Preparation method for phase-change energy-storage microcapsule and phase-change energy-storage microcapsule

A phase-change energy storage and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of high brittleness of the wall material, low encapsulation rate, complicated process, etc., and achieve thermal stability Good performance, good capsule dispersibility, and simple preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

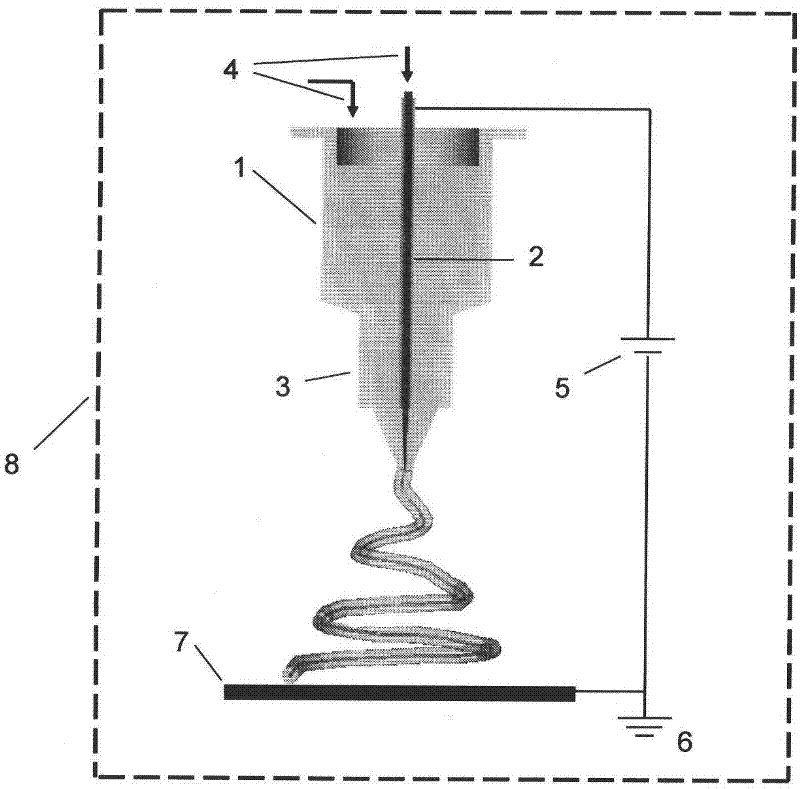

[0044] See figure 1 . use as figure 1 The shown device prepares phase-change energy storage microcapsules, and the device includes a coaxial composite spinneret 3 composed of an outer nozzle 1 and an inner nozzle 2 made of metal materials, an internal and external fluid infusion system 4, and a DC high-voltage power supply 5. Ground wire 6, collecting device 7 and heating temperature control system 8;

[0045] The inside of a heating temperature control system (temperature control box) 8 is provided with the coaxial composite spinneret 3 composed of the outer nozzle 1 and the inner nozzle 2, the internal and external fluid infusion system 4, the DC high voltage power supply 5, Ground wire 6 and collecting device 7; Wherein, described outer spray pipe 1 and inner spray pipe 2 are connected with the positive pole of described DC high voltage power supply 5 by wire, and the negative pole of DC high voltage power supply 5 is grounded through ground wire 6; The collecting device...

Embodiment 2

[0048] The device of Example 1 was used.

