Hollow mesoporous silica microsphere, preparation method and application thereof

A technology of mesoporous silica and microspheres, applied in the directions of silica, silica, pharmaceutical formulations, etc., can solve the problems of limiting the application scope and application value of materials, and achieve the expansion of application value, simple preparation method, and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

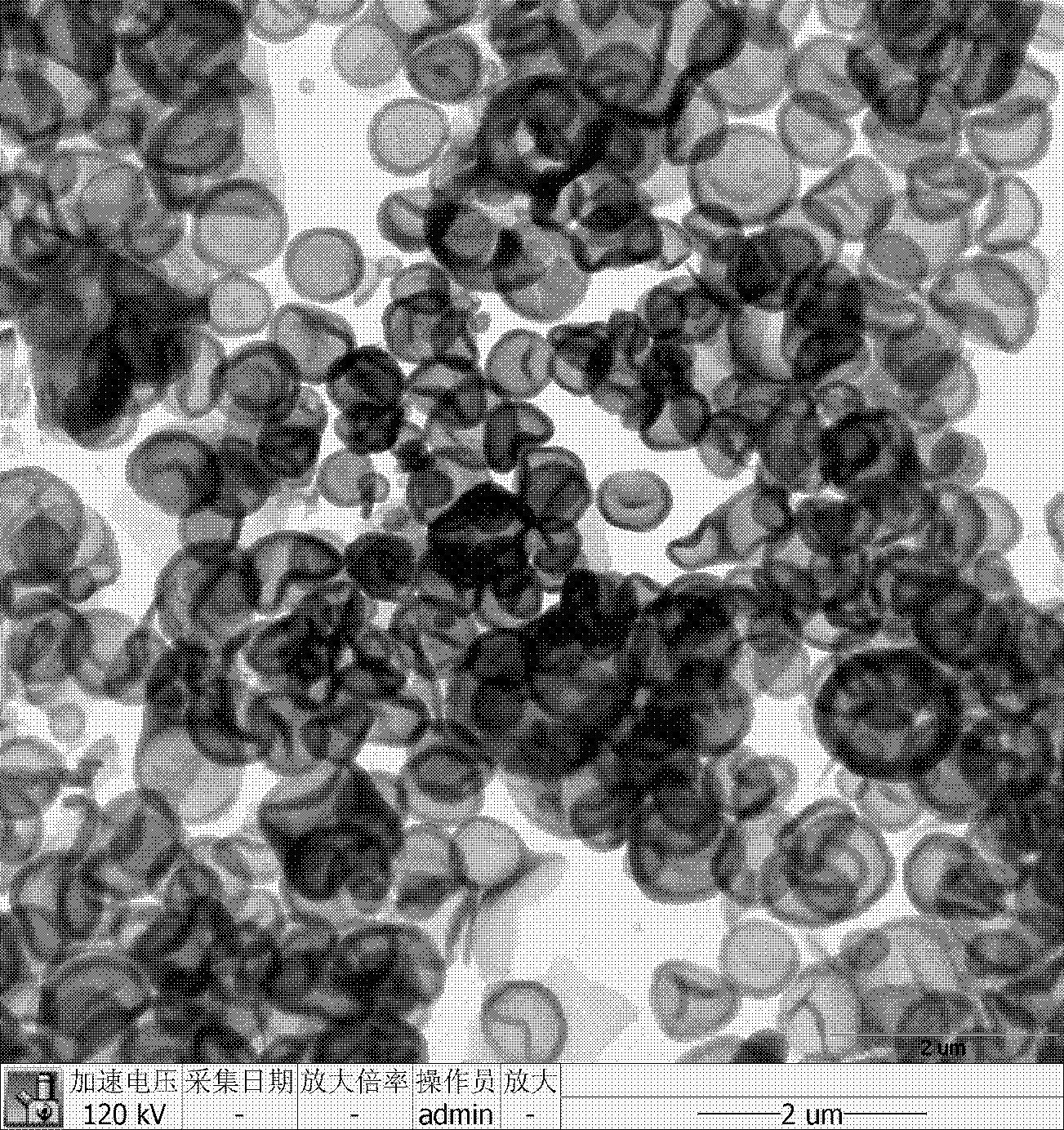

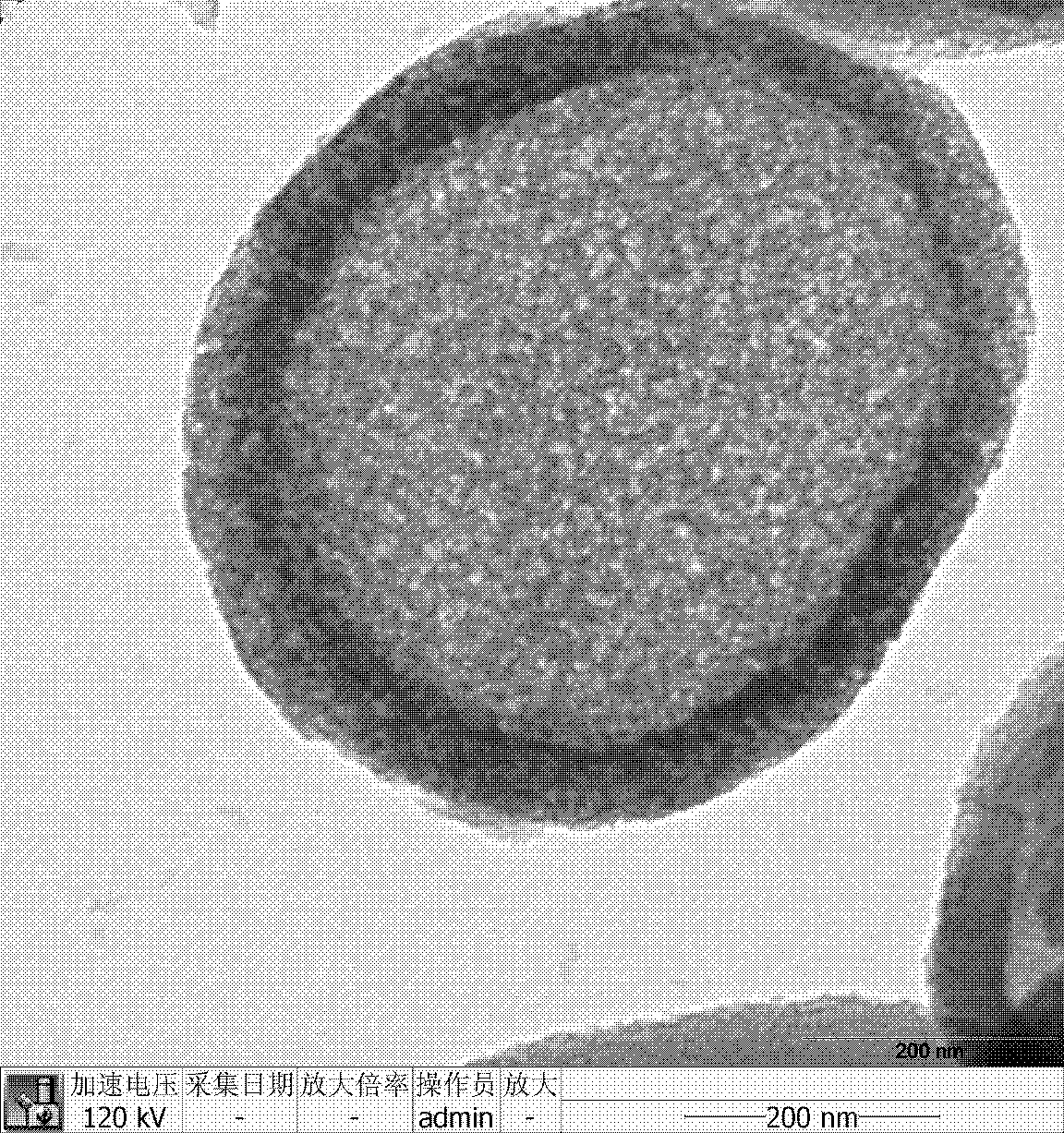

Image

Examples

Embodiment 1

[0032] The specific preparation process of the hollow mesoporous silica microspheres of this embodiment is as follows:

[0033] (1) Prepare 60ml of an ammonia solution with a pH of 12;

[0034] (2) Add cetyltrimethylammonium bromide to the aqueous ammonia solution of step (1), and the mass percentage concentration of cetyltrimethylammonium bromide in the solution is 0.5% (w / w), Stir to make the solution clear, then add n-heptane, the volume ratio of added n-heptane to ammonia is 0.1;

[0035] (3) Heating the mixed solution in step (2) at a temperature of 40°C, while stirring and emulsifying, the stirring speed is 500 rpm, and the emulsification time is 1 hour;

