Manufacturing process of electrolyte for oxidation reduction cell

A manufacturing method and electrolyte technology, which are applied in indirect fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of complex manufacturing process, danger, delay in the popularization of redox batteries, etc., and achieve easy drug management and observation. , automatic operation simple and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

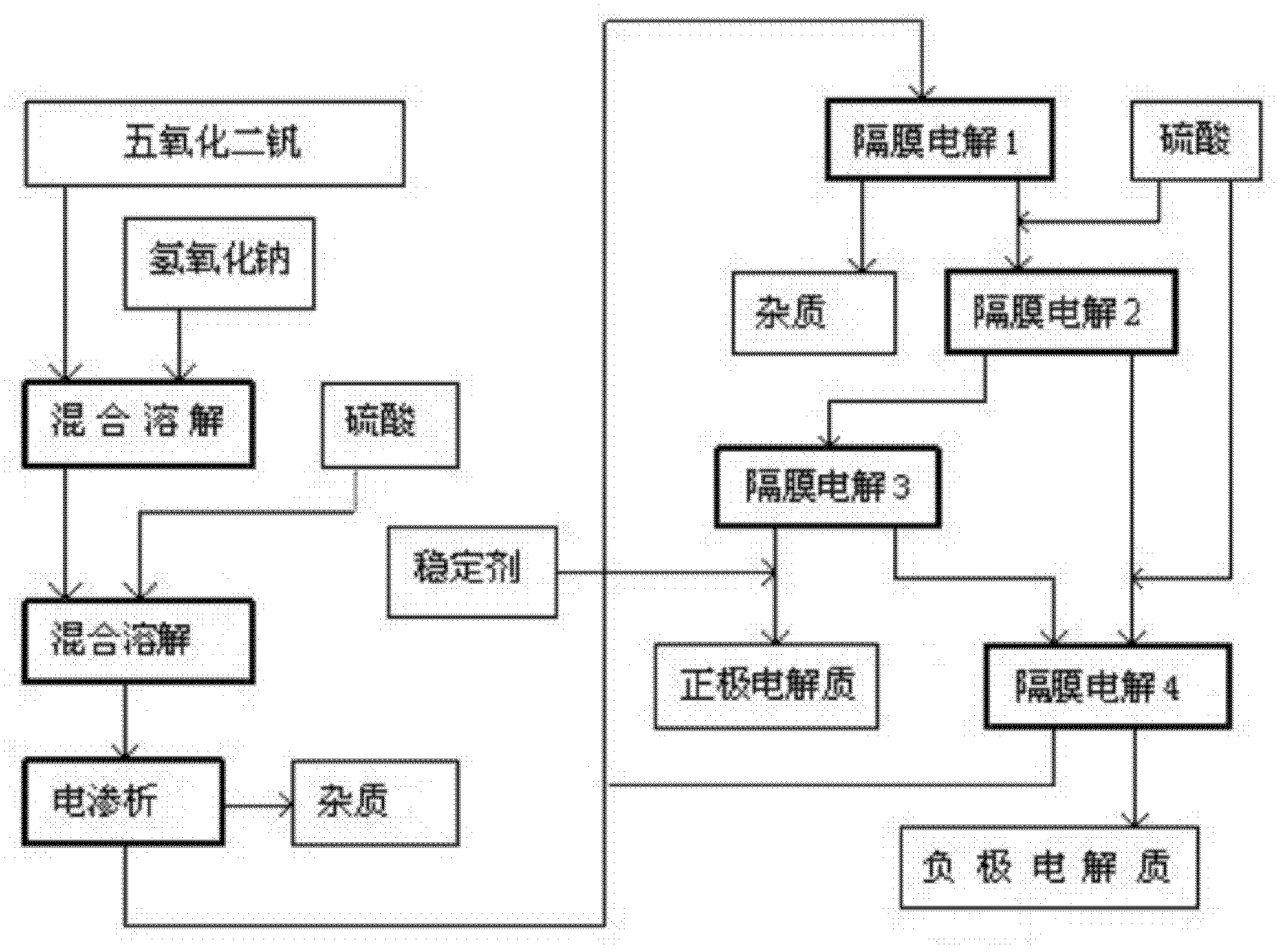

[0041] Such as figure 1 A method for manufacturing an electrolyte for a redox battery shown, the process steps are as follows:

[0042] (1) Slowly add vanadium pentoxide to the aqueous sodium hydroxide solution with a concentration of 20wt% and keep stirring, the stirring rate is controlled at 120rpm, and the addition of vanadium pentoxide is 25wt% of the quality of the alkaline aqueous solution. The speed of adding vanadium pentoxide is preferably not to produce a large amount of precipitates, and the adding time is 30 minutes;

[0043] (2) After the vanadium pentoxide addition is completed, continue to stir, and the stirring rate is controlled at 30rpm, and continues to stir for 50 minutes to make it fully dissolve;

[0044] (3) Slowly add sulfuric acid with a concentration of 25 wt% into the above system to react to generate vanadyl(IV) sulfate, stop adding when the pH value of the system reaches 2.0 to 2.2, and continue the reaction for 30 minutes;

[0045] (4) remove so...

Embodiment 2

[0052] Such as figure 1 A method for manufacturing an electrolyte for a redox battery shown, the process steps are as follows:

[0053] (1) Slowly add vanadium pentoxide to the aqueous sodium hydroxide solution with a concentration of 30wt% and keep stirring, the stirring rate is controlled at 80rpm, and the addition of vanadium pentoxide is 40wt% of the quality of the alkaline aqueous solution. The speed of adding vanadium pentoxide is advisable not to produce a large amount of precipitates, and the adding time is 60 minutes;

[0054](2) After the vanadium pentoxide addition is completed, continue to stir, and the stirring rate is controlled at 50rpm, and continues to stir for 30 minutes to make it fully dissolve;

[0055] (3) Slowly add sulfuric acid with a concentration of 20 wt% into the above system to react to generate vanadyl(IV) sulfate, stop adding when the pH value of the system reaches 2.0 to 2.2, and continue the reaction for 20 minutes;

[0056] (4) remove sodiu...

Embodiment 3

[0062] Such as figure 1 A method for manufacturing an electrolyte for a redox battery shown, the process steps are as follows:

[0063] (1) Slowly add vanadium pentoxide to the potassium hydroxide aqueous solution with a concentration of 20wt% and keep stirring, the stirring rate is controlled at 150rpm, and the addition of vanadium pentoxide is 25wt% of the potassium hydroxide aqueous solution quality. The speed of adding vanadium pentoxide is preferably not to produce a large amount of precipitates, and the adding time is 30 minutes;

[0064] (2) After the vanadium pentoxide addition is completed, continue to stir, and the stirring rate is controlled at 60rpm, and continues to stir for 30 minutes to make it fully dissolve;

[0065] (3) Slowly add sulfuric acid with a concentration of 30wt% into the above system to react to generate vanadyl(IV) sulfate, stop adding when the pH value of the system reaches 2.0 to 2.2, and continue the reaction for 30 minutes;

[0066] (4) rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com