Heat pipe type end milling cutter

An end mill and heat pipe type technology, applied in the field of cutting processing, can solve the problems of reduced rigidity of the connection between the spindle and the tool holder, increased cost of cutting fluid, and affected machining accuracy, etc., to improve cutting stability, easy maintenance, and flexible use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

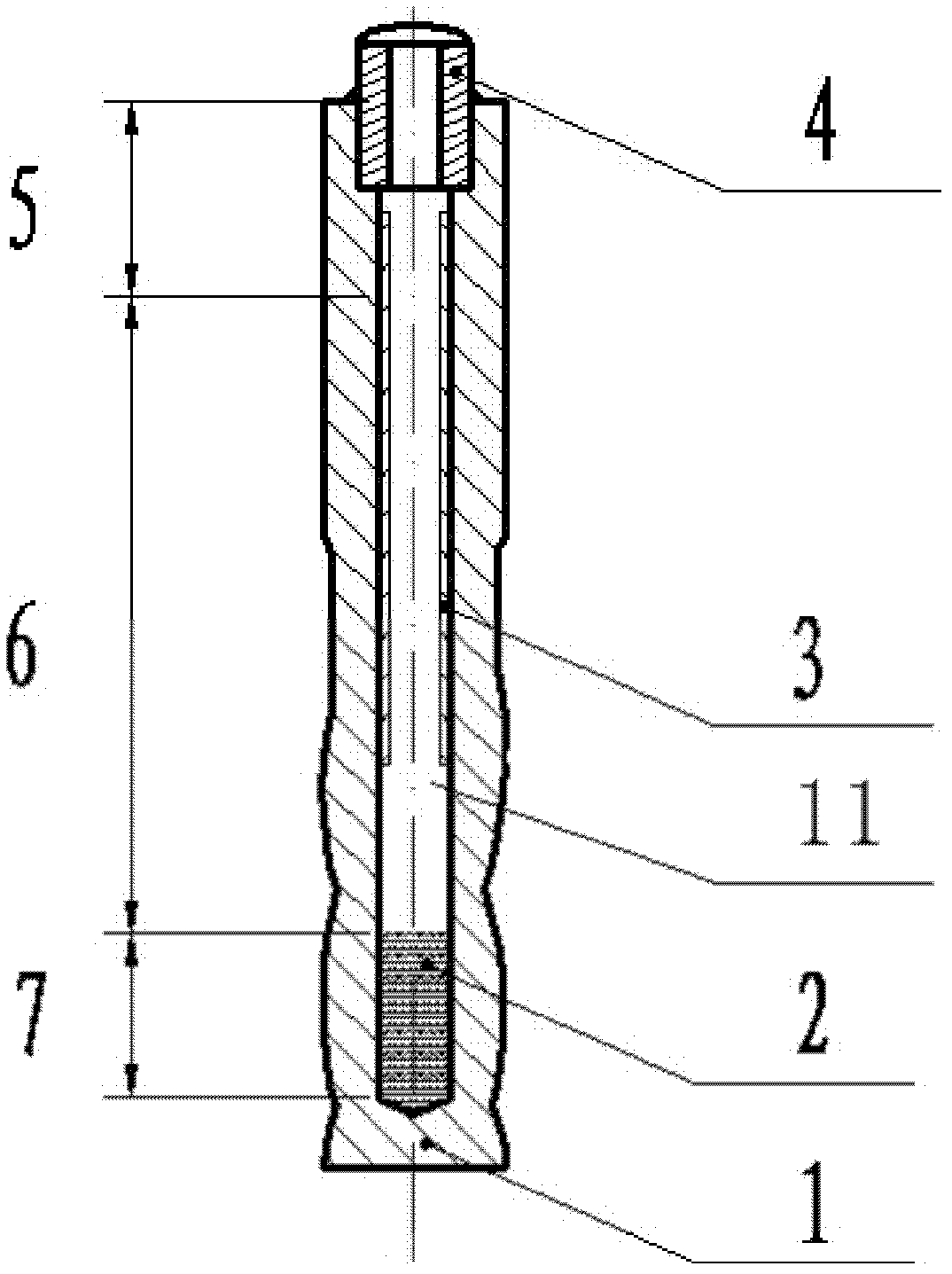

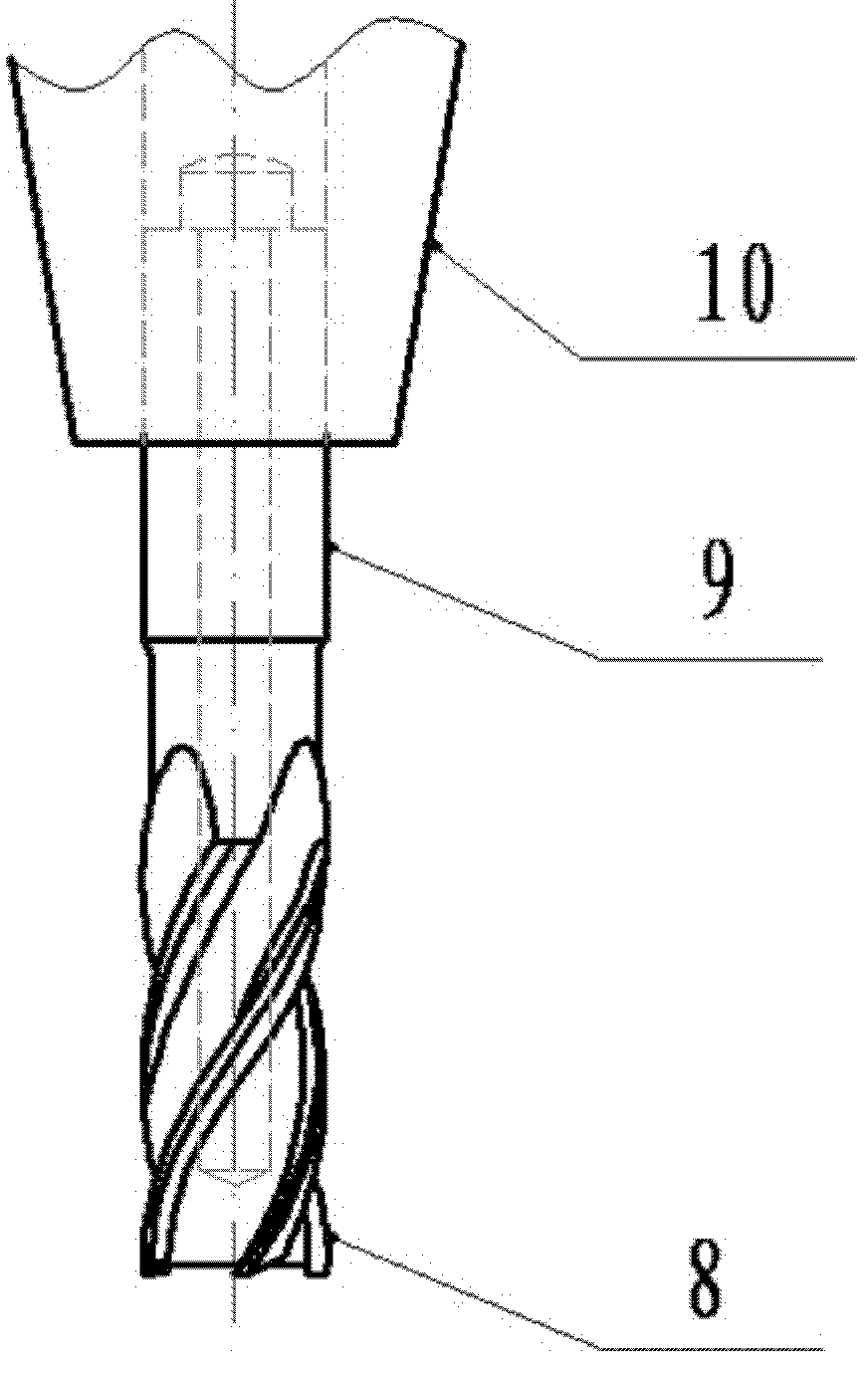

