Plasma cladding method and automatic cladding equipment for manufacturing wear resistant clad steel plate

A technology of plasma cladding and composite steel plate, which is applied in the coating process and coating of metal materials, can solve the problems of large denaturation of wear-resistant composite steel plate and easy cracking and falling of wear-resistant layer, so as to reduce deformation and benefit fully Metallurgical reaction, beneficial to the effect of weld surface forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

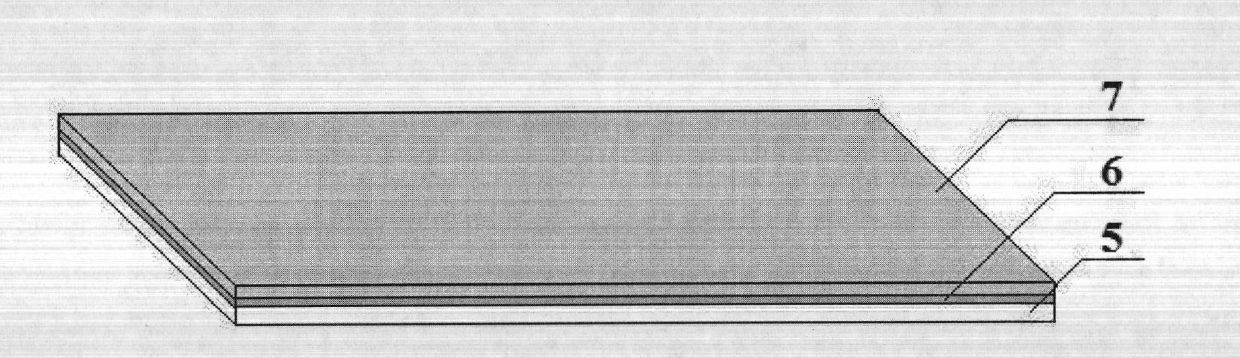

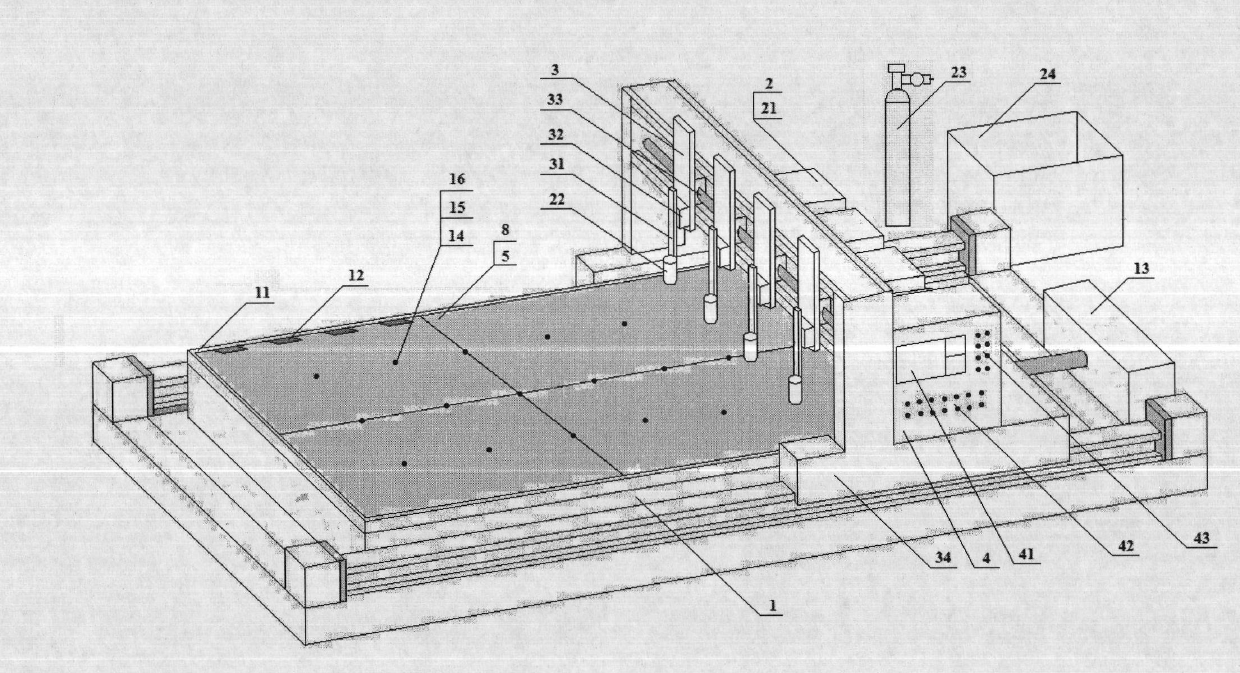

[0070] Example 1, taking the large-scale loading car liner in a mine as an example, the wear medium is ore, and the wear type is impact and abrasive wear. The size of each wear-resistant composite steel plate is required to be: length 3000mm × width 2000mm × thickness 15mm, of which Layer thickness (including fusion zone) ≥ 6mm, surface hardness HRC ≥ 60.

