Preparation method of neutral nano titanium dioxide hydrosol for functional fabric

A technology of nano-titanium dioxide and functional fabrics, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of no affinity for fibers, unstable dispersion, and difficult to fix fabrics, etc., and achieve low production costs and easy large-scale Large-scale production and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Features: The degumming temperature is 20°C, 60°C, 90°C and stirred for 3 hours to prepare TiO 2 Sol.

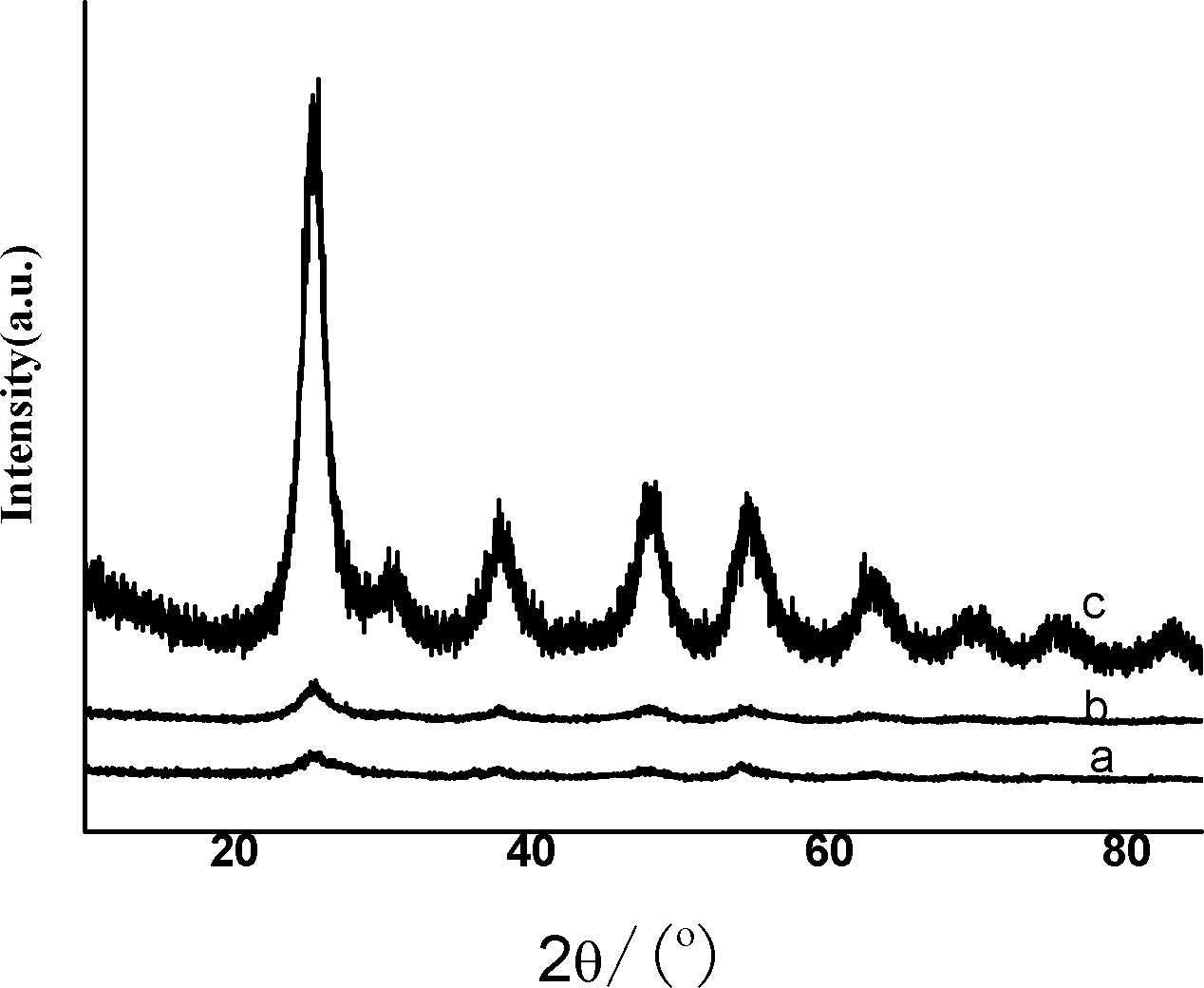

[0036] In a water bath at 5°C, measure 6mL of TiCl 4 Add 50 mL of deionized water dropwise, stir during the dropping process, and control the dropping speed at the same time to ensure the complete hydrolysis reaction; stir for 1 hour to obtain a uniform transparent solution. Add a certain amount of sodium hydroxide solution to adjust the pH to about 7. After aging for a period of time, filter and fully wash with deionized water for 6-8 times to remove Cl in the solution -, take out the filter cake, add some deionized water, then add a certain amount of hydrochloric acid solution, control its concentration to be 5wt%, and adjust the pH to about 1.5. Then stirred at 20°C, 60°C, and 90°C for 3 hours to obtain transparent TiO with blue light 2 Sol. figure 1 TiO made at 20°C, 60°C, and 90°C for degumming temperature 2 In the XRD pattern, a is 20°C, b is 60°C, and c i...

