Wide-temperature range low-loss Mn-Zn ferrite and its preparation method

A low-loss, ferrite technology, applied in the preparation of the ferrite, in the field of manganese-zinc ferrite with wide temperature and low loss, can solve the problems of high cost and large amount of cobalt oxide added, and achieve good formability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

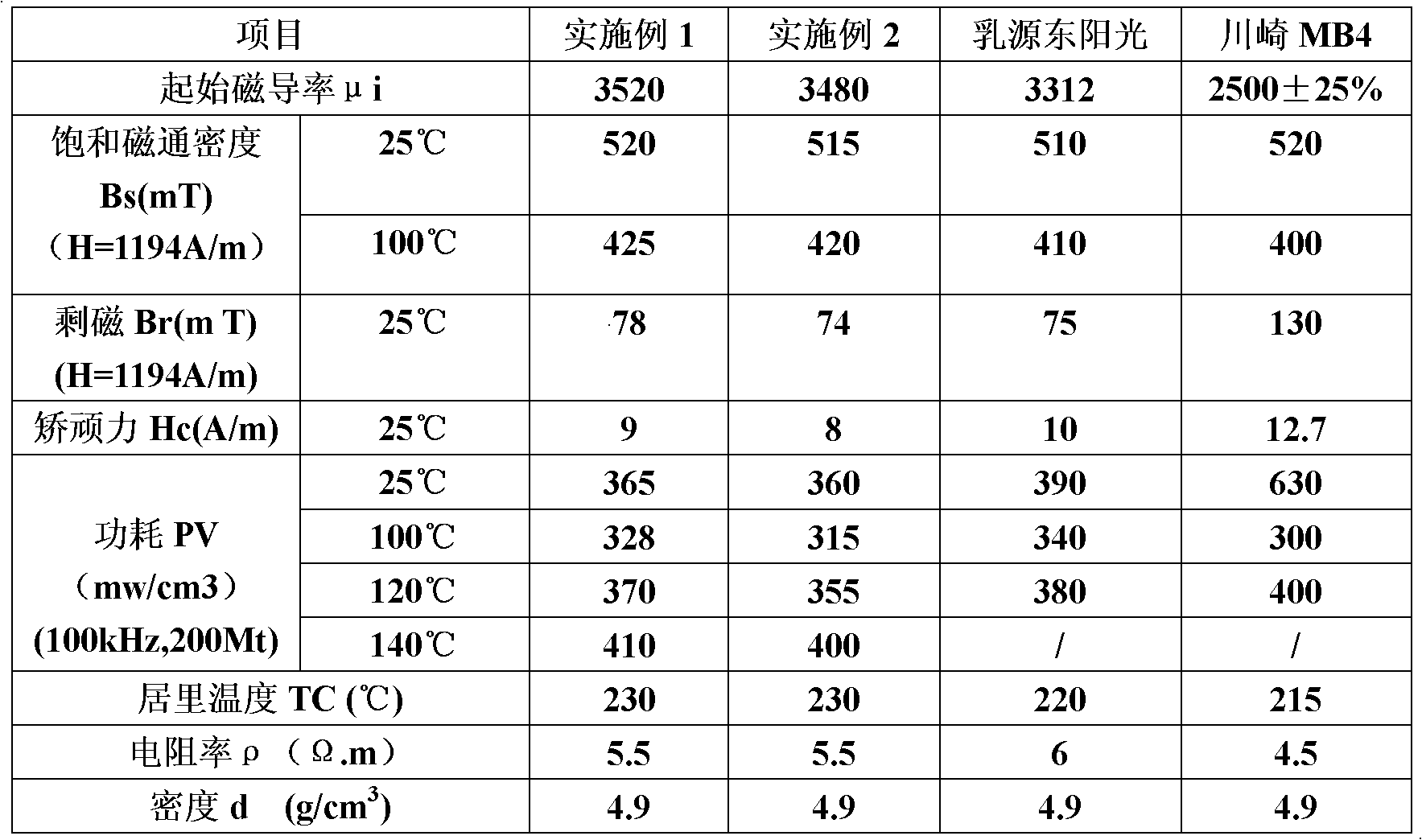

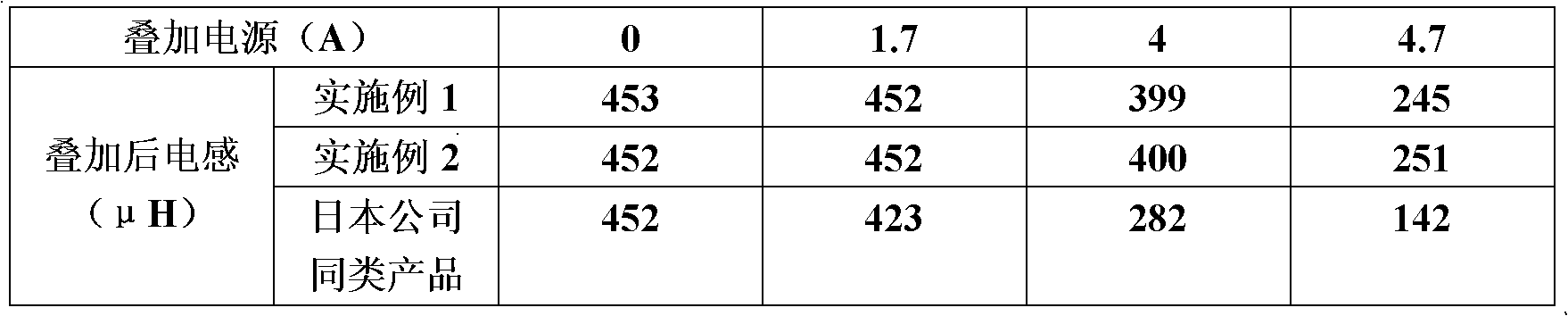

Examples

Embodiment 1

[0025] A) Weigh 54.2mol% Fe2 o 3 , 39.45mol% of MnO and 6.35mol% of ZnO, wherein the raw material of MnO is Mn 3 o 4 , using the grade CR-06 sold by Hunan Jinrui Technology Co., Ltd. in Hunan Province, China, with a purity of Mn% ≥ 71%, Fe 2 o 3 Domestic Shanghai Baosteel is used with a purity of Fe2O3% ≥ 99.3%. ZnO is produced and sold by Shanghai Jinghua Chemical Factory, and its weight percentage content is ZnO% ≥ 99.7%. The above three raw materials are mixed in proportion and put into a vibration mill Vibration milling is carried out in the medium, and the average particle size is controlled to be 0.95±0.20 μm to obtain the main component powder;

