Electrical contact material and method for preparing CuZrW electrical contact material by adopting infiltration method

An electric contact material and infiltration technology, applied in the direction of contacts, circuits, electric switches, etc., can solve problems such as electrical breakdown, and achieve the effect of improving arc ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

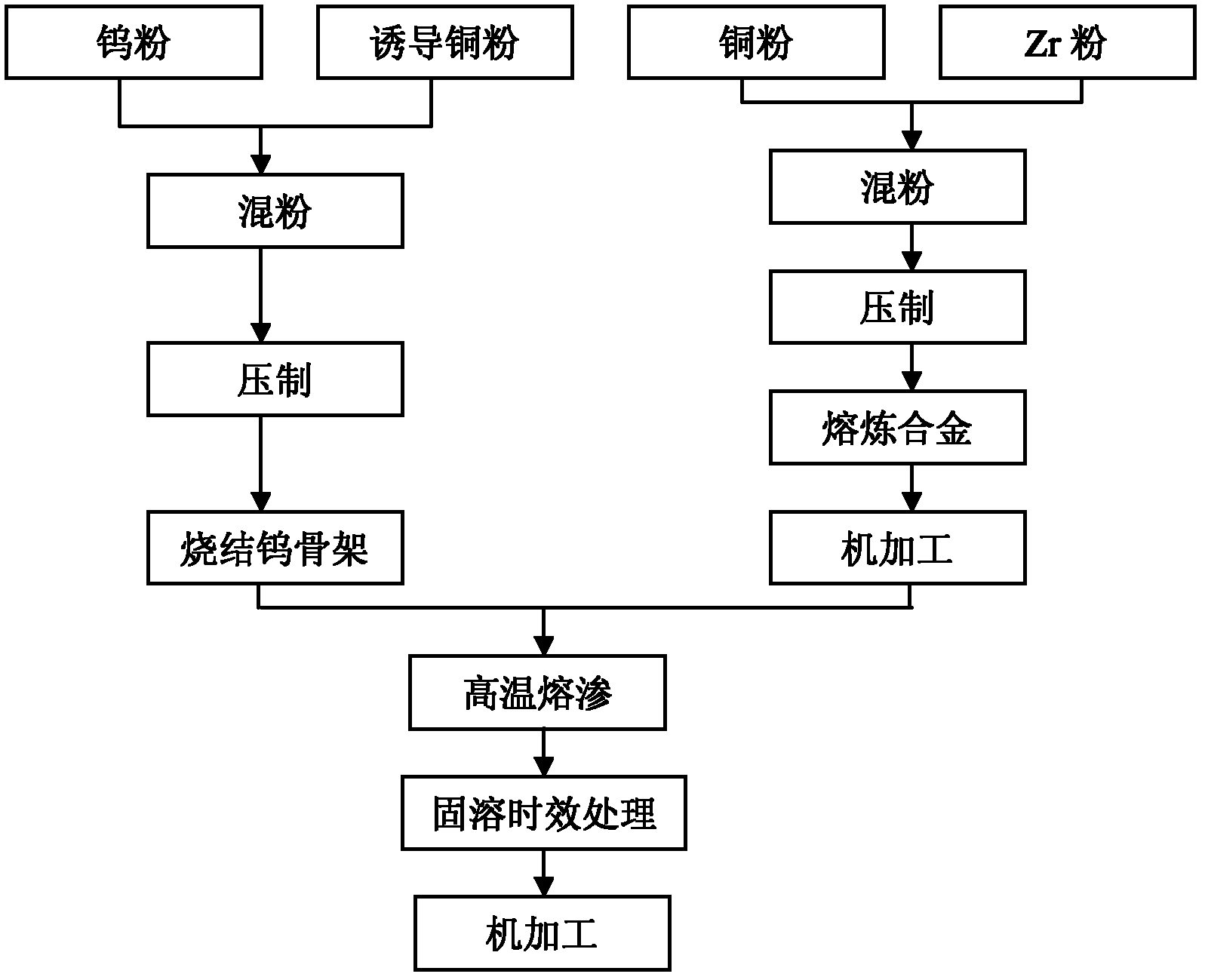

[0030] The preparation method of CuZrW electrical contact material of the present invention, carry out according to the following steps,

[0031] Preparation of CuZr Alloy Ingot

[0032] a. Take electrolytic copper powder with a purity of not less than 99.9% and Zr powder with a purity of not less than 99%. Zr accounts for 1 to 4.0 wt% of copper by weight. Pressed into a green body in the mold;

[0033] b. Put the green body obtained in step a into a corundum crucible, put it in an argon atmosphere furnace for melting, the melting temperature is 1150-1300°C, keep it warm for 0.5-2 hours and then cool it down to room temperature with the furnace to prepare CuZr alloy Ingot;

[0034] c. the CuZr alloy ingot made by step b is removed by machining to remove various defects on the alloy ingot, and cleaned;

[0035] Preparation of tungsten compacts

[0036] a. Take tungsten powder and induced copper powder respectively. The induced copper powder accounts for 5-8% of the mass of ...

