DC/AC grid connected inverter circuit and power factor adjusting method

A technology of inverter circuit and circuit, which is applied in the direction of control/regulation system, reactive power adjustment/elimination/compensation, and adjustment of electrical variables, etc., and can solve large switching noise, current ripple amplitude, and common-mode voltage amplitude change Large, large switching tube loss and other problems, to achieve the effect of suppressing common mode current, reducing EMI, and strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

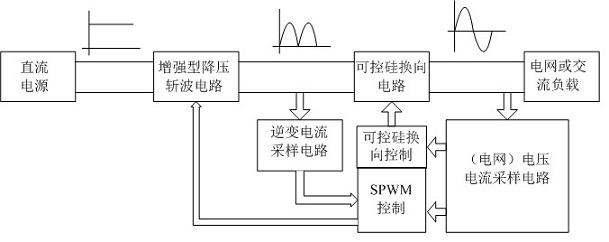

[0034] Such as figure 1 , image 3 , Figure 4 , Figure 5 As shown, the DC / AC grid-connected inverter circuit includes enhanced step-down chopper circuit, thyristor commutation circuit, inverter current sampling circuit, voltage and current detection circuit, thyristor commutation control circuit and SPWM control circuit .

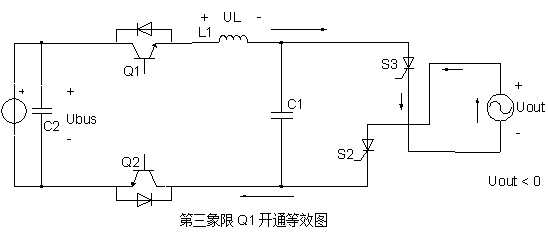

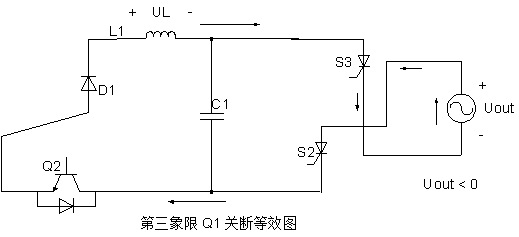

[0035] The enhanced step-down chopper circuit includes power switch Q1 (MOSFET or IGBT), power switch Q2 (MOSFET or IGBT), diode D1, diode D2, inductor L1 and capacitor C1, power switch Q1 drain (or collector ) is connected to the anode of the DC power supply and the cathode of the diode D2, its source (or emitter) is connected to one end of the inductor L1 and the cathode of the diode D1, and the drain (or collector) of the power switch tube Q2 is connected to the anode of the diode D2 and the capacitor C1 One end is connected to the cathode of the one-way thyristor S2 and S4 in the commutation circuit, its source (or emitter) is connected to the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com