Method and device for converting direct current into alternating current

An alternating current and direct current technology, which is applied in the direction of converting irreversible direct current power input into alternating current power output, output power conversion devices, electrical components, etc. Short time and other problems, to achieve the effects of high output voltage accuracy, reduced volume and weight, and long continuous working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the present invention in further detail with reference to the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

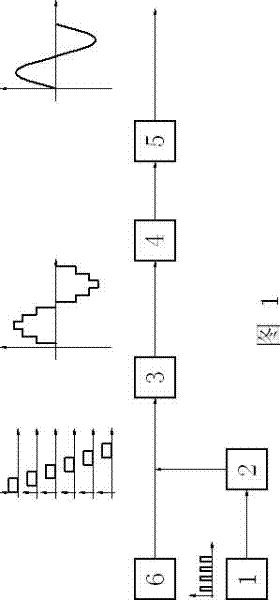

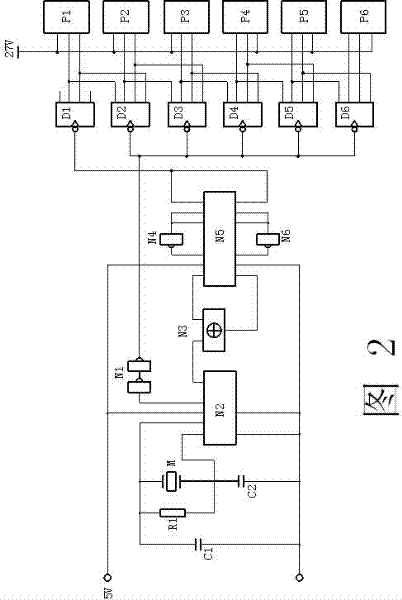

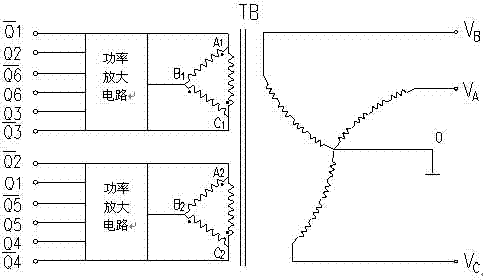

[0024] Examples. The invention is like figure 1 Shown. A method of converting direct current to alternating current. This method is to convert the direct current power into a set of quasi-square waves with a difference of π / 6n between each other through a 3n (n is a natural number) phase splitting circuit. After the power is amplified by a power amplifier circuit, The primary side of the transformer superimposes 6n groups of quasi-square waves according to the law of sine amplitude into a step wave similar to the sine wave to cancel out the higher harmonics; after filtering on the secondary side of the transformer, a pure AC power source is obtained. The phase splitting circuit uses a crystal oscillator as an oscillation source to form an RC clock circuit. The crystal osc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com