Process for curing and dehydrating scum bottom sludge

A bottom sludge and scum technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of inability to achieve rapid dehydration of scum and bottom sludge, small processing capacity, large investment, etc., and achieve easy stacking, treatment, and dehydration The effect of high speed and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

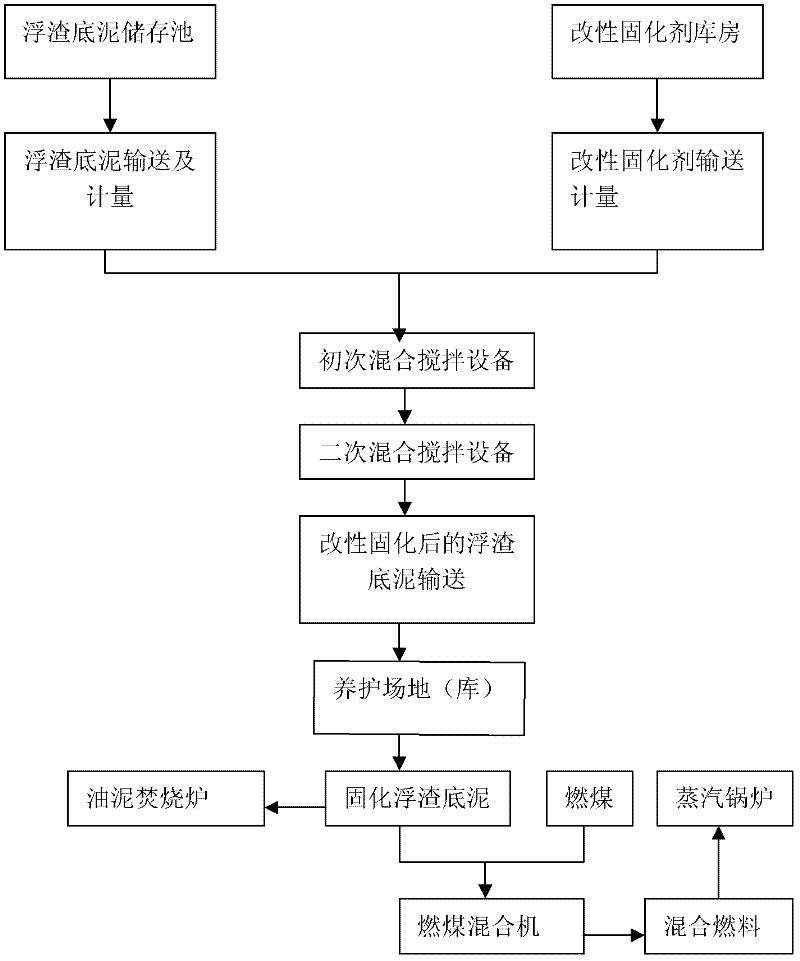

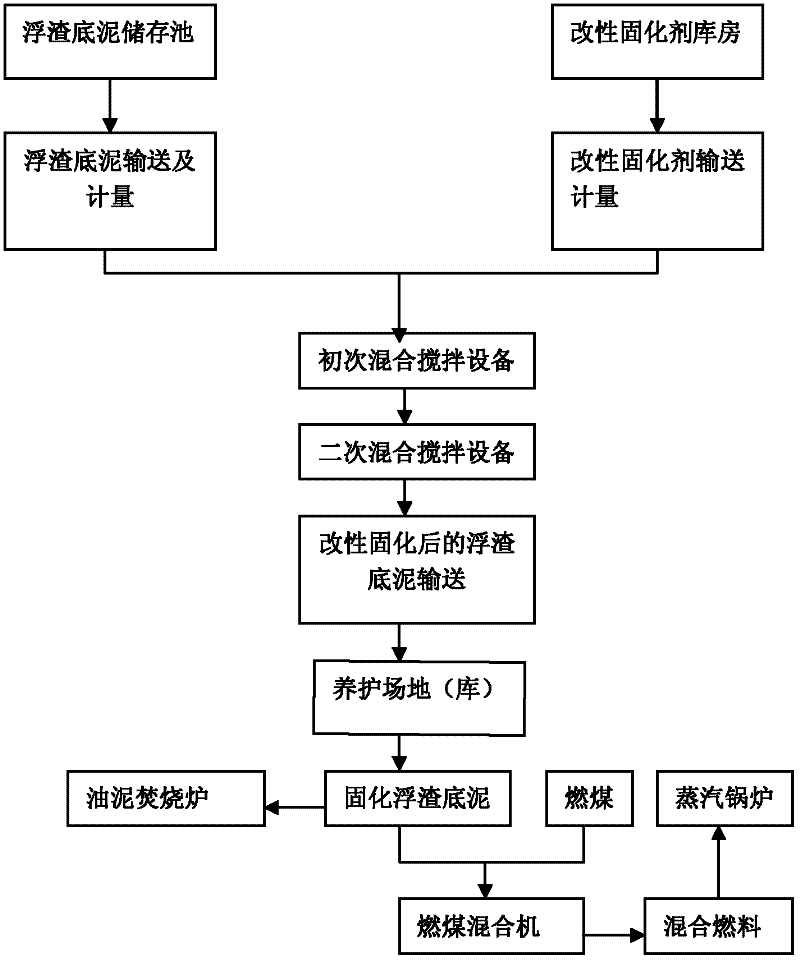

[0011] As shown in the accompanying drawing, a kind of scum bottom sludge solidification and dehydration process, the process steps are as follows: after the scum bottom sludge is metered by a metering pump, it is pumped into the initial mixing agitator, according to curing agent: scum bottom sludge=3: Take the curing agent at a ratio of 17, and the curing agent is adjusted and propelled into the primary mixing agitator by the screw metering propeller according to the ratio, the stirring speed is 50 rpm, stirred for 5 minutes, and discharged into the secondary mixing agitator, the stirring speed is 150 rpm Minutes, stirring for 10 minutes, the scum bottom sludge after modification and solidification is converted from a colloidal structure to a crystal structure, and then transported to the drying site by a slurry pump, and maintained for 1-3 days, and the scum bottom sludge after forming a crystal structure, so Part of the water content is crystallized, and the other part evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com