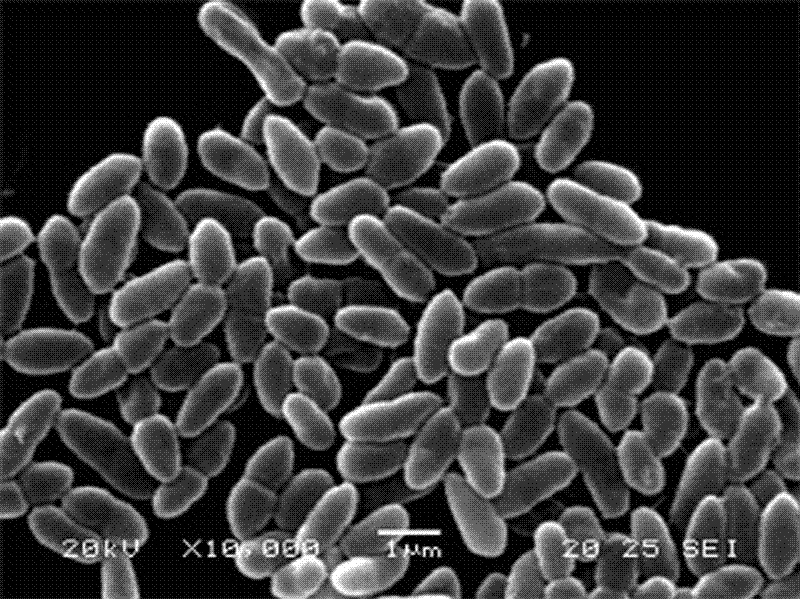

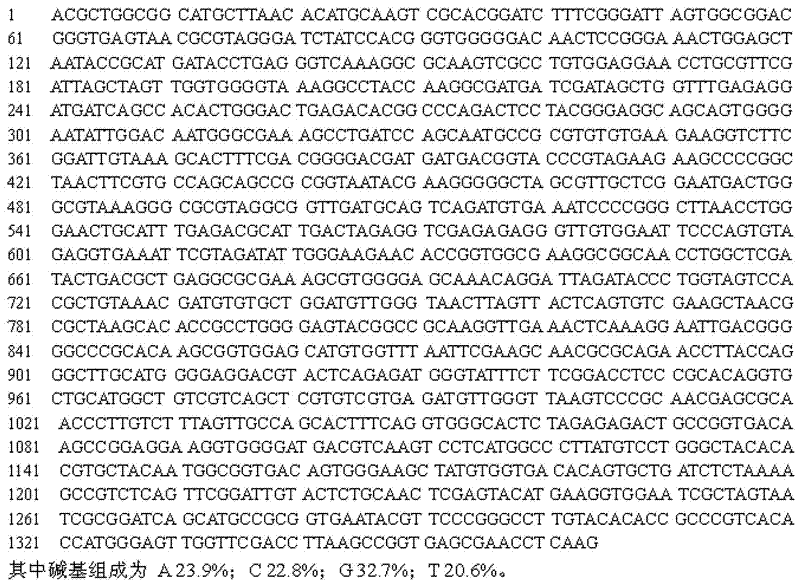

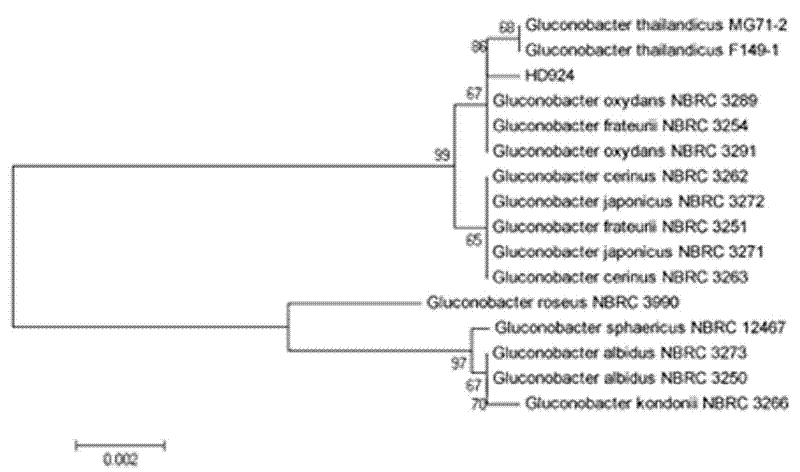

Strain HD924 for producing dihydroxyacetone by microbial fermentation and method

A kind of technology of dihydroxyacetone and HD924, applied in the field of fermenting glycerol to produce dihydroxyacetone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for producing dihydroxyacetone by fermenting glycerol with the bacterial strain HD924 is specifically as follows: the bacterial strain HD924 is first inoculated into a primary seed medium with a 10% inoculum size (the composition of the primary seed medium is: glycerol 30g / L, yeast powder 15g / L, KH 2 PO 4 0.3g / L, pH natural), cultured aerobically at 28°C for 24h; then the cultured primary seeds were inserted into the secondary seed medium at an inoculum size of 5% (the composition of the secondary seed medium was : Glycerin 30g / L, yeast powder 15g / L, CaCO 3 0.3g / L, pH 6.0), after 8 hours, put the cultured secondary seeds into the fermentation medium containing different glycerin concentrations (250mL triangular flask, liquid volume 50mL) at 200 rpm / min, fermented at 28°C for 48 h, and measured the content of dihydroxyacetone. The experimental results are shown in Table 4.

[0040] Wherein, the composition of the fermentation medium is: glycerol 50~350g...

Embodiment 2

[0043] Put the cultured secondary seeds into 5% inoculum of glycerol (glycerin comes from food grade glycerol, industrial grade glycerol and saponified crude glycerol respectively) into the fermentation medium with a concentration of 100g / L (250mL Erlenmeyer flask, filled with liquid volume 50mL) at 200 rpm, fermented at 28°C for 72 hours, and measured the content of dihydroxyacetone. The experimental results are shown in Table 5. Wherein, the fermentation medium consists of: glycerol 100g / L, yeast powder 10g / L, CaCO 3 3g / L, pH 6.0; the purity of food grade glycerin is 99.5%, the purity of industrial grade glycerin is 95%, and the saponified crude glycerin is waste glycerin from soap making industry (purity 60%). One, the cultivation of secondary seed is identical with embodiment 1.

[0044]

Embodiment 3

[0046] Utilize the method for producing dihydroxyacetone by fermenting glycerol with the bacterial strain HD924, specifically: the bacterial strain HD924 is directly inserted into the fermentation medium (250mL triangular flask, liquid capacity 50mL; the fermentation medium consists of: Food grade glycerol 100g / L, peptone 8g / L, calcium carbonate 5g / L, culture medium pH 7), rotating speed 200 rpm, fermented at 30°C for 72 h under aerobic conditions; The content of hydroxyacetone was 67.4 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com