Method for removing heavy metal ions from tobacco extract

A technology of heavy metal ions and extracts, applied in tobacco, tobacco treatment, application, etc., can solve the problems of limited treatment efficiency, difficult treatment, complicated operation of biological treatment technology, etc., achieve simple steps, improve removal rate, and improve social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

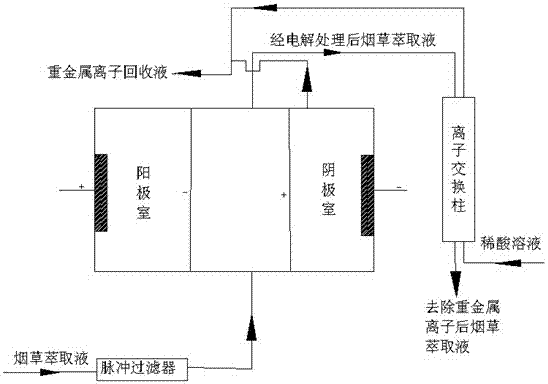

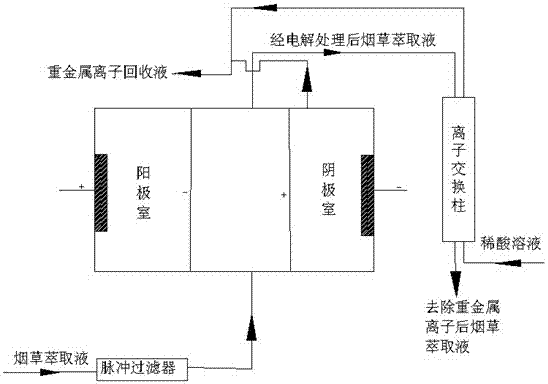

Method used

Image

Examples

Embodiment 1

[0025] The tobacco extract filtered by the pulse filter (filtering precision is 0.3μm) is first passed through the electrolysis device for constant current electrolysis, the current density is 1000A / m 2 The electrolysis time is 2h. After the electrolysis treatment is completed, the heavy metals in the cathode chamber of the electrolysis device are recovered by sulfide precipitation method, and the tobacco extract after the electrolysis treatment is passed through a cation exchange resin column with a height-to-diameter ratio of 10:1. The flow rate of the tobacco extract in the cation exchange resin column is 1 bed volume / h, and the effluent is taken under the ion exchange column to obtain the tobacco extract that removes heavy metal ions. The saturated cation exchange resin column is regenerated with a hydrochloric acid solution with a concentration of 2% by volume and reused. At the same time, the heavy metal ions in the eluent are subjected to the sulfide precipitation method (...

Embodiment 2

[0028] The tobacco extract filtered by a pulse filter (with a filtration accuracy of 5μm) is first passed through the electrolysis device for constant current electrolysis, with a current density of 800A / m 2 The electrolysis time is 2h. After the electrolysis treatment is completed, the heavy metals in the cathode chamber of the electrolysis device are recovered by sulfide precipitation method, and the tobacco extract after the electrolysis treatment is passed through a cation exchange resin column with a height-to-diameter ratio of 10:1. The flow rate of the tobacco extract in the cation exchange resin column is 3 times the bed volume / h, and the effluent is taken under the ion exchange column to obtain the tobacco extract with heavy metal ions removed. The saturated cation exchange resin column is regenerated with a 10% hydrochloric acid solution by volume percentage and reused. At the same time, the heavy metal ions in the eluent are subjected to the sulfide precipitation metho...

Embodiment 3

[0031] The tobacco extract filtered by the pulse filter (filtering precision is 3μm) is first passed through the electrolysis device for constant current electrolysis, the current density is 600A / m 2 The electrolysis time is 2h. After the electrolysis treatment is completed, the heavy metals in the cathode chamber of the electrolysis device are recovered by sulfide precipitation method, and the tobacco extract after the electrolysis treatment is passed through a cation exchange resin column with a height-to-diameter ratio of 10:1. The flow rate of the tobacco extract in the cation exchange resin column is 5 times the bed volume / h, and the effluent is taken under the ion exchange column to obtain the tobacco extract from which heavy metal ions are removed. The saturated cation exchange resin column is regenerated with 5% hydrochloric acid solution by volume percentage and reused. At the same time, the heavy metal ions in the eluent are subjected to the sulfide precipitation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com