Infrared focal plane array device and manufacture method thereof

A technology of an infrared focal plane and a manufacturing method, which is applied in the field of infrared focal plane array devices and their manufacturing, can solve the problems of incompatibility of VOx materials, inability to dissipate infrared energy in time, and high device cost, so as to improve the quality of infrared imaging and increase the Thermal isolation effect, effect of improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

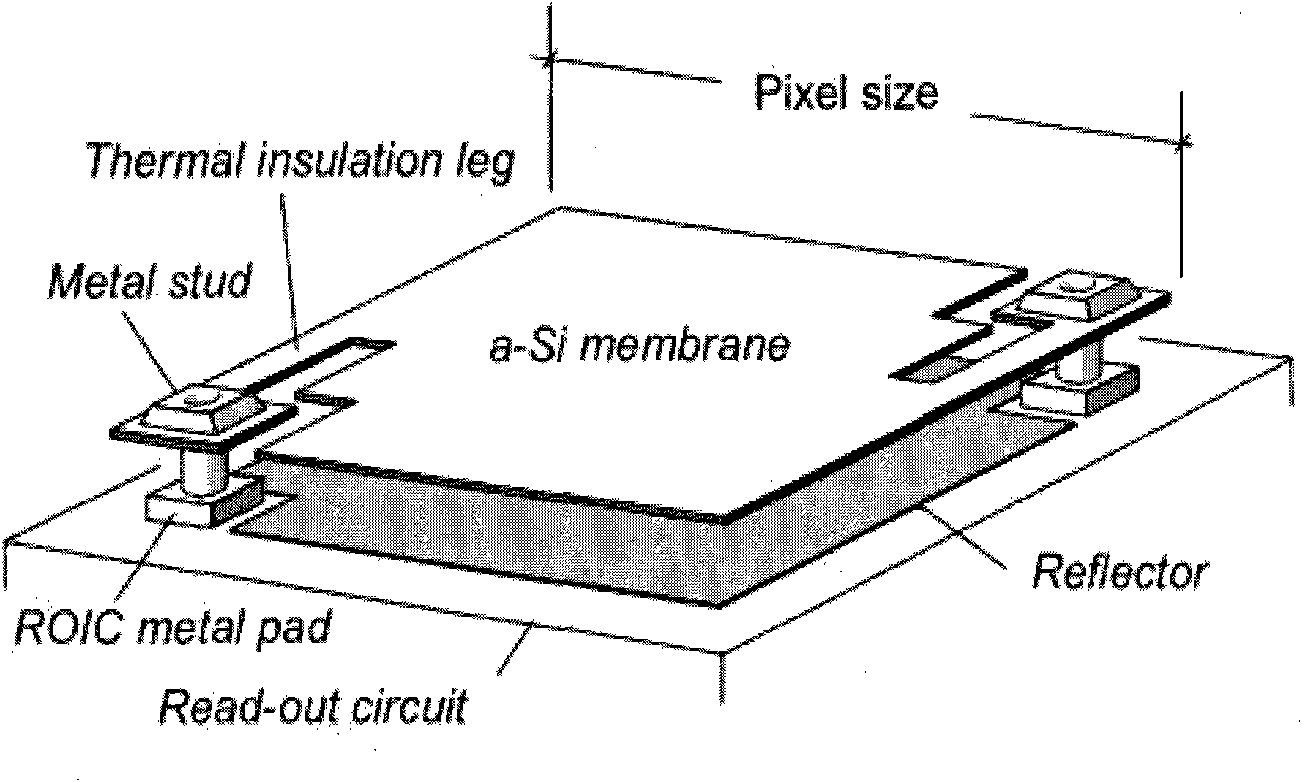

[0056] image 3 It is a schematic structural diagram of the infrared focal plane array device in this embodiment, Figure 4 for image 3 In order to clearly show the innovation of the present invention, only one detection unit of the infrared focal plane array is shown in the figure, and the detection unit includes:

[0057] Substrate 101;

[0058] a cavity 104 located in the substrate 101;

[0059] an infrared sensitive layer 105 suspended above the cavity 104;

[0060] A reflective layer 103, disposed at the bottom of the cavity 104, opposite to the infrared sensitive layer 105;

[0061] The cantilever beam 106 is suspended above the substrate 101 and is substantially at the same level as the infrared sensitive layer 105 , one end of which is fixedly connected to the substrate 101 , and the other end is fixedly connected to the infrared sensitive layer 105 .

[0062] Wherein, the substrate 101 is a bare wafer of single crystal silicon, and the cavity 104 is formed by etch...