[0026] B) The main component powder obtained in step A) is vibrated and ground to meet the process requirements, then granulated and dried, and then pre-fired with an electric rotary kiln at a temperature of 870±30°C. After the pre-burning is completed, put the pre-fired material into Circulating sand milling is carried out...

Embodiment 2

[0032] A) Weigh 54.1mol% Fe 2 o 3 , 38.95mol% of MnO and 6.85mol% of ZnO, wherein the raw material of MnO is Mn 3 o 4 , using Hunan Jinrui CR-06, its purity Mn% ≥ 71%, Fe2O3 using domestic Shanghai Baosteel, its purity Fe 2 o 3 % ≥ 99.3%, ZnO uses Shanghai Jinghua, and its weight percentage content ZnO% ≥ 99.7%. After mixing the above three raw materials in proportion, they are put into a vibration mill for vibration grinding, and the average particle size is controlled to be 0.95±0.20μm. Obtain the main component powder;

[0033] B) The main component powder obtained in step A) is vibrated and ground to meet the process requirements, then granulated and dried, and then pre-fired in an electric rotary kiln at a temperature of 870±30°C. After the pre-burning is completed, the pre-fired material is put into sand Circulating sand milling is carried out in the mill. During the process of circulating sand milling, pure water, dispersant, defoamer, PVA are added, and auxiliary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Corner of repose | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com