Infrared camouflage paint and preparation method thereof

A stealth coating and infrared technology, which is applied in the field of polymer composite material preparation, can solve the problems of coating limitation, poor coating tolerance, increased emissivity, etc., and achieve improved processing performance, improved stability, and enhanced heat transfer performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

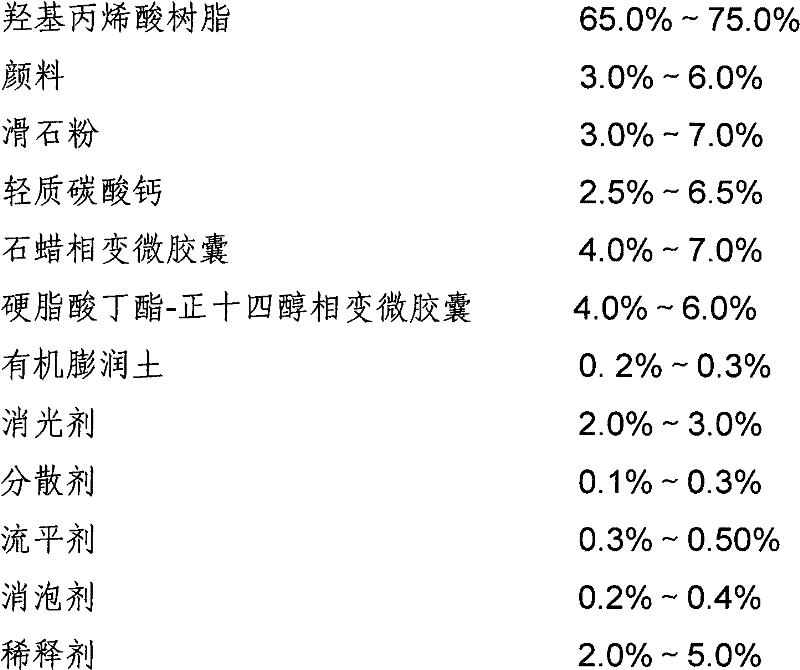

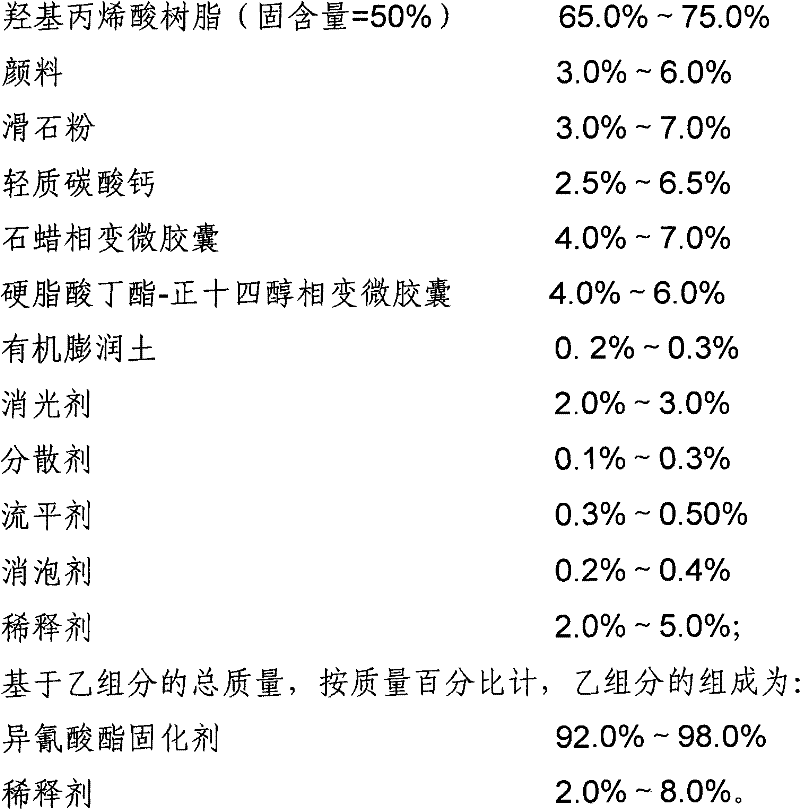

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of infrared stealth coating, carries out batching according to above-mentioned components, and its steps are:

[0052] (1) The preparation steps of melamine-formaldehyde prepolymer are:

[0053] Add the formulated amount of melamine, formaldehyde and deionized water into the four-necked bottle equipped with electric stirring, condenser, thermometer, feeding port and water bath heating in sequence, and the water bath is heated to 75 ° C. After the bulk material system is transparent, use 10% Triethanolamine aqueous solution is adjusted to pH = 8-9, and then reacted at a constant temperature for 30 minutes to prepare a melamine-formaldehyde prepolymer, which is discharged and set aside;

[0054] (2) The preparation steps of paraffin core material emulsion are:

[0055] ① Add the deionized water and emulsifier 2 in the prescribed amount into a three-port container equipped with a thermometer, mechanical stirring and condensing device, heat the water...

Embodiment 1

[0069] The preparation of embodiment 1.MF prepolymer

[0070] Add 20.2g of melamine, 38.9g of 37% formaldehyde and 110.4g of deionized water into a four-neck bottle equipped with electric stirring, condenser, thermometer, feeding port and water bath heating in sequence, and heat the water bath to 75°C. After the material system becomes transparent , use 10% triethanolamine aqueous solution to adjust pH=8-9, then react at constant temperature for 30 minutes to prepare MF prepolymer, discharge and set aside.

Embodiment 2

[0071] Embodiment 2. The preparation of core material emulsion

[0072] (1) Preparation of paraffin core material emulsion

[0073] ①Add 164.0g of deionized water and 13.6g of emulsifier op-10 into a three-port container equipped with a thermometer, mechanical stirring and condensing device, heat the water bath to 65°C, stir at 300-400r / min for 20min, and obtain an emulsifier aqueous solution , discharge, and set aside; ②Add 40g of paraffin and 2.4g of emulsifier span-80 into the emulsification reactor, heat and melt and stir at 1000r / min, stop heating and keep warm when the material reaches 65°C, and continue stirring for 20min; ③In At a stirring speed of 1000r / min, divide the emulsifier aqueous solution into 5 parts and add them to the emulsification reactor in batches, with an interval of 5 minutes each time. After the last batch of emulsifier aqueous solution is added, directly adjust the stirring speed to 4000r / min and stir for 40 minutes. Prepare paraffin wax emulsion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com