Method for processing opening shelled macadimia nut

A processing method and technology of nuts, applied in the fields of application, food preparation, food science, etc., can solve the problems of difficulty in meeting the multi-level consumption needs of the public, high price, single eating form, etc., and achieve the expansion of the consumer market, eating convenience, and flavor unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

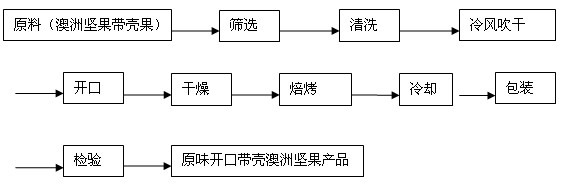

Embodiment 1

[0018] (1) Screening: screen out the inferior fruits such as insect-infested fruit, moldy fruit, germinated fruit and immature fruit in shelled macadamia nuts;

[0019] (2) Cleaning: Use tap water to clean the dust, soil and other sundries on the surface of macadamia nuts in shell, and remove floating fruit, so as not to affect product quality;

[0020] (3) Drying with cold air: Use an electric hot air drying box to dry the surface water of macadamia nuts with cold air at a temperature of 20-30°C;

[0021] (4) Opening: Shelled macadamia nuts are opened on the opening machine (when opening, use the upper knife edge to align with the suture line of the macadamia nut, and use even force);

[0022] (5) Drying and baking: Put the open shelled macadamia nuts into an electric hot air drying oven, dry at 40°C for 6 hours, dry at 60°C for 12 hours, and continue to heat up to 125°C for 8 minutes;

[0023] (6) Cooling, packaging, and inspection; the original open-shelled macadamia nut p...

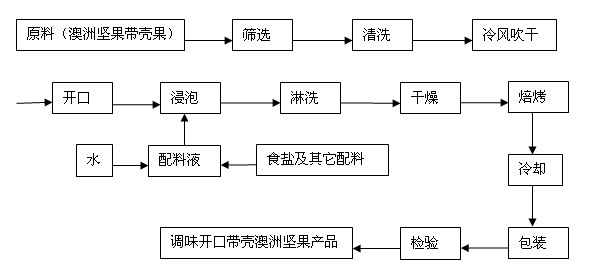

Embodiment 2

[0025] (1) Screening: screening out insect-infested fruit, moldy fruit, germinated fruit and immature fruit and other inferior fruits in shelled macadamia nuts;

[0026] (2) Cleaning: Use tap water to clean the dust, soil and other sundries on the surface of macadamia nuts in shell, and remove floating fruit, so as not to affect product quality;

[0027] (3) Drying with cold air: Use an electric hot air drying box to dry the surface water of macadamia nuts with cold air at a temperature of 20-30°C;

[0028] (4) Opening: Shelled macadamia nuts are opened on the opening machine (when opening, use the upper knife edge to align with the suture line of the macadamia nut, and use even force);

[0029] (5) Soaking: Use 24% salt and the rest as water to configure the batching solution, and add the open shelled macadamia nuts to soak according to the ratio of the volume of the batching solution (L) to the weight of the open nuts (kg) 1:1, stir evenly, and Stir once every 0.5h, soak fo...

Embodiment 3

[0034] Steps (1)-(4) are the same as in Example 2;

[0035] (5) Soaking: According to 20% salt + 18% white sugar + 0.8% monosodium glutamate + 0.8% vanillin, the rest is water, prepare the batching liquid, according to the volume of the batching liquid (L) and the weight (kg) of open nuts 1: Add open shelled macadamia nuts at a ratio of 1, stir evenly, stir once every 0.5h, soak for 2h;

[0036] (6) Spray: Spray and rinse the soaked open shelled macadamia nuts with tap water to remove the salt and other ingredients on the surface and cracks;

[0037] (7) Drying and baking: Put the soaked open-shell macadamia nuts into an electric hot air drying oven, dry at 60°C for 4 hours, and dry at 80°C for 6 hours, so that the water content of the open-shell macadamia nuts drops below 1.5%, and continue Bake at 120°C for 10 minutes;

[0038] (8) Cooling, packaging, and inspection; the finished product of sweet-flavored and shelled macadamia nuts is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com