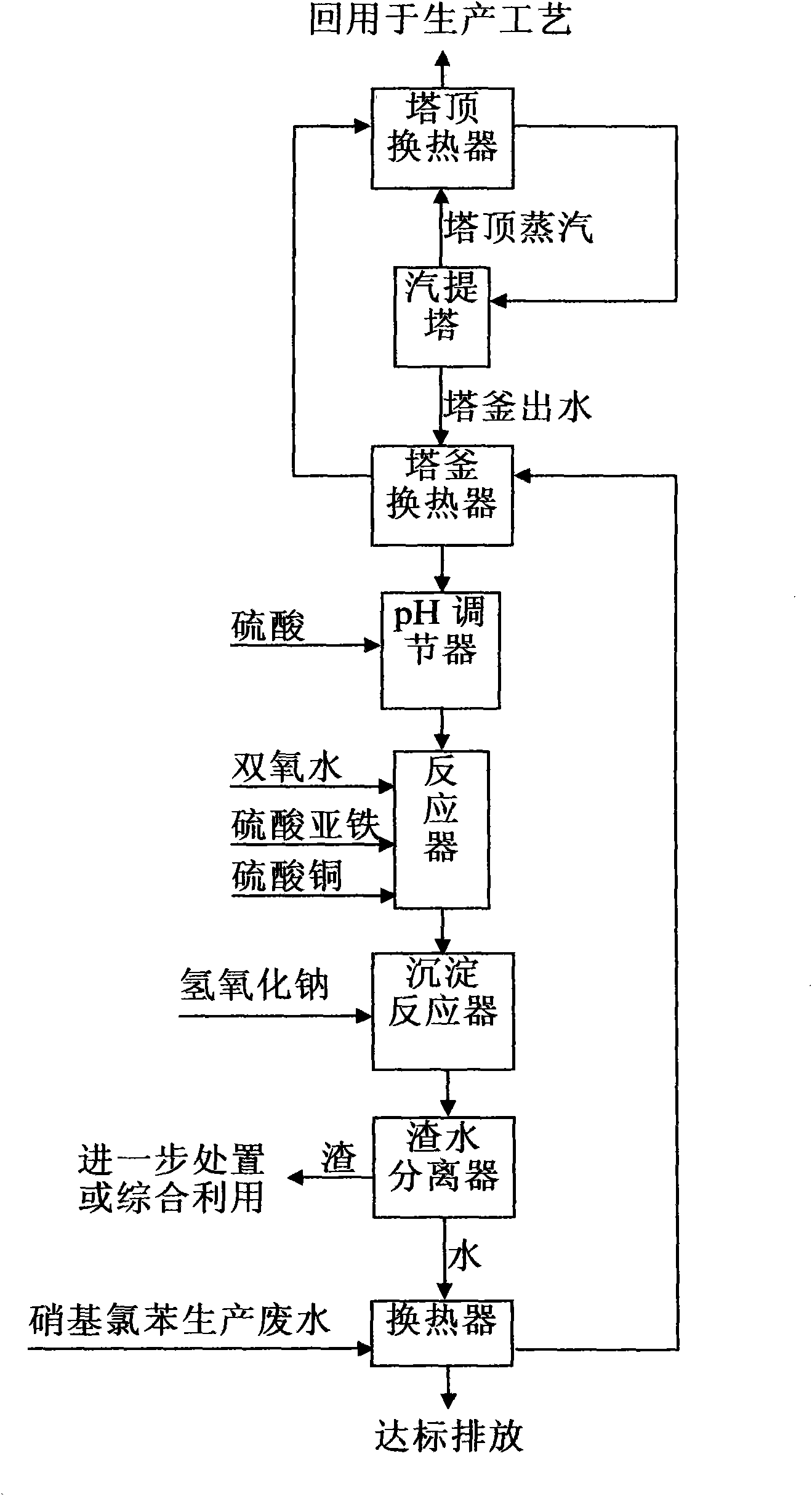

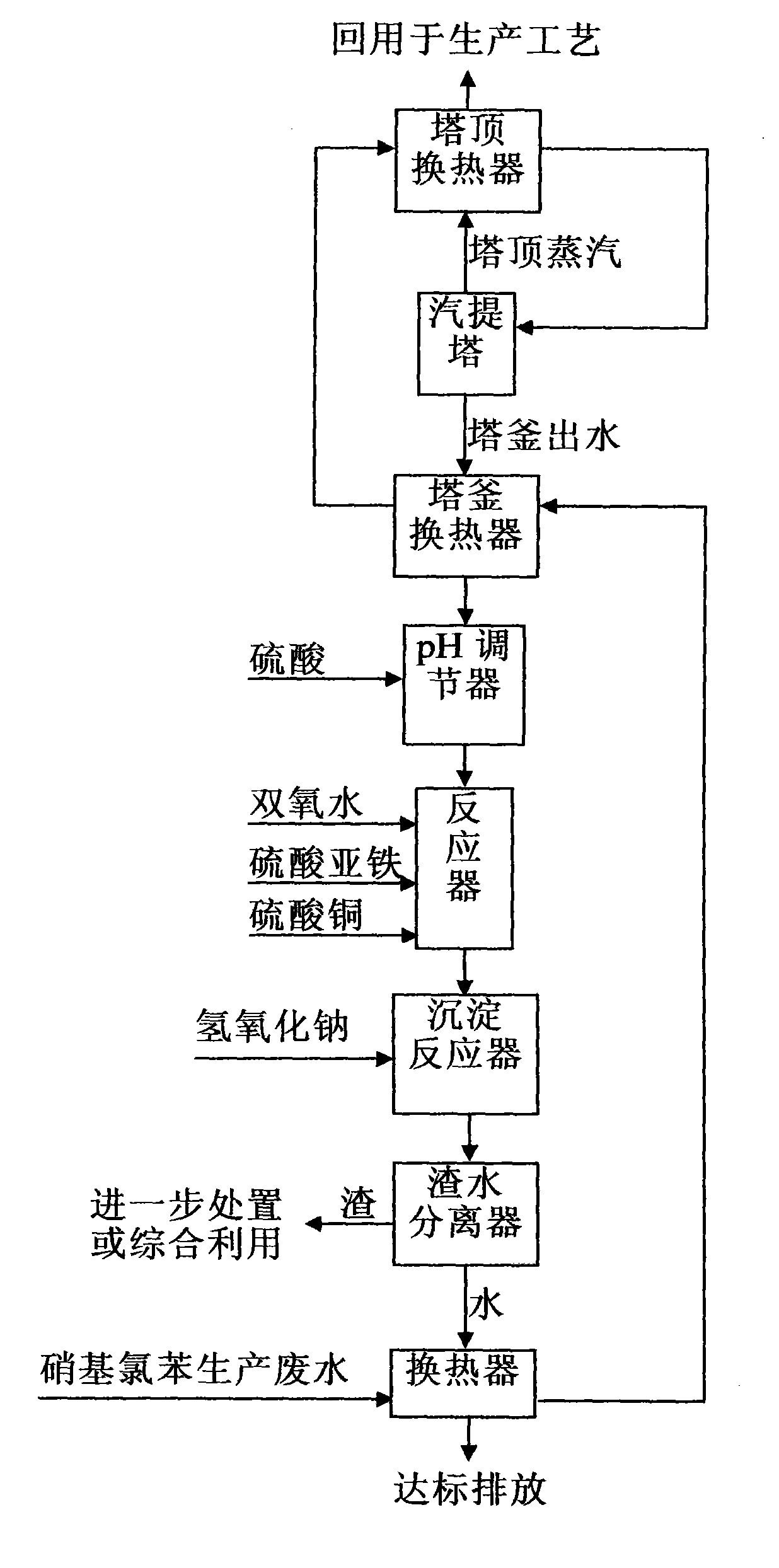

Method for processing wastewater from nitrochlorobenzene production

A technology for the production of waste water and nitrochlorobenzene, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem that nitrochlorobenzene is difficult to meet the discharge standards and lacks complete and effective methods, carbon tetrachloride problems and other problems, to achieve stable and reliable treatment effect, easy industrial scale-up, and improve the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The pH value of nitrochlorobenzene production wastewater in a company is 12.0, the salt content is 2.7%, the content of nitrochlorobenzene is 1180mg / L, and the chroma is 5000 times.

[0029]The temperature in the bottom of the stripper is controlled at 120°C, the pressure (gauge pressure) at the top of the stripper is controlled at 0.08MPa, the theoretical plate number of the stripper is 25, and the outflow of the top of the stripper is 20% of the water entering the tower Under certain conditions, the content of nitrochlorobenzene in the effluent of the stripping tower can be reduced to within 30 mg / L.

[0030] Next, when the temperature of the waste water is 90° C., the pH of the effluent of the stripping tower is adjusted to 2.0 with 5% sulfuric acid.

[0031] Next, the wastewater is subjected to catalytic oxidation treatment, the temperature of the catalytic oxidation reaction system is controlled at 90°C, the pressure is normal pressure, and the amount of 27.5% hydr...

Embodiment 2

[0036] The pH value of nitrochlorobenzene production wastewater from a company is 13.0, the salt content is 2.3%, the content of nitrochlorobenzene is 780mg / L, and the chroma is 4200 times.

