Organic field effect transistor with dielectric modification layer and preparation method thereof

An organic field and transistor technology, applied in the field of organic field effect transistors and its preparation, can solve problems such as shortage, uncertainty of the number of hydroxyl groups on the surface of the dielectric layer, uneven distribution, etc., achieve a small threshold voltage, overcome the uncertainty of bonding effects of inhomogeneity and distribution inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

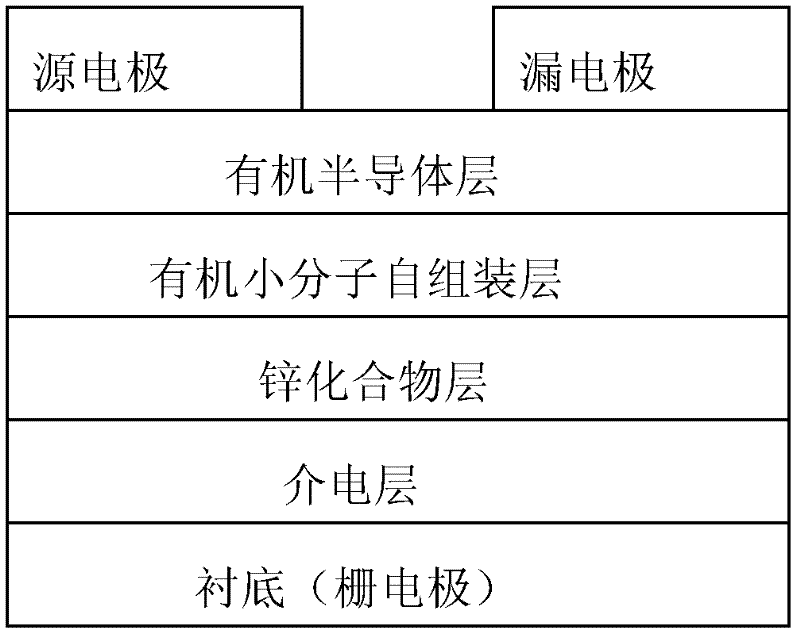

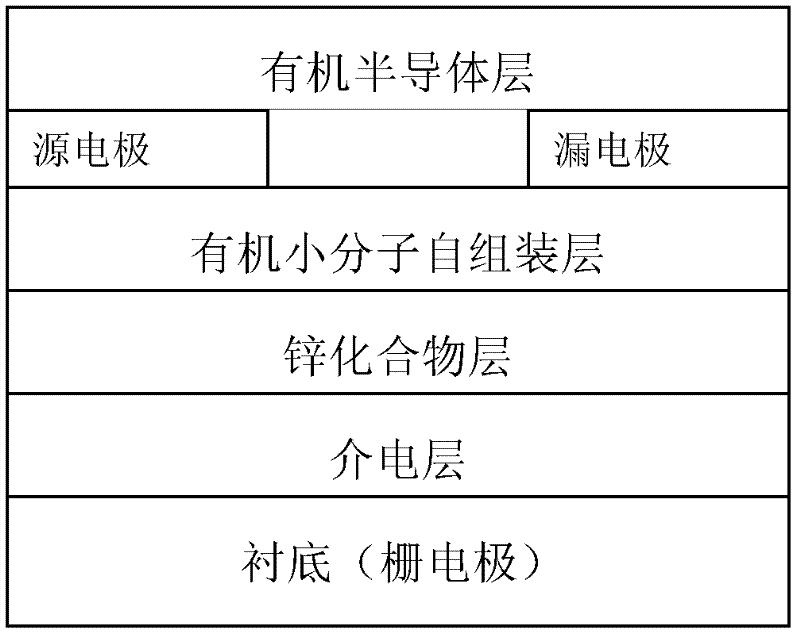

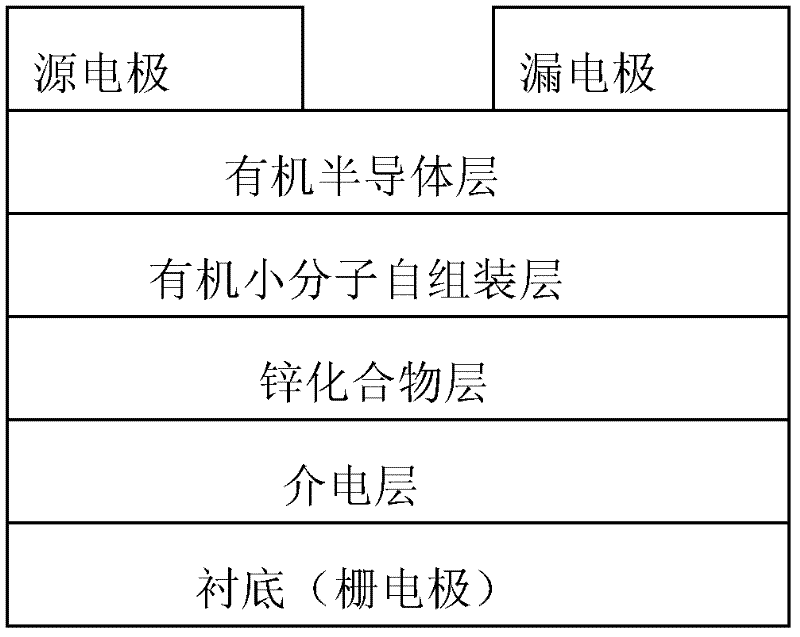

Method used

Image

Examples

Embodiment 1

[0038] Implementation steps:

[0039] Step 1: Cleaning of Silicon Substrate

[0040] will have SiO 2 (thickness is 303 nanometers) n-type heavily doped silicon substrate (resistivity 0.02—0.04Ωcm) of the dielectric layer is ultrasonically cleaned with detergent, tap water, deionized water, acetone, and absolute ethanol for 5 minutes, and then placed Dry in oven.

[0041] Step 2: Deposition of Zinc Compound Layer

[0042] Spin-coat a solution of diethylzinc in cyclohexanone (concentration: 0.01 M) on the above-mentioned silicon substrate, so that the SiO 2 A zinc compound layer is formed on the surface with a thickness of 30 nm.

[0043] The third step: annealing treatment of the zinc compound layer

[0044] The silicon wafer deposited with the zinc compound was placed in an oven, and annealed at 180° C. for 15 minutes in the atmosphere.

[0045] Step 4: Deposition of organic small molecule self-assembled layer

[0046] OTMOS trichlorethylene solution (concentration: 3 m...

Embodiment 2

[0059] The device was prepared according to the method of Example 1, except that poly(3-hexylthiophene) was selected as the organic semiconductor material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com