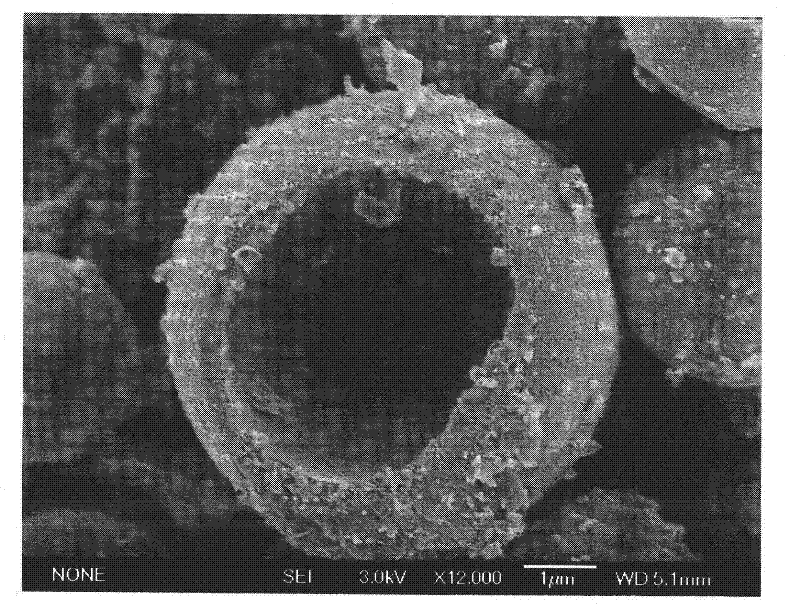

[0049] Add 2g of polyvinylpyrrolidone to the mixed solution of 4g of ethanol and 8g of acetic acid, and add 7g of Ti(OiPr) after completely dissolving 4 and 7gVO(OiPr) 3 After stirring evenly, a sol with a polyvinylpyrrolidone concentration of 7 wt% was formed as a shell solution. The shell solution is delivered to the outer nozzle at a rate of 1.0-5.0mL / h through the outer fluid infusion system. With capric acid as the core solution, it is delivered to the inner spray tube at a rate of 0.1-1mL / h through the internal fluid infusion system. The composite spinneret is connected to the positive pole of the high-voltage power supply, and the metal plate covered with aluminum foil is grounded as the collecting plate. The working voltage is 25-40KV. After axial electrospraying, the fluids of the shell solution and the core solution meet at the nozzle of the composite spinneret to form a composite fluid. The composite fluid is subjected t...

Embodiment 3

[0051] The device of Example 1 was used.

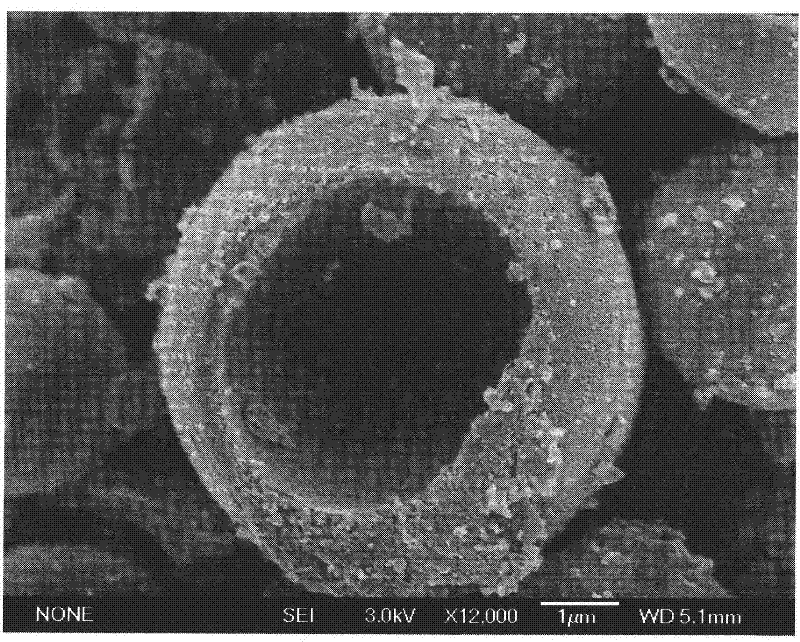

[0052] Add 4g of polyvinylpyrrolidone to the mixed solution of 8g of ethanol and 4g of acetic acid, and add 14g of Ti(OiPr) after completely dissolving 4 After stirring evenly, a sol with a polyvinylpyrrolidone concentration of 13 wt% was formed as a shell solution. The shell solution is delivered to the outer nozzle at a rate of 3.0-10.0mL / h through the outer fluid infusion system. With hexadecanoic acid as the core solution, it is delivered to the inner spray tube at a rate of 0.5-2mL / h through the internal fluid infusion system. The composite spinneret is connected to the positive pole of the high-voltage power supply, and the metal plate covered with aluminum foil is grounded as the collecting plate. The working voltage is 10-30KV. After axial electrospraying, the fluids of the shell solution and the core solution meet at the nozzle of the composite spinneret to form a composite fluid. The composite fluid is subjected to the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com