[0071] The Q345B plate with a length of 3100mm×width 2100mm×thickness of 10mm is selected as the base steel plate 5 (including the fixed part of the clamp), and a high-chromium cast iron type micro-slag wear-resistant alloy powder block material with a length of 80mm×width 30mm×thickness of 7mm is selected (the material available in the market) as the wear-resistant layer material.

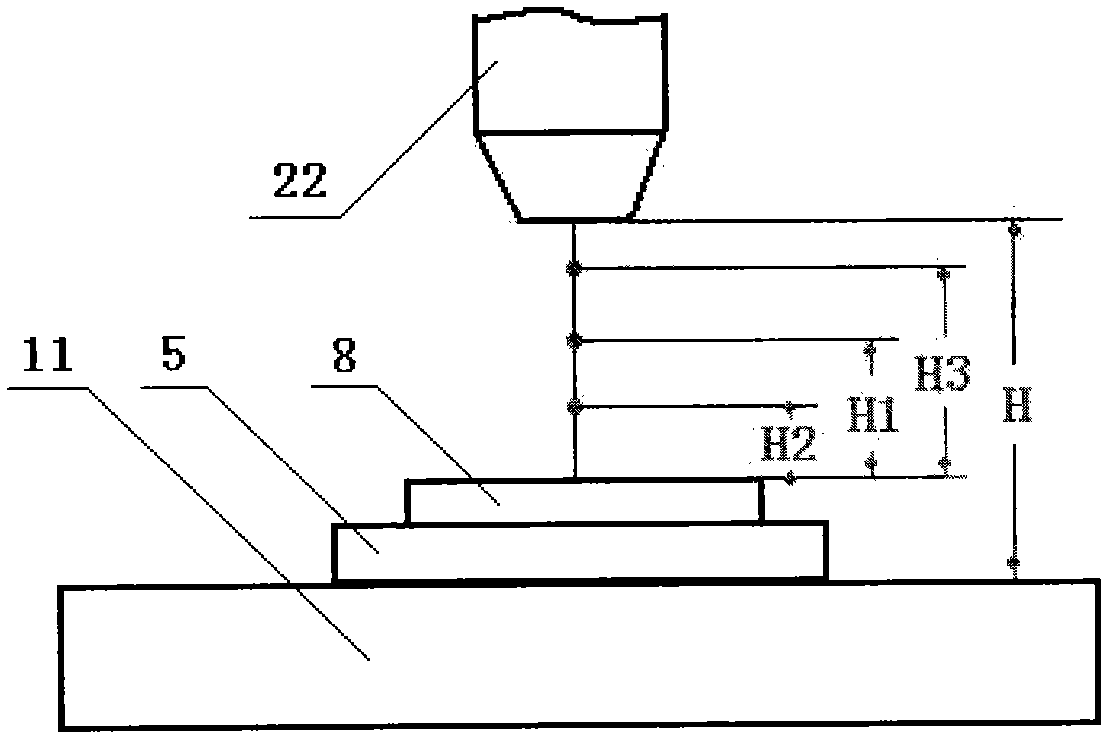

[0072] (1) The steps of the welding process technical scheme are as described above, and the operating trajectory and welding parameters are set as follows:

[0073] Plasma welding gun transverse gap swing width B: 45mm / each time, walking spee...

Embodiment 2

[0097] Embodiment 2, taking the waste discharge pipeline of a waste-to-energy plant as an example, the wear medium is dust, sand grains, iron chips, masonry blocks, the wear type is erosion wear, the pipe wall thickness is 20mm, and the side length is a square pipe with a side length of 600mm. The section length is 1000mm, and there are eight sections. At present, it is made of Q345B steel plate. After one month of use, the pipe wall is worn out and scrapped.

[0098]According to the use environment and wear type of the pipeline, considering the cost of the product, a Q235 plate with a length of 2500mm×width 2100mm×a thickness of 12mm is used as the base steel plate 5 (including the margin for pressing the four sides of the base plate by the clamp), and a length of 80mm× High chromium nickel tungsten carbide micro-slag wear-resistant alloy powder bulk material with a width of 30 mm × a thickness of 10 mm (the material is available in the market). Adopt the four-gun plasma clad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com