Fully-closed circulating water system for recovering latent heat of condensing generation units by utilizing air cooler

A technology of condensing unit and circulating water system, which is used in steam engine installations, machines/engines, steam applications, etc., can solve problems such as increased fuel consumption, pollution, waste, etc., to reduce fuel consumption, avoid corrosion, and facilitate layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

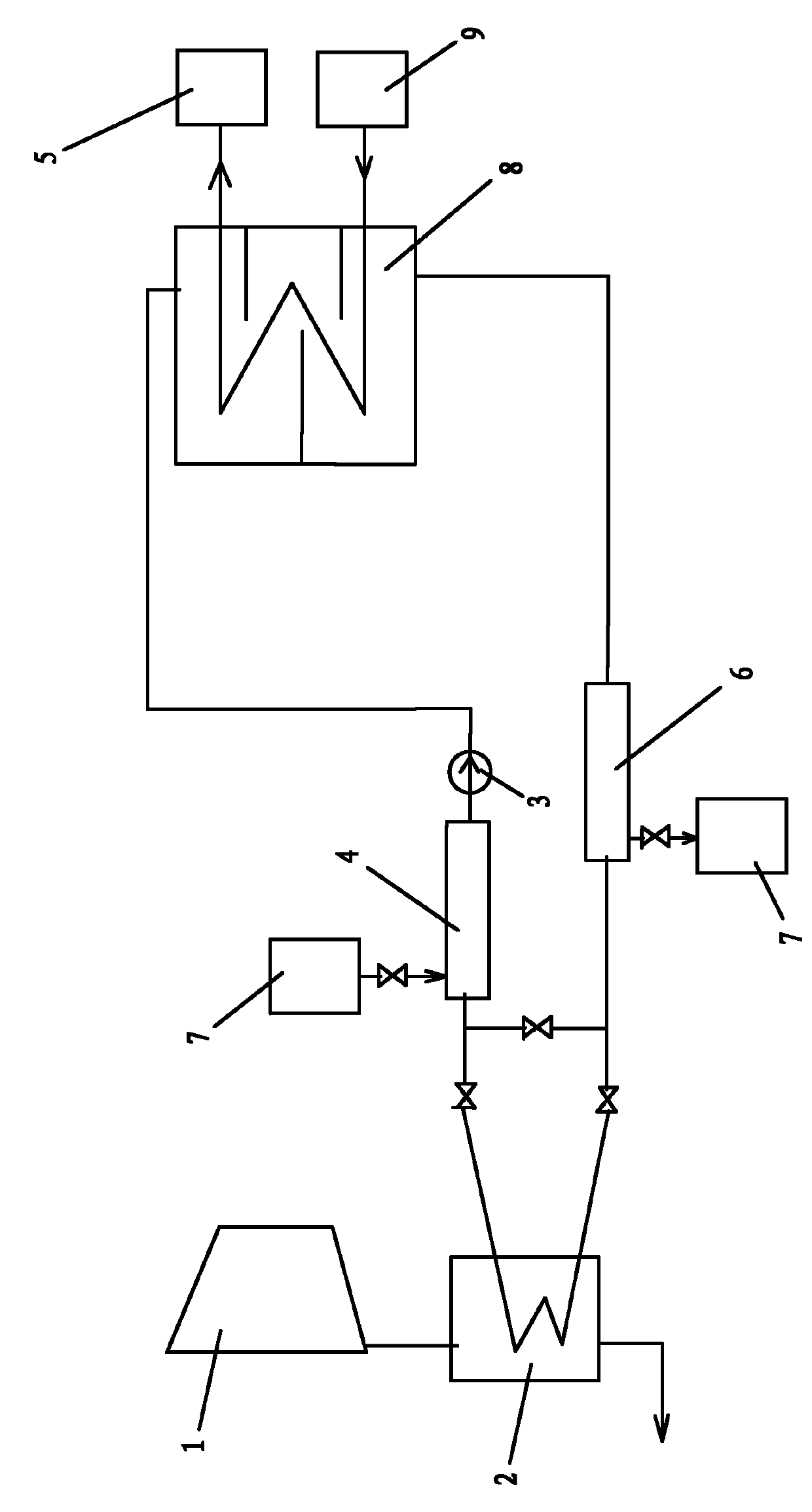

[0027] The fully enclosed circulating water system of the present invention utilizing the air cooler to recover the latent heat of the condensing unit is as follows: figure 1 As shown, it includes a steam turbine 1 and a boiler 5 used in conjunction with the steam turbine 1, the steam exhaust outlet of the steam turbine 1 is connected with a condenser 2, and also includes a water collecting pipe 4 containing the treated circulating medium, a circulating water pump 3, an air cooling 8 and the water distribution pipe 6, the circulating water outlet of the condenser 2 is connected with the water inlet of the water collecting pipe 4, and the water outlet of the water collecting pipe 4 is connected with the water inlet of the circulating water pump 3. The water outlet is connected with the water inlet of the air cooler 8, the water outlet of the air cooler 8 is connected with the water inlet of the water distribution pipe 6, and the water outlet of the water distribution pipe 6 is c...

