Tissue engineering bone cartilage composite bracket and integrated photocuringable forming method thereof

A technology of photocuring molding and tissue engineering bone, which is applied in the fields of prosthesis and medical science, and can solve the problems of poor bonding force, low degree of automation and customization, and complicated operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

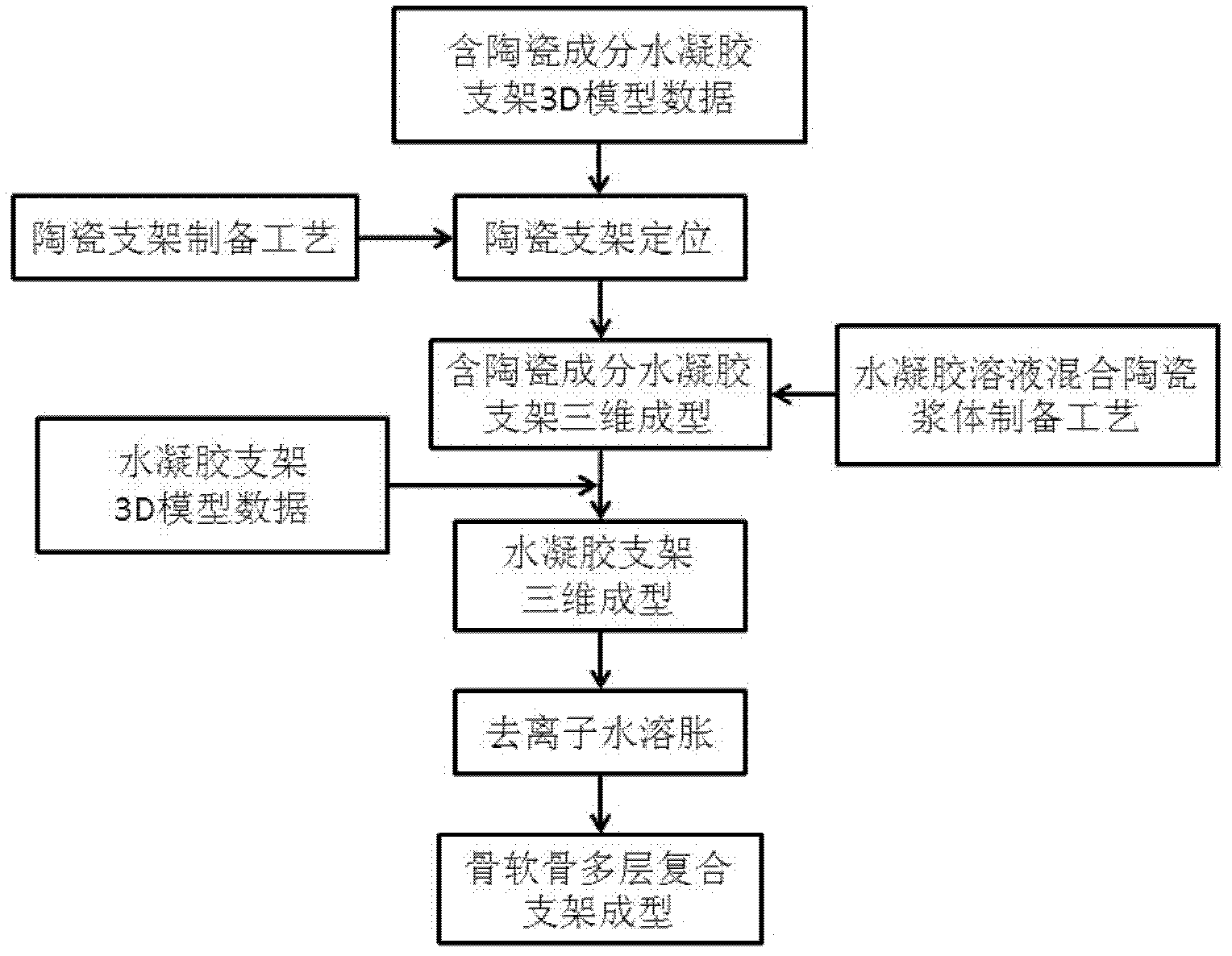

[0024] refer to figure 1 According to the light-curing rapid prototyping technology proposed in the present invention, the ceramic support prepared based on the rapid prototyping technology is used as the base, relying on its porous surface, directly forming the calcified cartilage-like layer support and the hydrogel cartilage support, and the specific steps include:

[0025] An integrated light-curing molding method for a tissue-engineered osteochondral composite scaffold, comprising the following steps:

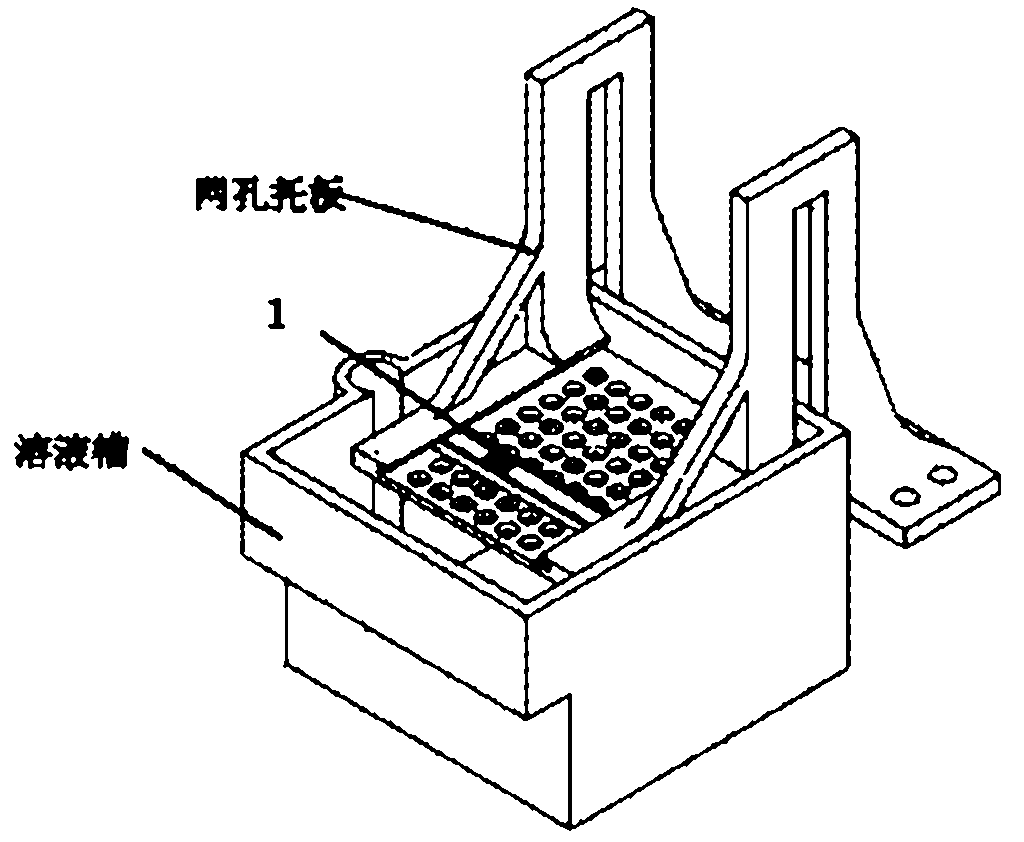

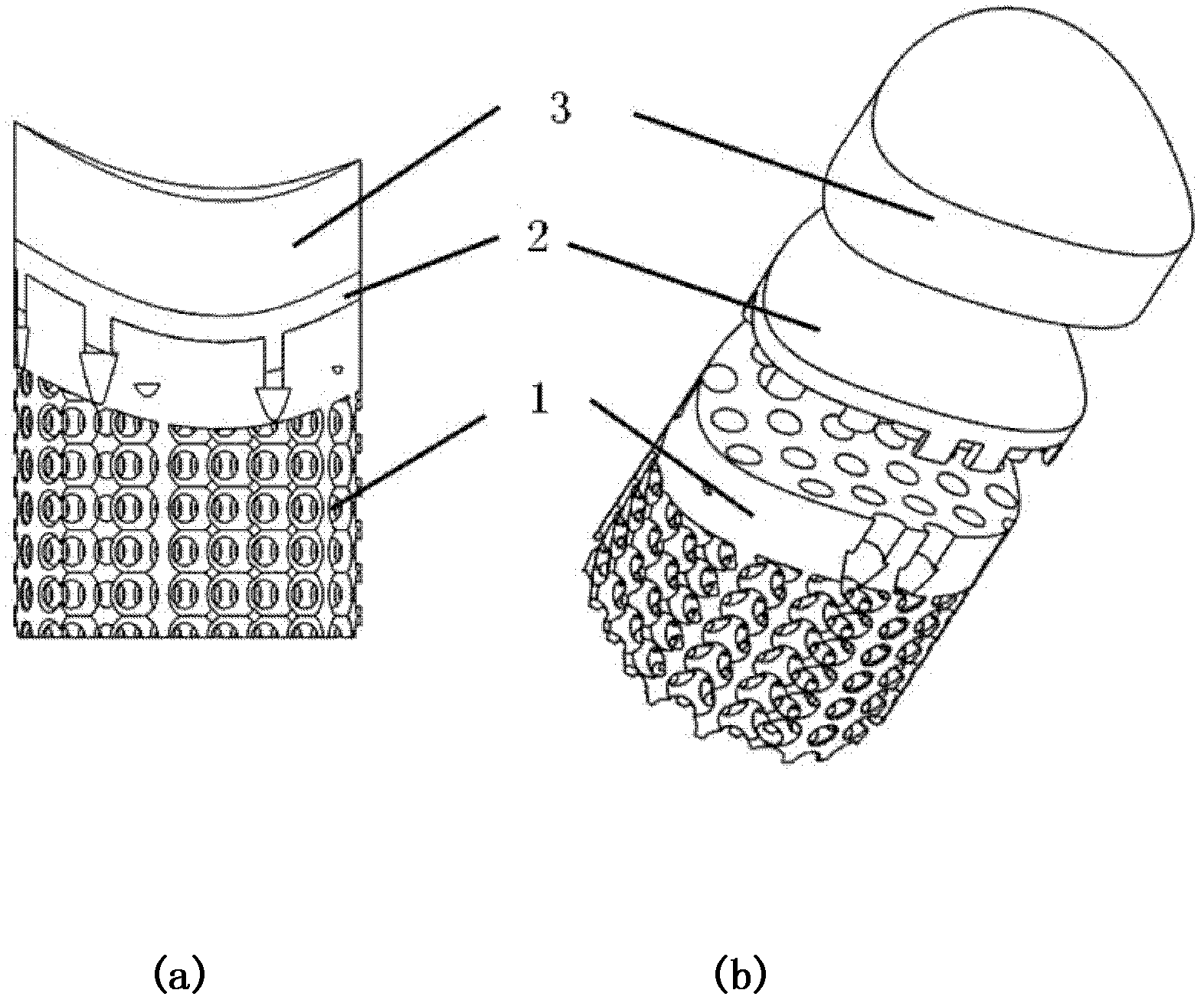

[0026] Step 1. The porous ceramic bone scaffold 1 is prepared by gel injection molding or photocuring molding technology or other methods, and pores with a diameter of not less than 200 μm are evenly distributed on the surface of the porous ceramic bone scaffold 1;

[0027] Porous ceramic bone scaffold 1 According to the requirements of the implanted site...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com