[0037] Under the conditions that the temperature of the stripper tower kettle is controlled at 105°C, the pressure at the top of the stripper tower is controlled at normal pressure, the theoretical plate number of the stripper tower is 15, and the outflow of the tower top of the stripper tower is 8% of the water entering the tower, The content of nitrochlorobenzene in the effluent of the stripping tower can be reduced to less than 100 mg / L.

[0038] Next, when the temperature of the waste water is 85° C., the pH of the effluent of the stripping tower is adjusted to 2.5 with 5% sulfuric acid.

[0039] Next, carry out catalytic oxidation treatment to waste water, the temperature control of catalytic oxidation reaction system is 85 ℃, the pressure is normal pressure, the dosage of 27.5% hydr...

Embodiment 3

[0044] The pH value of nitrochlorobenzene production wastewater from a company is 13.0, the salt content is 2.3%, the content of nitrochlorobenzene is 780mg / L, and the chroma is 4200 times.

[0045] Under the conditions that the temperature of the stripper tower kettle is controlled at 105°C, the pressure at the top of the stripper tower is controlled at normal pressure, the theoretical plate number of the stripper tower is 15, and the outflow of the tower top of the stripper tower is 8% of the water entering the tower, The content of nitrochlorobenzene in the effluent of the stripping tower can be reduced to less than 100 mg / L.

[0046] Next, when the temperature of the waste water is 85° C., the pH of the effluent of the stripping tower is adjusted to 4.0 with 5% sulfuric acid.

[0047] Next, carry out catalytic oxidation treatment to waste water, the temperature control of catalytic oxidation reaction system is 85 ℃, the pressure is normal pressure, the dosage of 27.5% hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com