Antistatic polysulfonamide/carbon nano-tube composite material and preparation method thereof

A polysulfone amide and carbon nanotube technology, which is used in the manufacture of conductive/antistatic filaments, single-component copolyamide rayon, etc., can solve the problem of nanotechnology polysulfone amide/carbon nanotube composite materials. , The problems of composite materials of polysulfone amide and nanoparticles are rarely seen, and the effects of excellent high temperature dimensional stability, low cost and strong operability are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

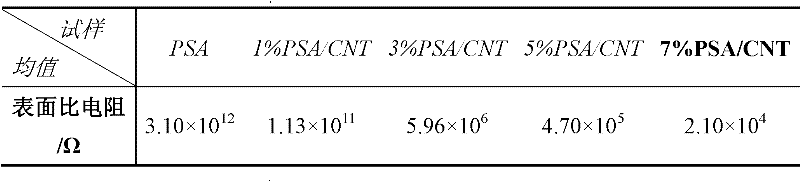

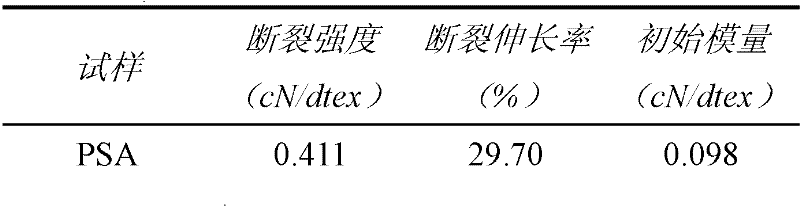

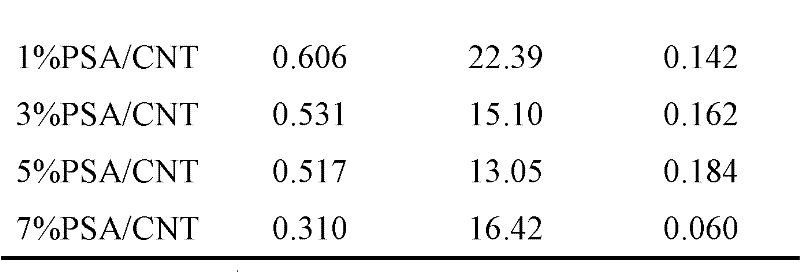

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of polysulfone amide / carbon nanotube composite fiber

[0029] Specific steps are as follows:

[0030] 1) Preparation of carbon nanotube solvent dispersion:

[0031] Weigh 0.12 g of carbon nanotubes and disperse them in 3 mL of dimethylacetamide solvent; the above solvent dispersion is subjected to ultrasonic blending treatment for 60 min to uniformly disperse the carbon nanotubes in the dimethylacetamide solvent to form a Dispersive carbon nanotube solvent dispersion;

[0032] 2) Weigh 100g of polysulfone amide spinning solution, add the above-mentioned carbon nanotube solvent dispersion into the conical flask, carry out shearing mechanical stirring at a speed of 10000r / min for 30min, and then under the ultrasonic frequency of 30-40KHz Ultrasonic blending was carried out for 90 minutes to prepare polysulfoneamide / carbon nanotube composite spinning solution;

[0033] 3) Wet spinning is carried out by using a single-hole small wet spinning dev...

Embodiment 2

[0040] Embodiment 2: Preparation of polysulfone amide / carbon nanotube composite film

[0041] The polysulfone amide nanocomposite film was prepared by using the SJT-B desktop digital display homogenizer, and the specific steps are as follows:

[0042] 1) Set the film-making conditions of the instrument: 2000RPM low-speed operation for 5s and 4000RPM high-speed operation for 20s;

[0043] 2) Take an appropriate amount of the composite material spinning solution obtained in Example 1, put it on the substrate in the glue leveling table after standing for defoaming, and first run at a low speed of 2000RPM for 5s to spread the spinning solution with the number of revolutions per minute;

[0044] 3) After the set time, it will automatically switch to a high-speed operation with a revolution per minute of 4000RPM for 20s to make the spinning solution form a film with uniform thickness on the substrate;

[0045] 4) Place the substrate in the air for 30 minutes to evaporate the solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com