Embodiment 2

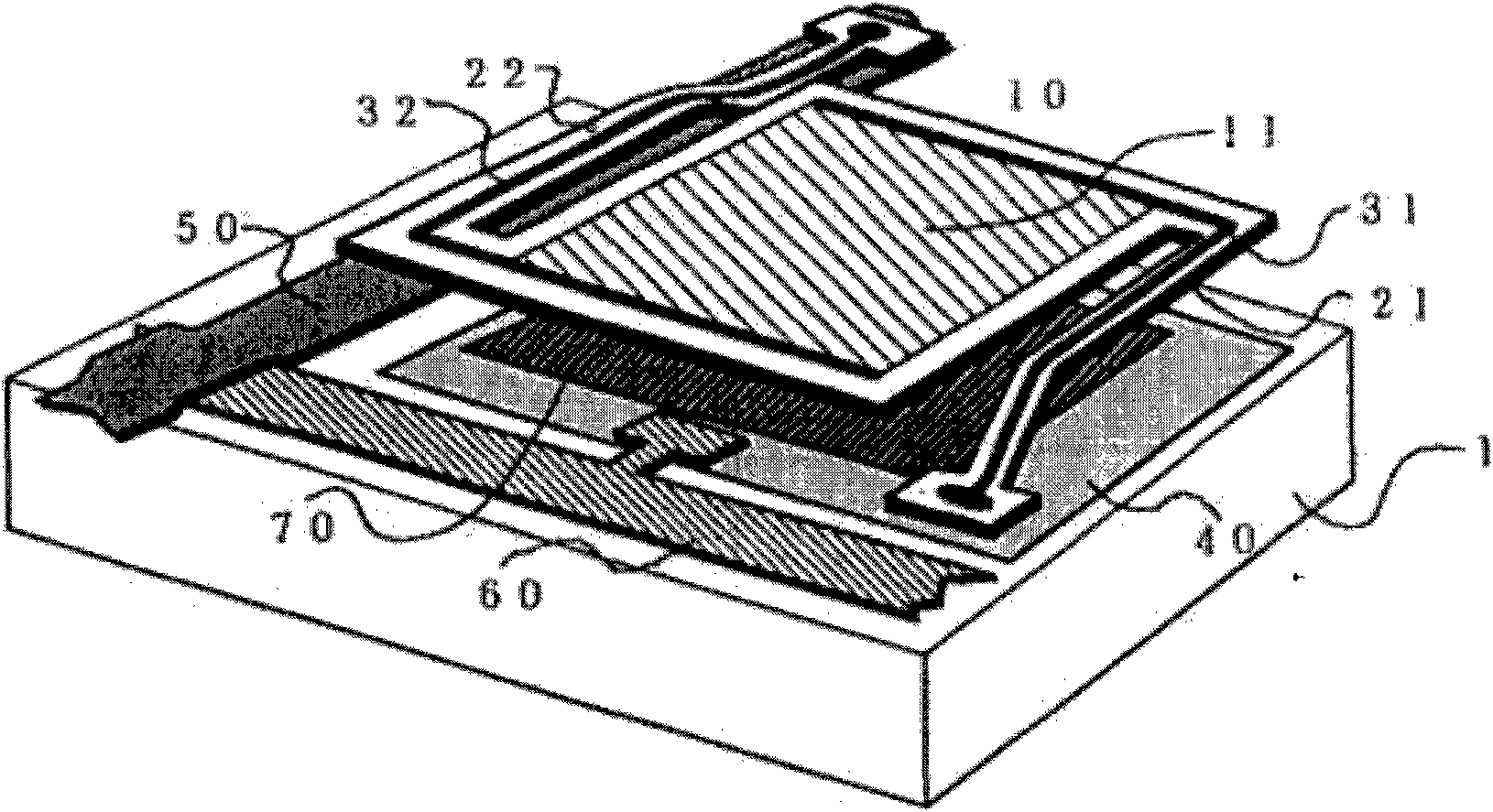

[0076] Figure 10 It is a schematic structural diagram of the infrared focal plane array device in this embodiment. Similarly, its detection unit also includes: a substrate 201, a cavity 204 located in the substrate 201, suspended above the cavity 204 The infrared sensitive layer 205 is arranged on the bottom of the cavity 204, opposite to the infrared sensitive layer 205, the reflective layer 203 is suspended on the cantilever beam 206 above the substrate 201, and one end of the cantilever beam is fixed to the heat sink 208 connected, and the other end is fixedly connected with the infrared sensitive layer 205.

[0077] The difference from the first embodiment is that the heat sink 208 is formed on the surface of the substrate, and the cavity 204 is surrounded by the heat sink 208 . In other words, the heat sink 208 is not integrated with the substrate 201 , but is a specially formed structure on the surface of the substrate, and the cavity 204 is not formed by etching the s...

