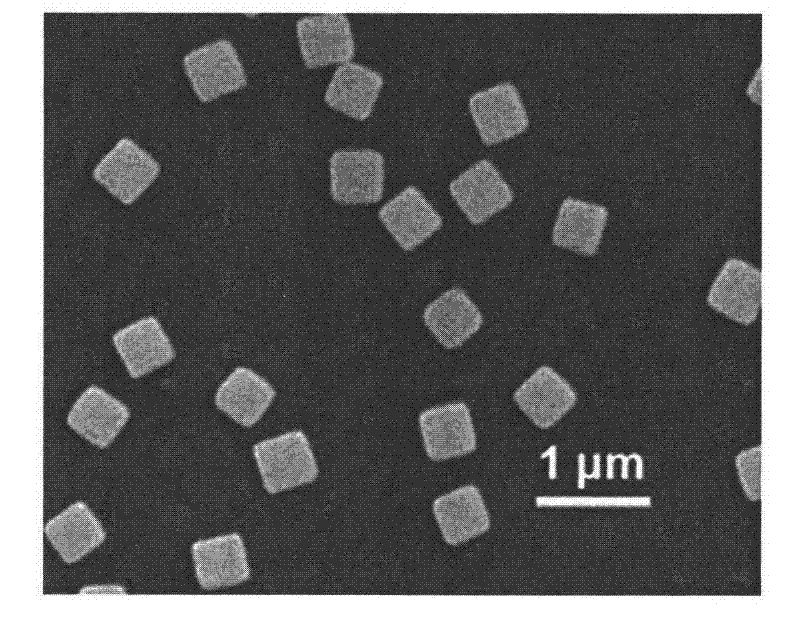

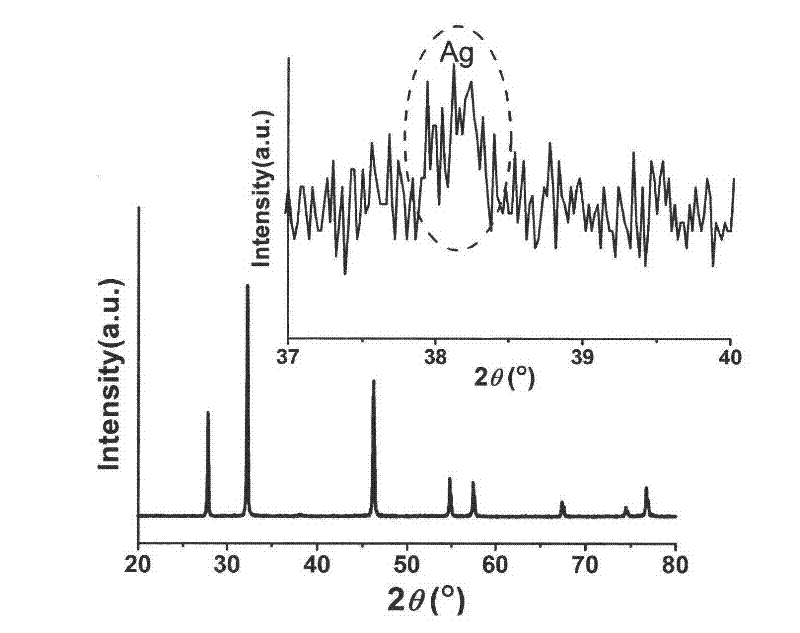

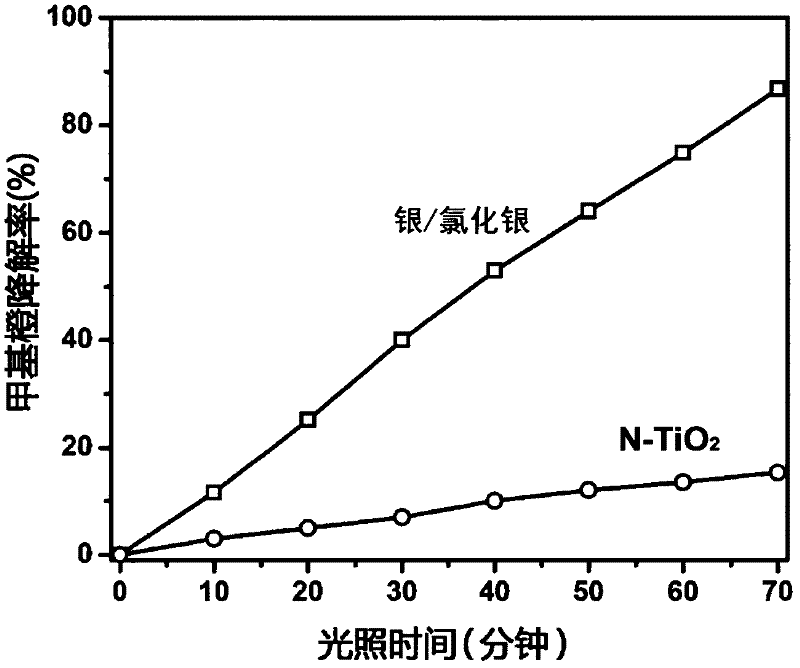

[0022] Under vigorous stirring, use a peristaltic pump to inject silver nitrate solution and sodium chloride solution into the reaction pot containing gelatin and sodium chloride aqueous solution at the same time, control the temperature of the reaction pot at 80°C, and control the injection of silver nitrate and sodium chloride solution Speed, so that the pCl value of the whole reaction process is constant at 1.4. After the injection of the silver nitrate solution and the sodium chloride solution, physical maturation was carried out at this temperature for 30 minutes. The prepared silver chloride microcrystals were centrifuged and washed 6 times with warm water at 45°C to remove the gelatin protective agent, excess sodium chloride and sodium nitrate produced by the reaction. Silver chloride microcrystals were dispersed in aqueous solution, methanol was added as a hole-scavenging agent, and a 300W high-pressure mercury lamp was used to perform photoreduction treatment on the s...

Embodiment 2

[0026] Under vigorous stirring, use a peristaltic pump to inject silver nitrate solution and sodium chloride solution into the reaction pot containing polyvinylpyrrolidone K30 and sodium chloride aqueous solution at the same time. The injection speed of the solution was such that the pCl value throughout the reaction process was constant at 1.4. After the injection of the silver nitrate solution and the sodium chloride solution, physical maturation was carried out at this temperature for 30 minutes. The prepared silver chloride microcrystals were centrifuged and washed 6 times with warm water at 45°C to remove the gelatin protective agent, excess sodium chloride and sodium nitrate produced by the reaction. Silver chloride microcrystals were dispersed in aqueous solution, methanol was added as a hole-scavenging agent, and a 300W high-pressure mercury lamp was used to perform photoreduction treatment on the silver chloride microcrystals for 2 hours to form silver nanoparticles o...

Embodiment 3

[0028] Under vigorous stirring, use a peristaltic pump to inject silver nitrate solution and sodium chloride solution into the reaction pot containing gelatin and sodium chloride aqueous solution at the same time, control the temperature of the reaction pot at 70 °C, and control the injection of silver nitrate and sodium chloride solution Speed, so that the pCl value of the whole reaction process is constant at 1.4. After the injection of the silver nitrate solution and the sodium chloride solution, physical maturation was carried out at this temperature for 30 minutes. The prepared silver chloride microcrystals were centrifuged and washed 6 times with warm water at 45°C to remove the gelatin protective agent, excess sodium chloride and sodium nitrate produced by the reaction. Silver chloride microcrystals were dispersed in aqueous solution, methanol was added as a hole-scavenging agent, and a 300W high-pressure mercury lamp was used to perform photoreduction treatment on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com