Synthetic method of dichlorobenzonitrile

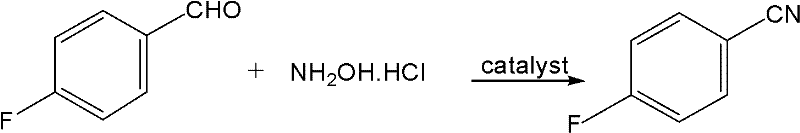

A technology for the synthesis of p-fluorobenzonitrile, which is applied in the direction of nitrogen oxide-organic compound reaction preparation, chemical recovery, organic chemistry, etc., can solve the problems of high temperature requirements, increased energy consumption, etc., and achieve mild reaction conditions , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

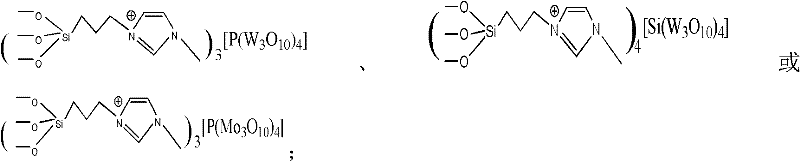

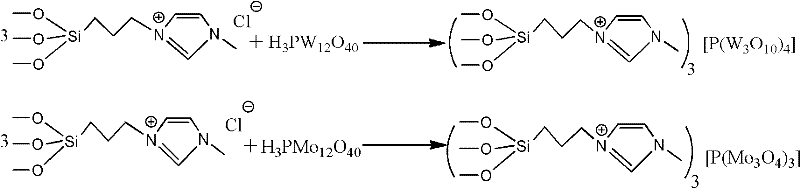

[0030] Embodiment 1: the preparation of phosphotungstic acid tetramethylammonium salt catalyst (catalyst A)

[0031] h 3 PW 12 o 40 +3(CH 3 ) 4 NOH→[(CH 3 ) 4 N] 3 [P(W 3 o 10 ) 4 ]

[0032] Tetramethylammonium hydroxide (25% aqueous solution) 1.5g, phosphotungstic acid 3.9g, add 20ml water and stir for 3h, then add 2.8g silicon oxide and stir for 24h, evaporate the solvent to obtain the desired catalyst; wherein phosphotungstate and The mass ratio of silicon oxide is 1.5:1.

Embodiment 2

[0033] Embodiment 2: the preparation of silicotungstic acid tetraethylammonium salt catalyst (catalyst B)

[0034] h 4 SiW 12 o 40 +4(C 2 h 5 ) 4 NOH→[(C 2 h 5 ) 4 N] 4 [Si(W 3 o 10 ) 4 ]

[0035] Tetraethylammonium hydroxide (25% aqueous solution) 3.8g, silicotungstic acid 4.8g, add 20ml water and stir for 3h, then add 2.8g silicon oxide and stir for 24h, evaporate the solvent to obtain the required catalyst; wherein silicotungstate and The mass ratio of silicon oxide is 2:1.

Embodiment 3

[0036] Embodiment 3: the preparation of phosphomolybdic acid tetramethylammonium salt catalyst (catalyst C)

[0037] h 3 PMo 12 o 40 +3(CH 3 ) 4 NOH→[(CH 3 ) 4 N] 3 [P(Mo 3 o 10 ) 4 ]

[0038] Tetrabutylammonium hydroxide (40% solution) 6.2g, phosphomolybdic acid 6g, add 20ml water and stir for 3h, then add 2.8g silicon oxide and stir for 24h, evaporate the solvent to obtain the desired catalyst; wherein the mass of phosphomolybdate and silicon oxide The ratio is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com