Embodiment 2

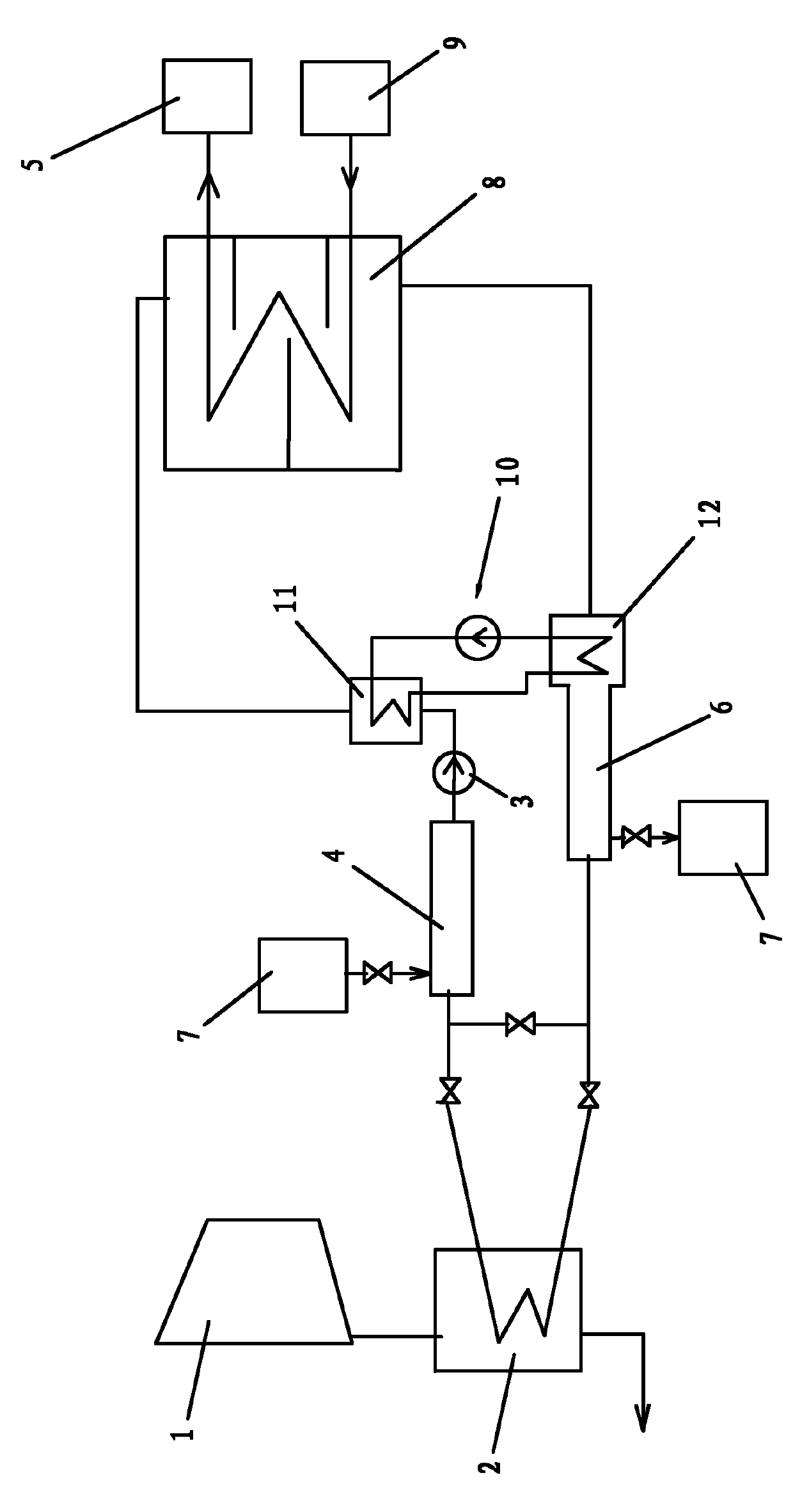

[0041] like figure 2 As shown, the difference between this embodiment and the first embodiment is that this embodiment further includes a refrigerator 10, and the refrigerator 10 includes a condenser 11 and an evaporator 12, and the condenser 11 is disposed in the air cooler 8 Between the circulating water pump 3 , the evaporator 12 is arranged between the air cooler 8 and the water distribution pipe 6 .

[0042] When the summer is hot, the setting of the refrigerator 10 is conducive to further cooling the circulating medium, so that the vacuum in the condenser 2 can be kept in the most economical state, and the condenser 11 and the evaporator 12 of the refrigerator 10 are arranged in the air cooling. On both sides of the condenser 8, when the temperature of the water flowing through the air cooler 8 does not meet the needs of the condensing unit, the refrigerator 10 will be activated. The supply air is exchanged in the device 8. The condenser 11 and evaporator 12 of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com