Method and device for the spectral analysis of a metal coating layer deposited on the surface of a steel strip

A metal coating and spectral analysis technology, applied in the field of spectral analysis of metal coatings, can solve problems such as exceeding the compensation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

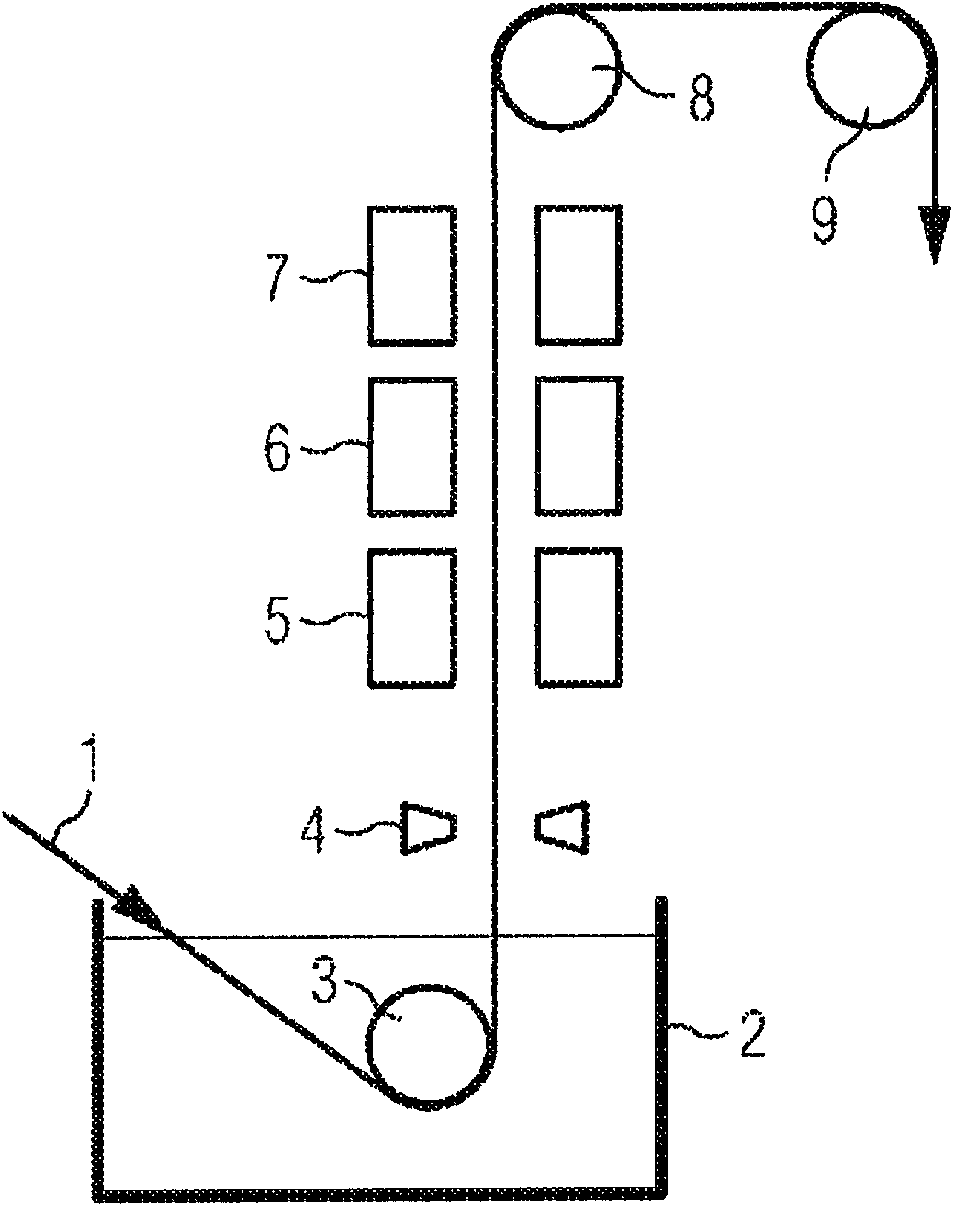

[0062] figure 1 General scheme representing quench plating of a steel strip 1 in motion: A steel strip 1 from an electroplating kiln is immersed in a liquid plating bath 2 and deflected vertically with a roller 3 submerged in the bath. The steel strip then sequentially passes through the dehydration device of the liquid film 4, enters the induction heating device 5, enters the device 6 for maintaining the alloying temperature, and the cooling device 7, where the coating film is solidified. The strip is then partly wound around first deflection rolls 8 and second rolls 9 before continuing with the converting operation and recoiling into galvanized steel coils.

