Low temperature soaping powder and preparation method thereof

A low-temperature soaping and washing powder technology, which is applied in the preparation of detergent mixture compositions, chemical instruments and methods, dyeing methods, etc., can solve the problem of inability to prepare soaping agent or soaping powder, rarely consider the chromaticity of residual liquid, It does not have problems such as oxidation and decomposition, and achieves excellent cleaning function, anti-staining ability, good decolorization function, and remarkable effect of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The low-temperature soaping powder in this embodiment is composed of horse-acrylic copolymer powder, sodium percarbonate and sodium perborate, wherein the particle diameter of the horse-acrylic copolymer powder is between 0.1-1 mm.

[0028] In the low-temperature soaping powder of the present embodiment, the parts by weight of the horse-acrylic copolymer powder are 25-65 parts, the parts by weight of sodium percarbonate are 35-85 parts, and the parts by weight of sodium perborate are 35-85 parts . In the low-temperature soaping powder of the present invention, the parts by weight of the horse-acrylic copolymer powder can be 25 parts, 26 parts, 28 parts, 30 parts, 32 parts, 34 parts, 36 parts, 38 parts, 40 parts, 42 parts , 44 parts, 46 parts, 48 parts, 50 parts, 52 parts, 54 parts, 56 parts, 58 parts, 60 parts, 62 parts, 64 parts or 65 parts, the parts by weight of sodium percarbonate can be 35 parts, 36 parts parts, 38 parts, 40 parts, 44 parts, 46 parts, 48 parts...

Embodiment 2

[0042] see Figure 1 to Figure 2 , the method for preparing low-temperature soaping powder in this embodiment is to first place the aqueous solution of horse-acrylic copolymer with a solid content of 40% in the reaction kettle, start the stirrer, and simultaneously steam heating and vacuum, and raise the temperature to 75°C Vacuum distillation for 5 hours, then turn on the jacket water to cool down to 60°C and maintain this temperature, discharge the material, then place it in a vacuum oven, dry it in vacuum at a temperature of 110°C for 10 hours, take it out and pulverize it to obtain a horse-propylene copolymer powder. Then take 50 parts by weight of sodium percarbonate, 30 parts of sodium perborate and 20 parts of horse-acrylic copolymer powder and place them in a powdery stirring tank in turn, stir for 20 minutes, and discharge to get low-temperature soaping powder .

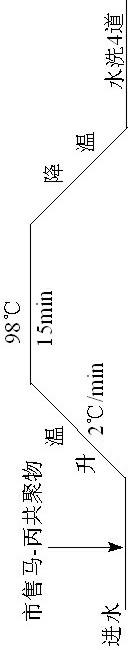

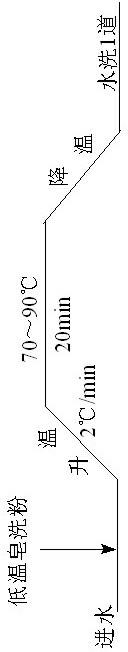

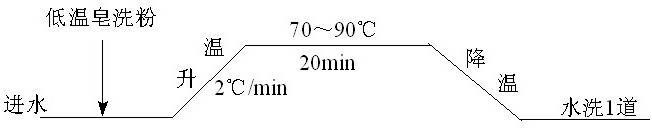

[0043] In order to more clearly illustrate that the low-temperature soaping powder prepared by the pres...

Embodiment 3

[0048] The method for preparing low-temperature soaping powder in this example is to first place the horse-acrylic copolymer solution with a solid content of 50% in the reaction kettle, start the stirrer, heat with steam and turn on the vacuum, and then heat up to 80°C for vacuum distillation After 4 hours, start the jacket water to cool down to 60°C and maintain this temperature, discharge the material, then place it in a vacuum oven, dry it in vacuum at 115°C for 9 hours, take it out and pulverize it to obtain a horse-acrylic copolymer powder. Then take by weight 60 parts of sodium percarbonate, 25 parts of sodium perborate and 15 parts of horse-acrylic copolymer powder and place them in a stirring tank in sequence, stir for 20 minutes, and discharge to obtain low-temperature soaping powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com