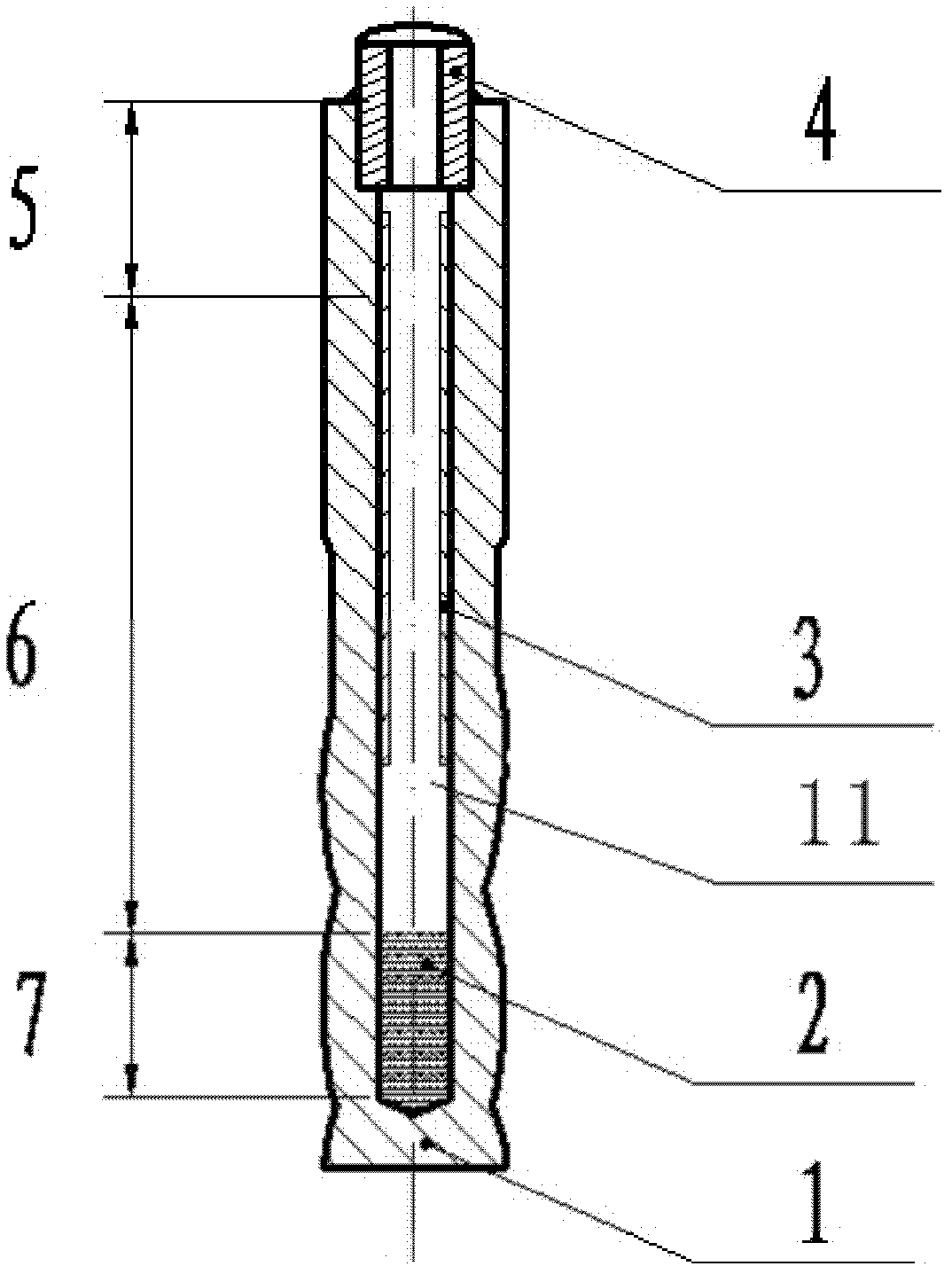

[0018] Such as figure 1 , 2 As shown, a heat pipe type end mill 1 includes a tool bar 9, the center of the tool bar 9 is provided with an axial blind hole 11, the opening end of the blind hole 11 faces the handle 10, and the blind hole 11 A liquid-absorbing core 3 is attached to the inner wall, and the opening end of the blind hole 11 is sealed with a sealing tube 4. A part of the liquid working medium 2 is housed in the blind hole 11, and the blind hole 11 is in a vacuum state.

[0019] The blind hole 11 is divided into three sections along the axial direction, the section near the milling cutter tip filled with liquid working medium 2 is the evaporation section 7 , the section near the opening end of the blind hole is the condensation section 5 , and the middle section is the adiabatic section 6 .

[0020] The liquid-absorbing core 3 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com