Submerged arc welding controller

A submerged arc welding and controller technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low speed change rate, complicated operation, complex structure, etc., and achieve small size, strong anti-interference, anti- strong interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

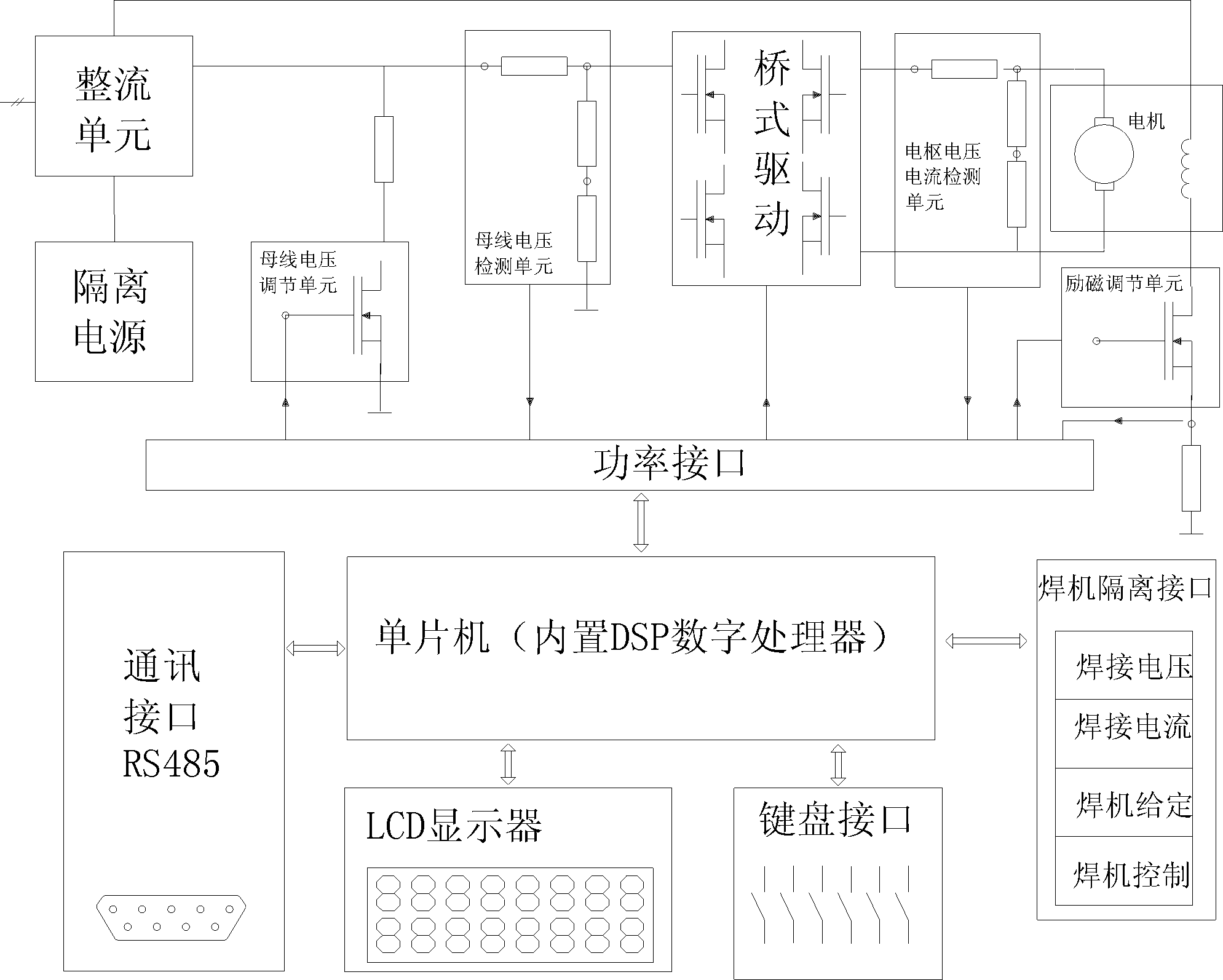

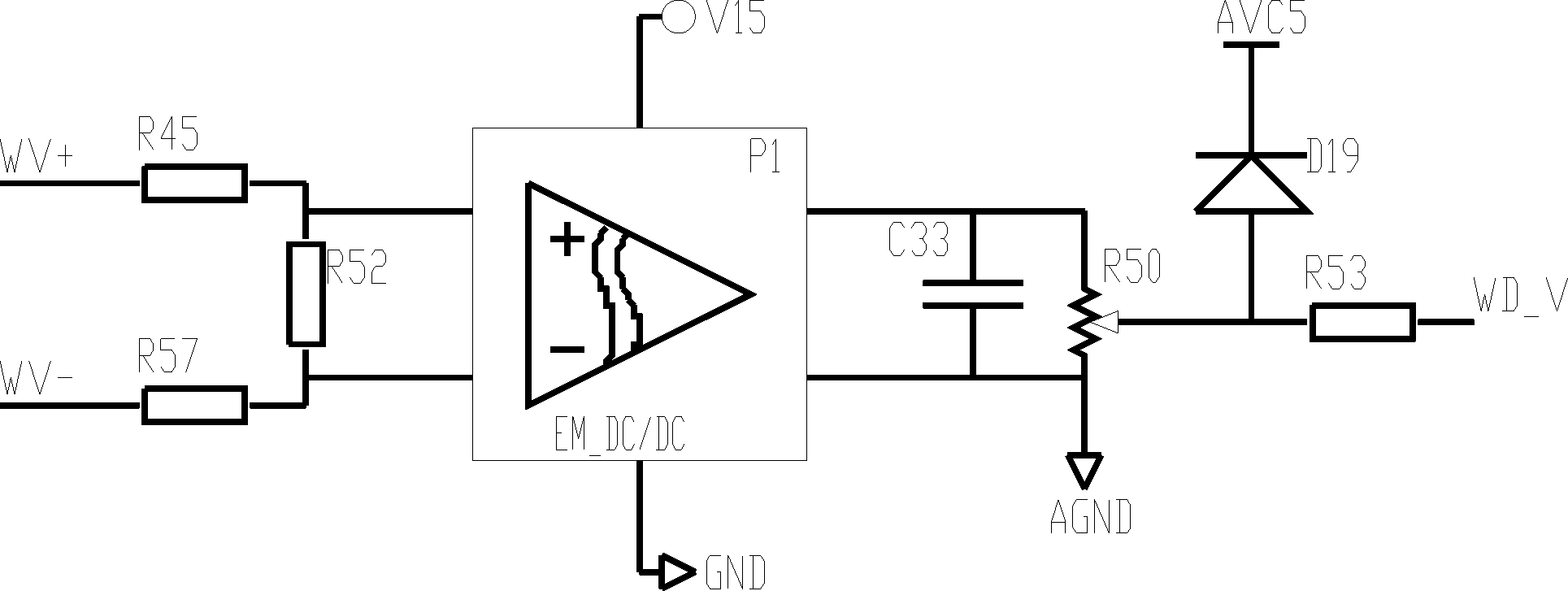

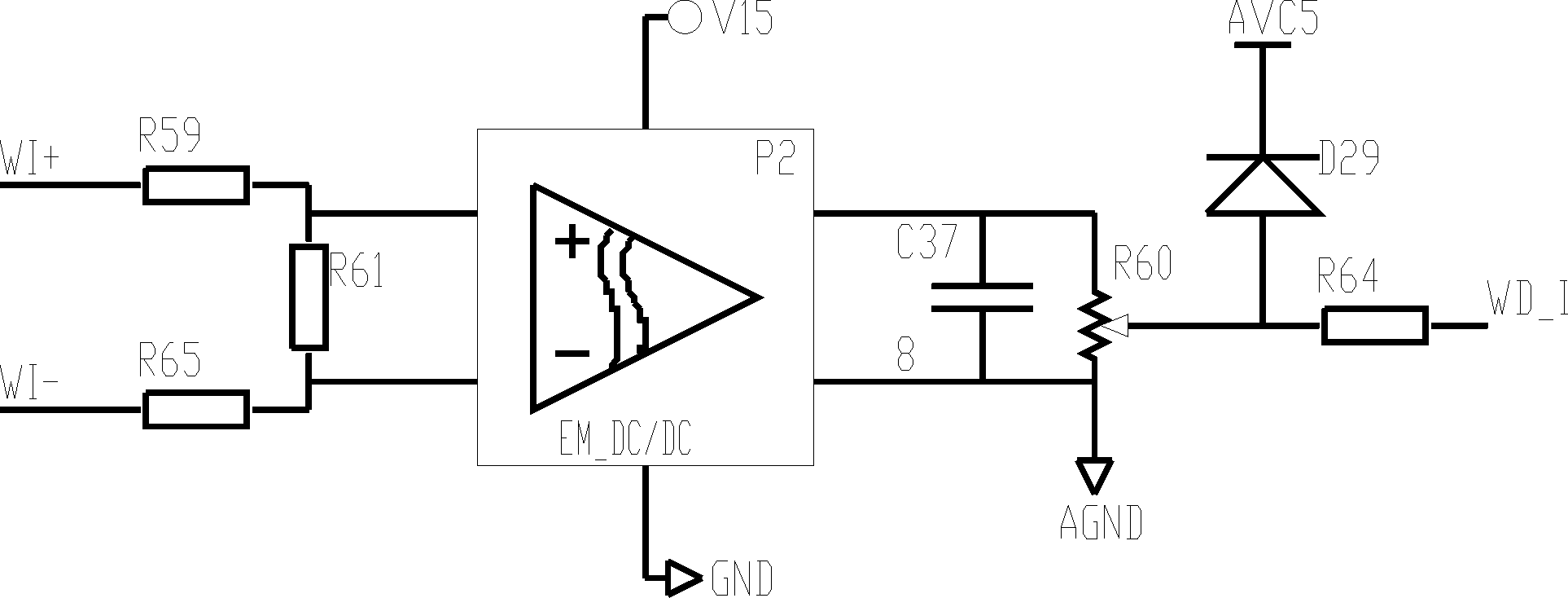

[0033] See figure 1 , a submerged arc welding controller, including a single-chip microcomputer, a welding voltage and current isolation conversion conditioning circuit, a rectifier unit, multiple sets of isolated power supplies, a bus voltage detection unit, a bus voltage adjustment unit, a full-bridge PWM pulse width drive unit, and an armature voltage and current Sampling circuit, motor excitation adjustment unit, power interface.

[0034] The single-chip microcomputer is respectively connected with the bus voltage adjustment unit, the bus voltage detection unit, the full-bridge PWM pulse width drive unit, the armature voltage and current sampling circuit, the motor excitation adjustment unit, and the welding voltage and current isolation conversion conditioning circuit through the power interface, By detecting weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com