Dust removal method and device based on chemical agglomeration and split linked anode electric dust removal

A chemical agglomeration and electrostatic precipitator technology, applied in electrostatic separation, electrode cleaning, etc., can solve problems such as the difficulty in maintaining the synergy between the electrostatic collection area and the bag filter area for a long time, high investment and operating costs, and increase in the dust collection area. Corona and secondary dust problems, low investment and operating costs, and the effect of solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

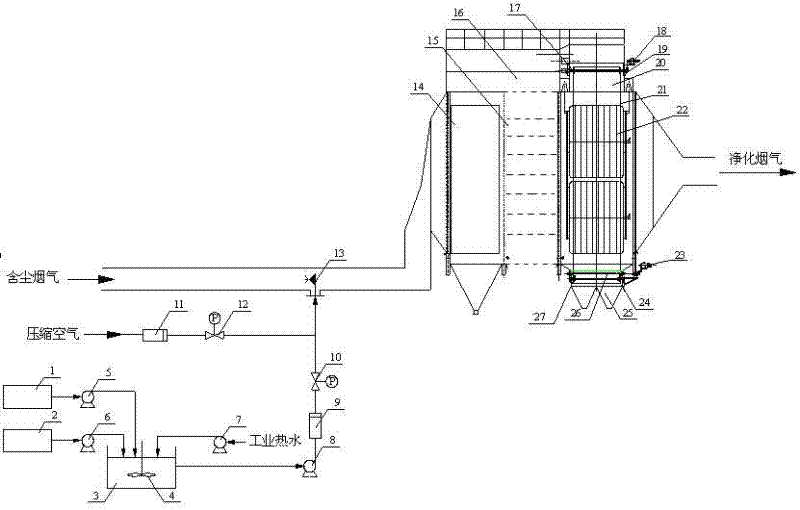

[0032] A dust removal method based on chemical agglomeration and split linkage anode type electrostatic precipitator. The agglomerating agent solution is sprayed into the inlet flue of the electrostatic precipitator through a two-fluid atomizing nozzle, and the agglomerating agent solution is sprayed together with compressed air. The material binder and the fine dust are connected through the long polymer chain with polar groups to increase the particle size of the fine dust, and then enter the electrostatic precipitator unit for removal; the injection amount of the agglomerating agent solution is per Nm 3 Flue gas 0.005~0.05kg; The agglomerating agent solution is composed of the following components in mass percentage:

[0033] High polymer binder 0.05~0.50%

[0034] Wetting agent 0.005~0.10%

[0035] The surplus of hot water at a temperature of 50-60°C.

[0036]The agglomerating agent solution sprayed through the two-fluid atomizing nozzle is in the form of fine droplets w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com