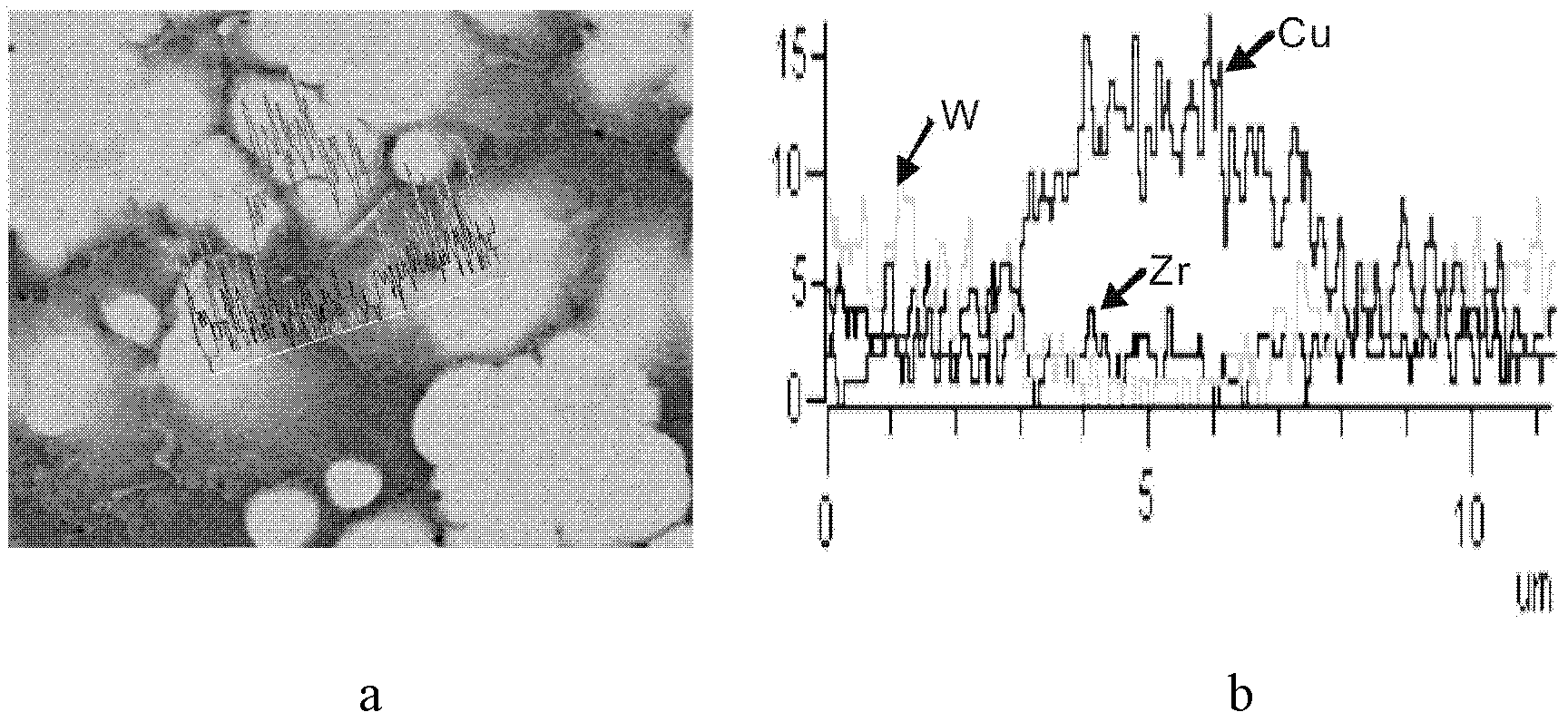

Embodiment 1

[0044] First prepare CuZr alloy ingots, respectively take electrolytic copper powder with a purity of not less than 99.9% and Zr powder with a purity of not less than 99%, the mass percentage of Zr in copper is 4.0wt.%, and fully mix the copper powder and Zr powder Finally, press into a green body in a rigid mold; put the prepared green body into a corundum crucible, put it in an argon atmosphere furnace for melting, the melting temperature is 1150°C, keep it warm for 0.5 hours, and then cool it to room temperature with the furnace. Obtain a CuZr alloy ingot; remove various defects on the alloy ingot by machining the obtained CuZr alloy ingot, and clean it;

[0045] Then prepare the tungsten compact, take the tungsten powder and the induced copper powder respectively, the induced copper powder accounts for 6% of the mass of the tungsten powder, put the tungsten powder and the induced copper powder into the mixing tank, add the grinding ball and the mixing process control agent,...

Embodiment 2

[0048] First prepare CuZr alloy ingots, respectively take electrolytic copper powder with a purity of not less than 99.9% and Zr powder with a purity of not less than 99%, and the mass percentage of Zr in copper is 2.0wt.%. Copper powder and Zr powder are fully mixed Finally, press into a green body in a rigid mold; put the prepared green body into a corundum crucible and put it in an argon atmosphere furnace for melting. Obtain a CuZr alloy ingot; remove various defects on the alloy ingot by machining the obtained CuZr alloy ingot, and clean it;

[0049] Then prepare the tungsten compact, take the tungsten powder and the induced copper powder respectively, the induced copper powder accounts for 5% of the mass of the tungsten powder, put the tungsten powder and the induced copper powder into the mixing tank, add the grinding ball and the mixing process control agent, The mass of the added grinding ball is 3 times of the total mass of the tungsten powder and the copper powder, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com