Production method of high-permeability low-density lithium battery polyolefin diaphragm

A technology of polyolefin diaphragm and production method, which is applied to battery components, circuits, electrical components, etc., can solve the problems of complex process, uneconomical cost, high cost, etc., achieve uniform temperature, enhance uniformity, increase packaging corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

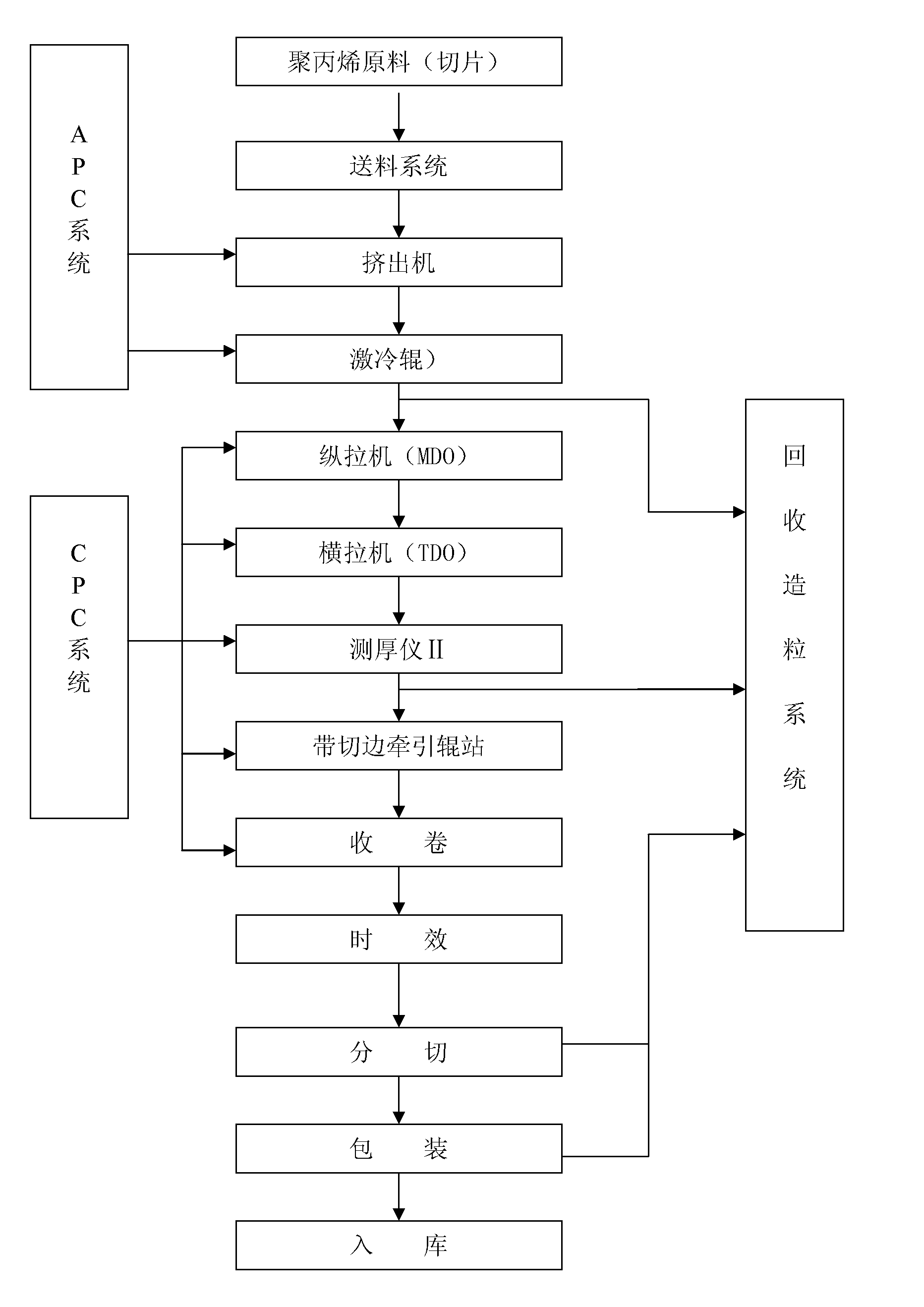

[0012] A kind of production method of polyolefin membrane of high permeability low density lithium battery of the present invention is characterized in that it comprises following production steps:

[0013] (1) To make a nucleating agent, 20~45% of N,N-dicycloethyl-2,6 naphthalene diamide; 30~60% of N,N-bicycloethyl terephthalamide, A mixture of 0.5-8% calcium salt of suberic acid and 0.5-6% titanium dioxide, 1-6% calcium carbonate and other inorganic salts mixed with 4-6% polypropylene homopolymer as a masterbatch get nucleating agent;

[0014] (2) Mix 50-80% of metallocene-catalyzed polypropylene homopolymer with 20-50% of metallocene-catalyzed polypropylene block copolymer and 1-4% of nucleating agent, Extruded in the extruder, the angle of the die head of the extruder is adjustable, the raw material is melted and plasticized at a high temperature of 170-260 degrees, and extruded from the die head, and then chilled on a chilled roller at 100-150 degrees Celsius Cool for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com