Embodiment 3

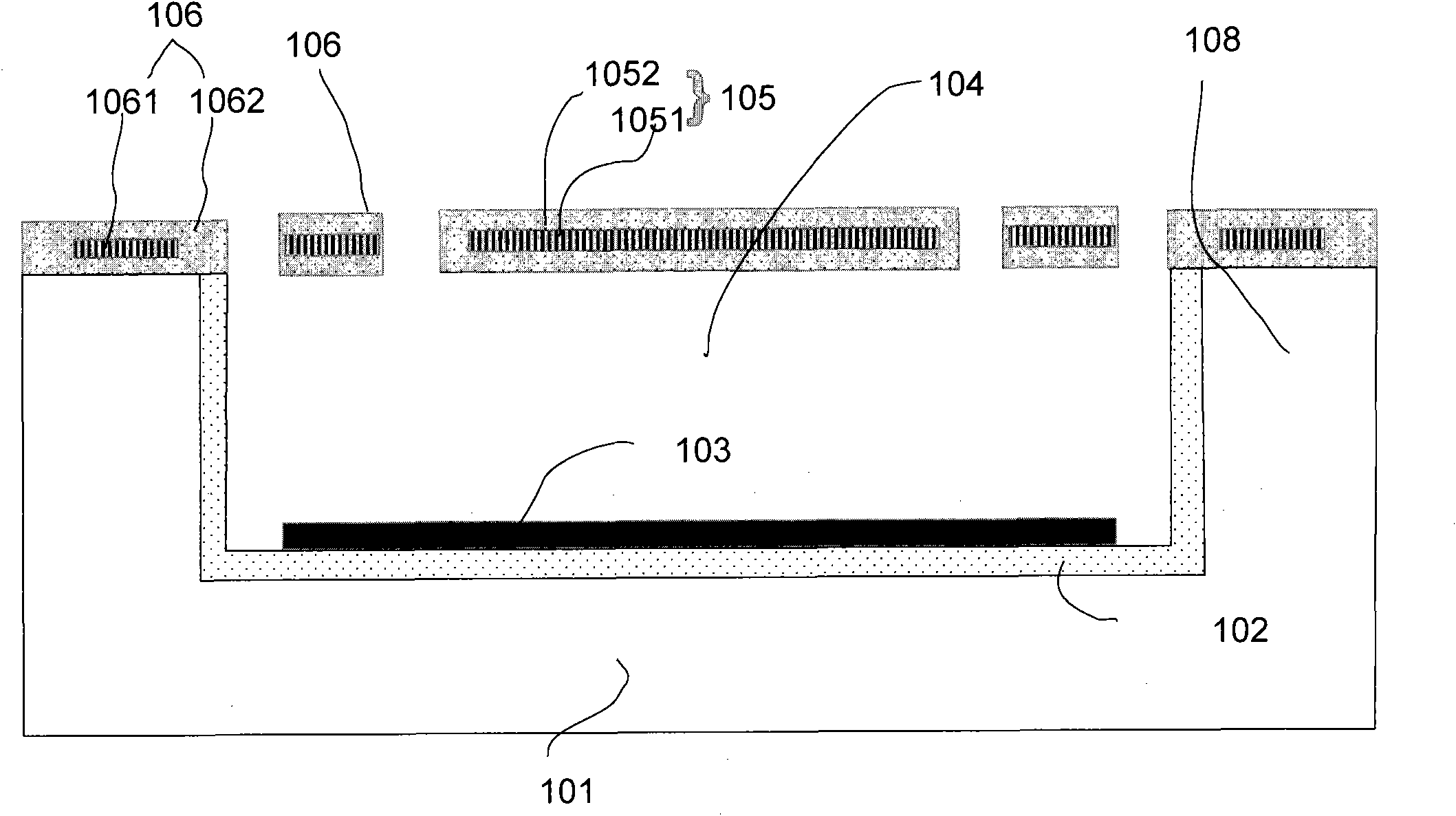

[0086] Figure 16 It is a schematic structural diagram of the infrared focal plane array device in this embodiment, Figure 17 for Figure 16 The top view of the figure shows only one detection unit, Figure 18 for Figure 17 Schematic diagram of the detection cell array.

[0087] Such as Figure 16 , 17 As shown, the difference from the previous embodiments is that the cantilever beam 306 is disposed above the heat sink 308 around the cavity 304 , with a gap between the cantilever beam 308 and the heat sink 308 . An anchor 309 is used to connect one end of the cantilever beam 306 to the heat sink and the other end to the infrared sensitive layer 305 to support the entire infrared sensitive layer. In this way, the infrared sensitive layer 305 can cover almost the entire upper area of the cavity 304 , which increases the effective reflection area of the resonant absorption structure, thereby improving the absorption efficiency of the infrared sensitive layer 305 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com