High tensile strength multicomponent mixed inclusion PVB (polyvinyl butyral) diaphragm and production method thereof

A high tensile strength, multi-component technology, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, adhesive types, etc., can solve low tensile strength, low elongation at break, etc. problem, achieve the effects of improving dispersion performance, improving tensile strength, good shielding and negative ion release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

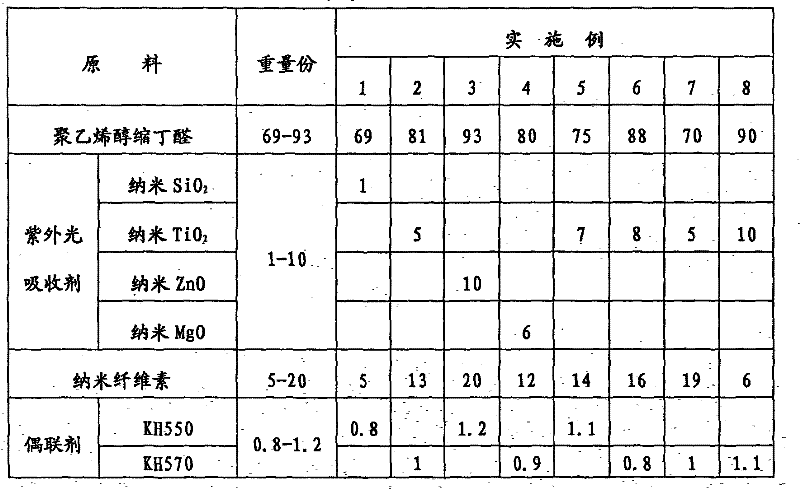

[0018] Embodiment 1 (compared with the raw material of Table 1 Embodiment 1 and the proportioning value by weight): 5 parts of nanocellulose, 1 part of nano-SiO 2 , 0.8 parts of KH550 type γ-aminopropyltriethoxysilane (referred to as KH550 coupling agent) is added to 69 parts of polyvinyl butyral (PVB), fully stirred in the cone mixer, and sent through the feeder Put it into a twin-screw extruder, heat it to 145°C for mixing and extrusion, and extrude and cast it through a die to make a multi-component PVB diaphragm with a thickness of 0.39mm (abbreviated as this diaphragm) ).

[0019] All the other embodiments 2-8 are compared with the raw materials and weight ratios of the corresponding examples in Table 1, and the diaphragm is made in the same way as in Example 1. Considering the comprehensive performance of the diaphragm, examples 6 and 7 are used. preferred.

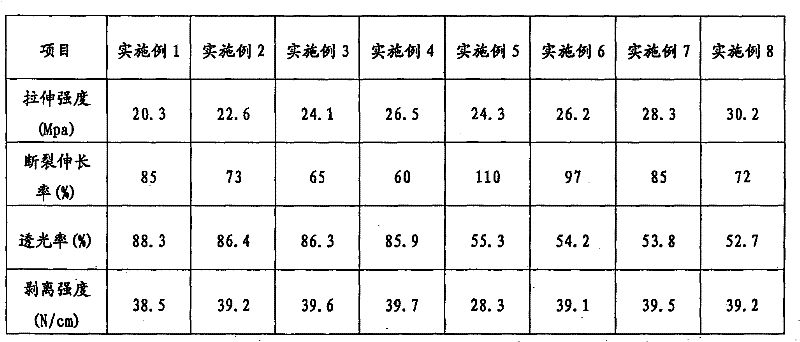

[0020] Now this diaphragm test performance that is made by embodiment 1-8 is introduced in table 2:

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com