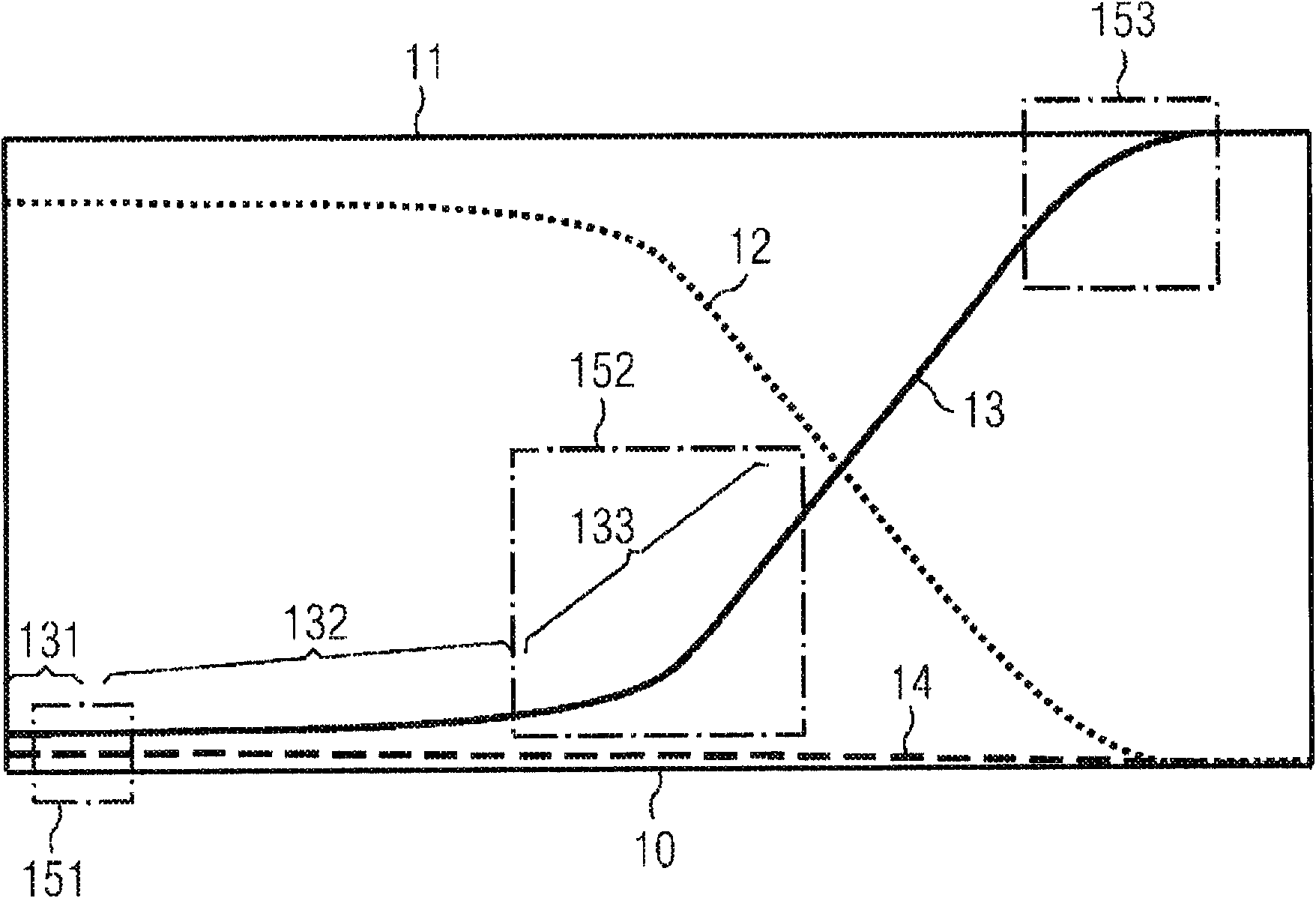

[0063] figure 2 As an example, a graph representing the variation of zinc, iron and aluminum concentrations in a GA-type coating: the abscissa axis (x-axis) 10 represents the variation in depth in the coating whose surface is at a distance from the ordinate axis (y-axis) 11 At the intersection point of , which repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com