Embodiment 2

[0038] Features: Nano-TiO made with non-ionic polyvinylpyrrolidone as modifier 2 Hydrosol.

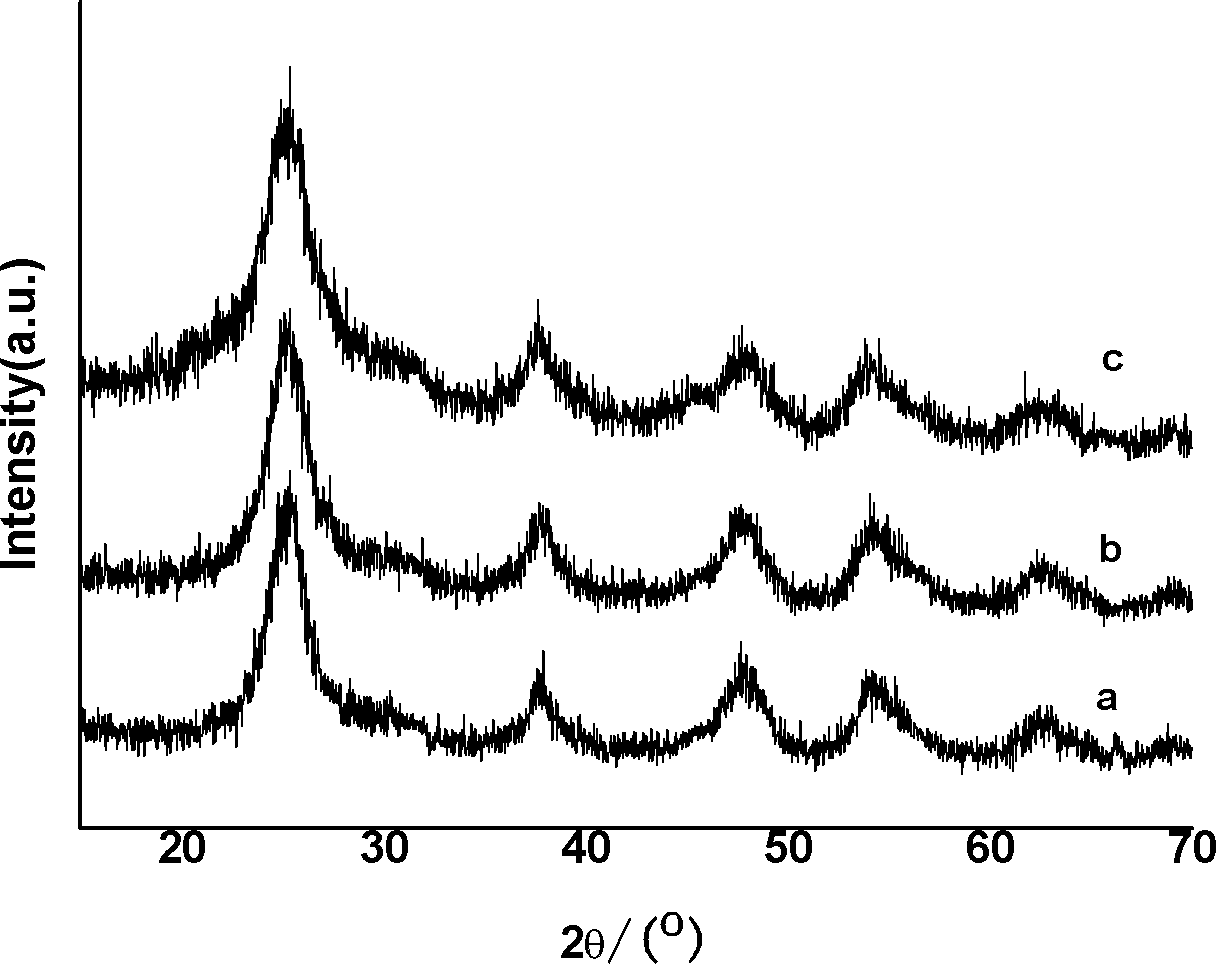

[0039] In a water bath at 5°C, measure 6mL of TiCl 4 Add 50 mL of deionized water dropwise, stir during the dropping process, and control the dropping speed at the same time to ensure the complete hydrolysis reaction; stir for 1 hour to obtain a uniform transparent solution. Add a certain amount of sodium hydroxide solution to adjust the pH to about 7. After aging for a period of time, filter and wash 6-8 times with deionized water to fully remove the Cl in the solution - , take out the filter cake, add some deionized water, then add a certain amount of hydrochloric acid solution, adjust the pH to about 1.5, and control its concentration to be 30wt%. Then add a certain mass of polyvinylpyrrolidone and degumming at 60°C for 3 hours to obtain transparent TiO with blue light. 2 Sol. figure 2 XRD patterns of titanium dioxide modified by polyvinylpyrrolidone with concentrations of 0.5...

