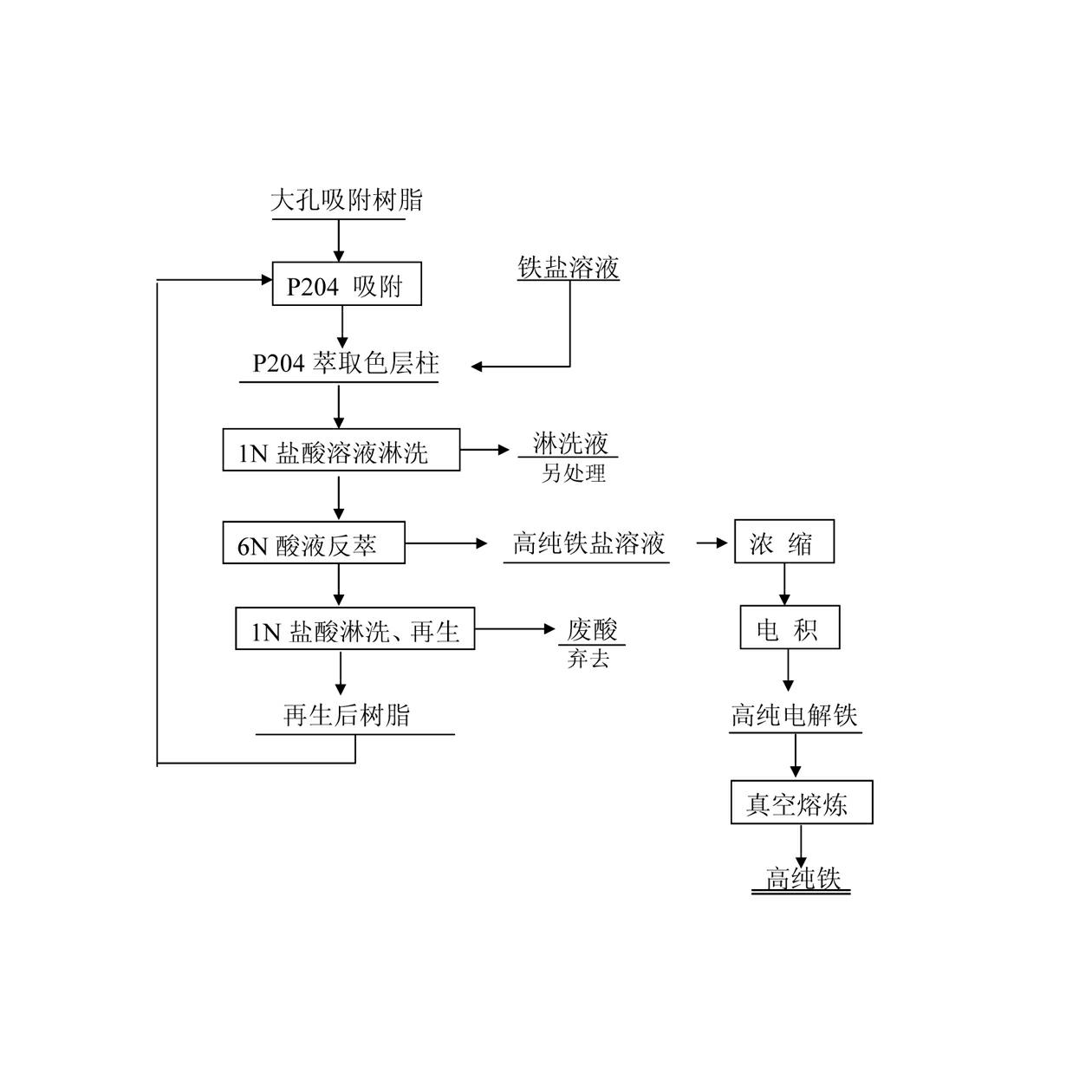

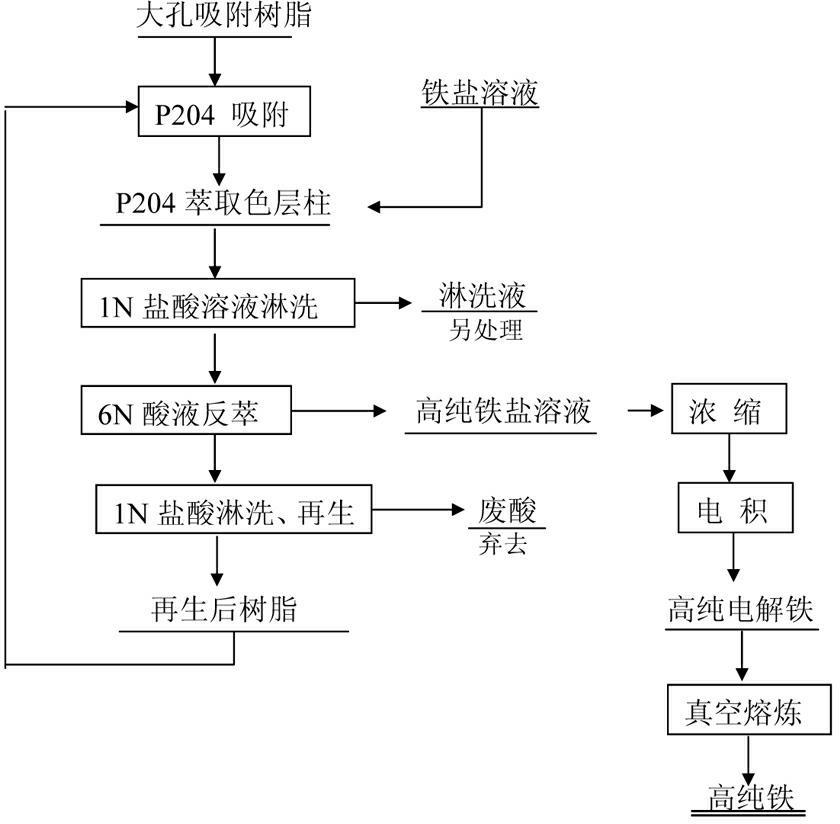

Method for purifying iron solution by adopting extraction chromatography

A technology for chromatographic separation and purification of iron, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problem of difficult to achieve deep separation of iron and these impurities, and achieve the reduction of irritating odor, easy equipment, and large equipment capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Use 10 kg of water-containing macroporous adsorption resin (purchased from the market, brand HPD-100), and its relevant parameters:

[0034] 1. Particle size: The particle size is 70~150 mesh (0.1-0.2mm) ≥ 90%.

[0035] 2. Average pore diameter: 85-90°A; specific surface 650-700m 2 / g; adsorption flow rate: 1-4BV / h; desorption flow rate: 0.6-2BV / h; desorbent: ethanol or ethanol aqueous solution; desorbent dosage: 2-3 BV.

[0036] The P204 extraction agent is adsorbed on the macroporous adsorption resin by saponification and adsorption. The specific operation is: put 10 kg of water-containing macroporous adsorption resin into water, add 2 kg of P204 extraction agent, and perform adsorption treatment under stirring conditions , after filtration, 34% P204 extraction resin was prepared, and the resin that absorbed the extractant was wet-packed into a column with a diameter of 80mm and a length of 850mm, and assembled into a P204 extraction resin column. The empty volume i...

Embodiment 2

[0042] Prepare 60% P204 extraction and leaching resin, test operation method is the same as embodiment 1. Add ferric sulfate feed liquid 5 liters, wherein iron concentration is 30 grams / liter, the acidity of feed liquid [H + ] was 1.0 mol / liter, and the P204 extraction resin column was rinsed until the iron concentration of the eluate was about 30 grams / liter, and the color of the chromatographic column changed from colorless to deep red at this moment.

[0043] with [H + ] is 1.0 mol / liter of hydrochloric acid solution as the eluent to wash the iron-loaded P204 extraction resin, and observe that the color of the chromatographic column changes from red to colorless, and the end of the washing is reached. At this time, the sulfuric acid solution with an acidity of 6 mol / L was used instead to quickly elute the iron ions adsorbed in the chromatographic column, and the color of the chromatographic column changed from colorless to red during the process.

[0044] Finally, regener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com