Amorphous state hydrogen absorption alloy having mechanical property and preparation method thereof

A technology of hydrogen-absorbing alloy and amorphous state, which is applied in the field of amorphous hydrogen-absorbing alloy with mechanical properties and its preparation, which can solve the problems of high-temperature environment, poor mechanical properties, and pulverization of porous materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

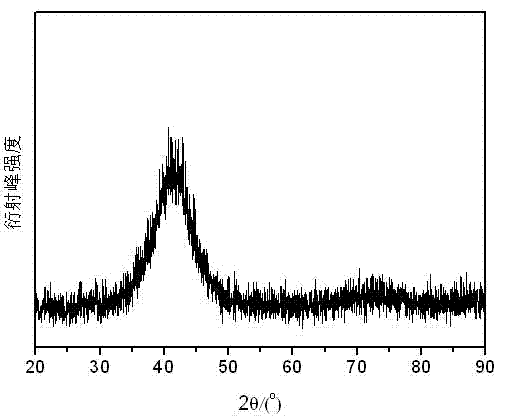

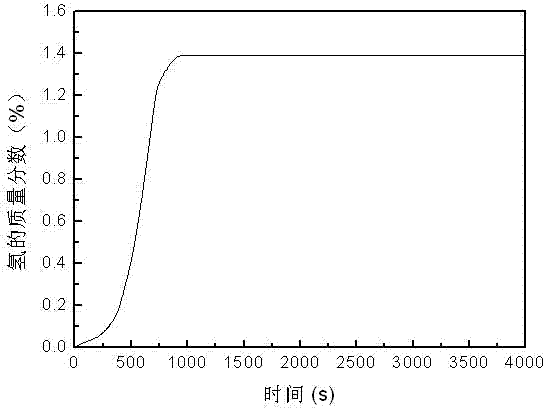

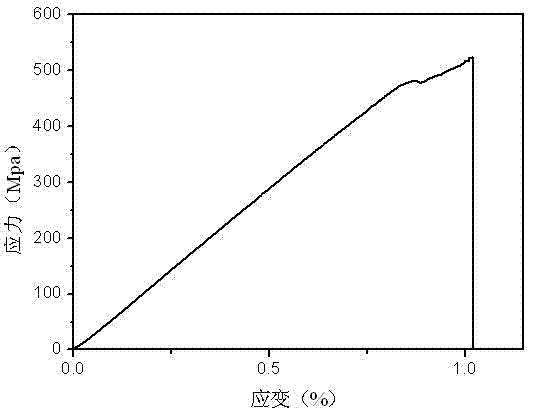

[0020] The general chemical formula of amorphous hydrogen-absorbing alloy is: (ZrTi) 0.5 (Ni 0.6 Cr 0.1 m x ) 2.3 Where: M = V, x = 0.1, constitute (ZrTi) 0.5 (Ni 0.6 Cr 0.1 V 0.1 ) 2.3 alloy, the specific steps are as follows:

[0021] A. Calculate the mass ratio of Zr, Ti, Ni, Cr, and V according to the chemical formula for batching. The mass percentage of raw materials is 99.99% for Zr, Ti, and Ni, 99.25% for Cr, and 99.94% for V.

[0022] B. Put the raw materials in a vacuum arc melting furnace, vacuumize to 3×10-3Pa, feed Ar (argon) gas to 0.05KPa, and then vacuumize to 3×10-3Pa -3 Pa, then fill it with Ar (argon) gas to atmospheric pressure, and smelt it 4 times to make the alloy mix evenly, and turn the ingot every time it is smelted. Obtained in crystalline state (ZrTi) 0.5 (Ni 0.6 Cr 0.1 V 0.1 ) 2.3 alloy ingot.

[0023] C. Put a small alloy block (about 6g) into a quartz tube with an outer diameter of 14mm and an inner diameter of 11mm with a small ho...

Embodiment 2

[0027] This embodiment is basically the same as Embodiment 1, the special feature lies in the general chemical formula of the amorphous hydrogen-absorbing alloy: (ZrTi) 0.5 (Ni 0.6 Cr 0.1 m x ) 2..3 Middle: M = V, x = 0.3, composition (ZrTi) 0.5 (Ni 0.6 Cr 0.1 V 0.3 ) 2.3 alloy, the specific steps are as follows:

[0028] A. Calculate the mass ratio of Zr, Ti, Ni, Cr, and V according to the chemical formula for batching. The mass percentage of raw materials is 99.99% for Zr, Ti, and Ni, 99.25% for Cr, and 99.94% for V.

[0029] B. Put the raw material in the vacuum arc melting furnace, and evacuate to 3×10 -3 Pa, pass Ar (argon) gas to 0.05KPa, then vacuumize to 3×10 -3 Pa, then fill it with Ar (argon) gas to atmospheric pressure, and smelt it 4 times to make the alloy mix evenly, and turn the ingot every time it is smelted. Obtained in crystalline state (ZrTi) 0.5 (Ni 0.6 Cr 0.1 V 0.3 ) 2.3 alloy ingot.

[0030] C. Put a small alloy block (about 6g) into a qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com