Method for online in-situ monitoring of solid-state fermentation fungus biomass

A solid-state fermentation and biomass technology, which is applied in microorganism-based methods, biochemical equipment and methods, and microbial determination/inspection, etc., can solve the problem that biomass cannot be accurately measured online, and achieve strong repeatability and little impact. , the effect of measuring a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 On-line in-situ monitoring of biomass changes in the solid-state fermentation process of Trichoderma viride

[0023] Trichoderma viride is the main production strain of cellulase produced by solid-state fermentation, and the fermentation substrate is lignocellulosic material. In this embodiment, the steps for on-line in-situ monitoring of Trichoderma viride solid-state fermentation to produce cellulase are as follows:

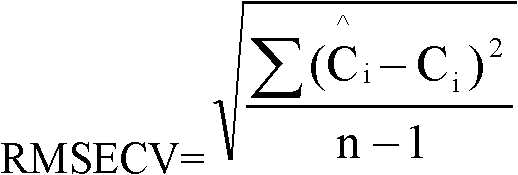

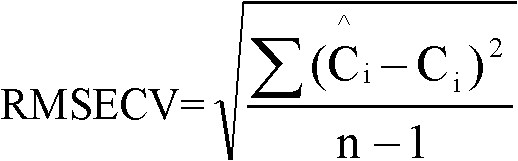

[0024] 1. Modeling sample preparation. Use steam-exploded rice straw and wheat bran (ratio: 4:1) as the solid-state fermentation medium, adjust the water content of the medium to about 75%, and inoculate 10% Trichoderma viride spore liquid (concentration: 5 × 108 / mL ), cultured for 7 days at a temperature of 30°C and a humidity of 98%, and 50 groups of parallel experiments were done. Three groups of fermented products were taken every 12 hours and photographed with a high-resolution digital camera, and the biomass in the fermented products wa...

Embodiment 2

[0040] Example 2 On-line in-situ detection of biomass changes during solid-state fermentation of Aspergillus niger

[0041] Aspergillus niger is the main production strain of α-acid amylase by solid-state fermentation. The fermentation substrate is 85% bran, 10% corn starch, 5% bean cake powder, and the ratio of material to water is 1:1. In this embodiment, the steps for on-line in situ monitoring of Aspergillus niger solid-state fermentation to produce α-acid amylase are as follows:

[0042] 1. Modeling sample preparation. With 85% bran, 10% corn starch, and 5% bean cake powder as the solid-state fermentation medium, adjust the water content of the medium at about 60%, and inoculate 10% Aspergillus niger spore liquid (concentration is 5 × 108 / mL ), cultured for 5 days at a temperature of 30°C and a humidity of 98%, and 50 groups of parallel experiments were done. Three bottles of fermented product were taken every 12 hours and photographed with a high-resolution digital cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com