Embodiment 3

[0041] Features: Nano-TiO made with KH-550 as modifier 2 Hydrosol.

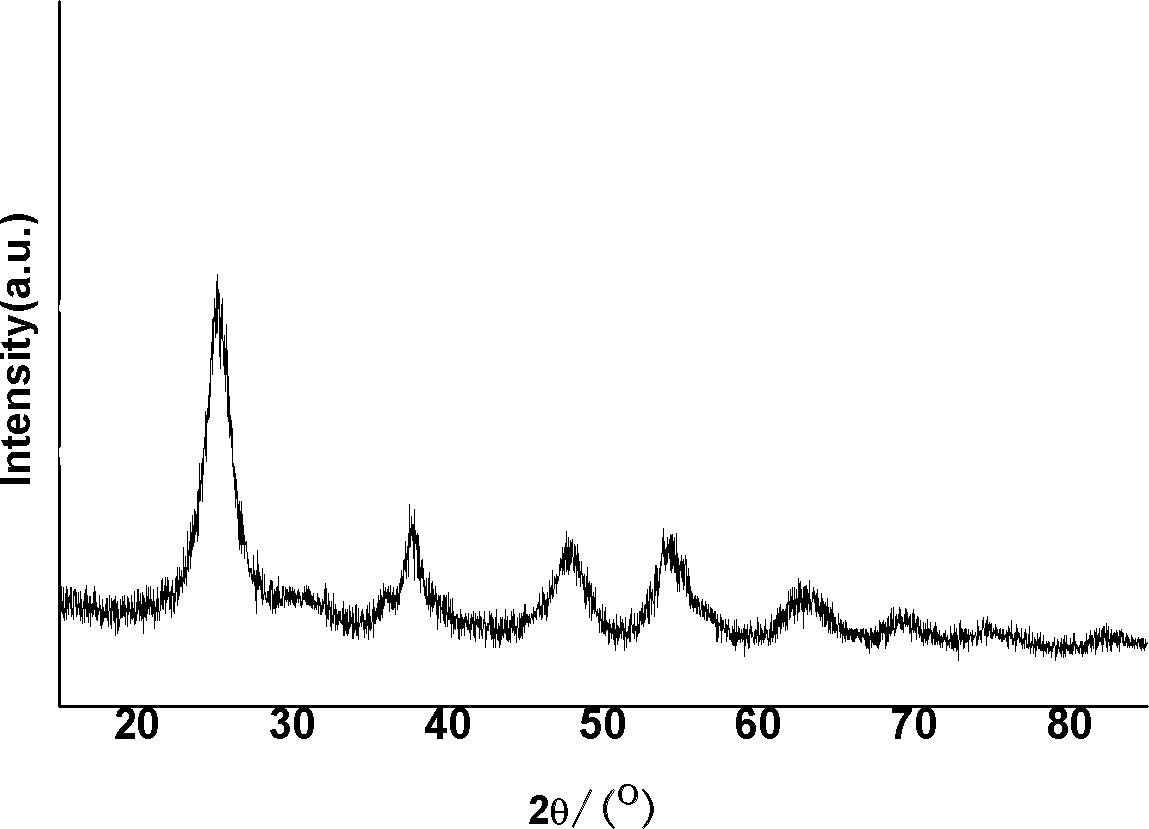

[0042] In a water bath at 5°C, measure 6mL of TiCl 4 Add 50 mL of deionized water dropwise, stir during the dropping process, and control the dropping speed at the same time to ensure the complete hydrolysis reaction; stir for 1 hour to obtain a uniform transparent solution. Add a certain amount of sodium hydroxide solution to adjust the pH to about 7. After aging for a period of time, filter and wash 6-8 times with deionized water to fully remove the Cl in the solution - , take out the filter cake, add some deionized water, and then add a certain amount of hydrochloric acid solution to adjust the pH to about 1.5. Then add a certain quality of KH-550 and degumming at 60°C for 3 hours to obtain transparent neutral TiO with blue light. 2 Sol. image 3 XRD pattern for titanium dioxide made with KH-550 at a concentration of 0.5%. At this time, the crystal form is anatase type, and the average grain size is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com