[0036] (4) Add ethyl orthosilicate to the mixed solution of step (3) while stirring, and the mass ratio of the added ethyl orthosilicate to cetyltrimethylammonium bromide is 1;

[0037] (5) Collect the solid by filtration after 2 hours, wash to neutral and dry;

[0038] (6) The dry powder is not calcined at 550°C for 10 hours to...

Embodiment 2

[0042] The specific preparation process of the hollow mesoporous silica microspheres of this embodiment is as follows:

[0043] (1) Prepare 60ml of ammonia solution with pH 10;

[0044] (2) Add cetyltrimethylammonium bromide to the aqueous ammonia solution of step (1), and the mass percentage concentration of cetyltrimethylammonium bromide in the solution is 0.1% (w / w), Stir to make the solution clear, then add a mixture of isooctane and n-decane, the volume ratio of the added mixture to ammonia is 0.2;

[0045] (3) Heating the mixed solution in step (2) at a temperature of 30°C, while stirring and emulsifying, the stirring speed is 700 rpm, and the emulsification time is 2 hours;

[0046] (4) Add ethyl orthosilicate to the mixed solution of step (3) while stirring, and the mass ratio of the added ethyl orthosilicate to cetyltrimethylammonium bromide is 0.05;

[0047] (5) Collect the solid by filtration after 2 hours, wash to neutral and dry;

[0048] (6) The dry powder is not calcined ...

Embodiment 3

[0051] The specific preparation process of the hollow mesoporous silica microspheres of this embodiment is as follows:

[0052] (1) Prepare 60ml of 0.5M hydrochloric acid solution;

[0053] (2) Add PEO-PPO-PEO triblock copolymer P123 to the hydrochloric acid solution of step (1), and the mass percentage concentration of PEO-PPO-PEO triblock copolymer P123 in the solution is 5.0% (w / w ), stir to make the solution clear, then add a mixture of 1,3,5-trimethylbenzene and isooctane, the volume ratio of the added mixture to ammonia is 0.01;

[0054] (3) Heating the mixed solution in step (2) at a temperature of 80°C, while stirring and emulsifying, the stirring speed is 200 rpm, and the emulsification time is 0.5 hours;

[0055] (4) Add ethyl orthosilicate to the mixed solution of step (3) while stirring, and the mass ratio of the added ethyl orthosilicate to P123 is 0.05;

[0056] (5) Collect the solid by filtration after 2 hours, wash to neutral and dry;

[0057] (6) The dry powder was not ...

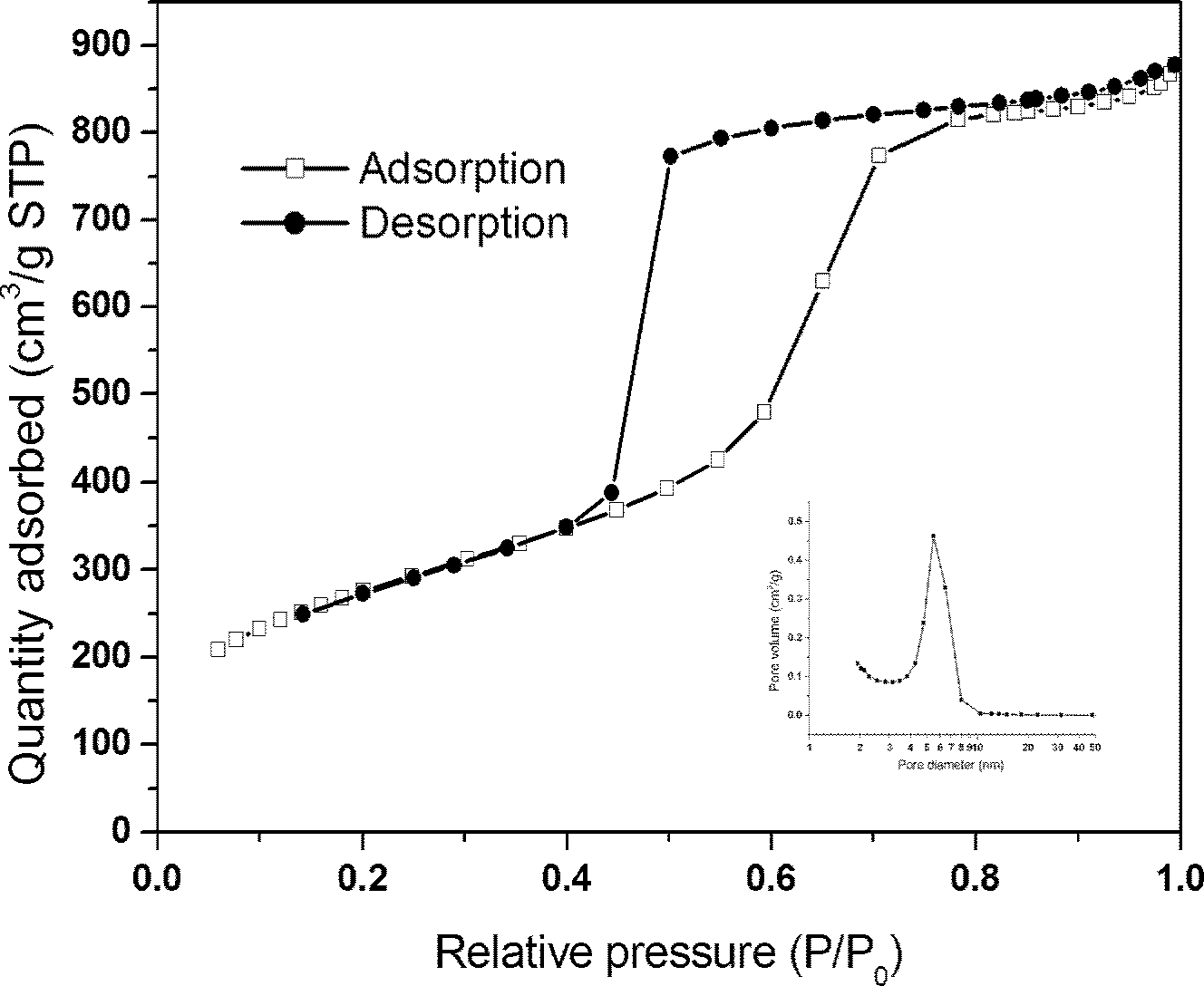

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com